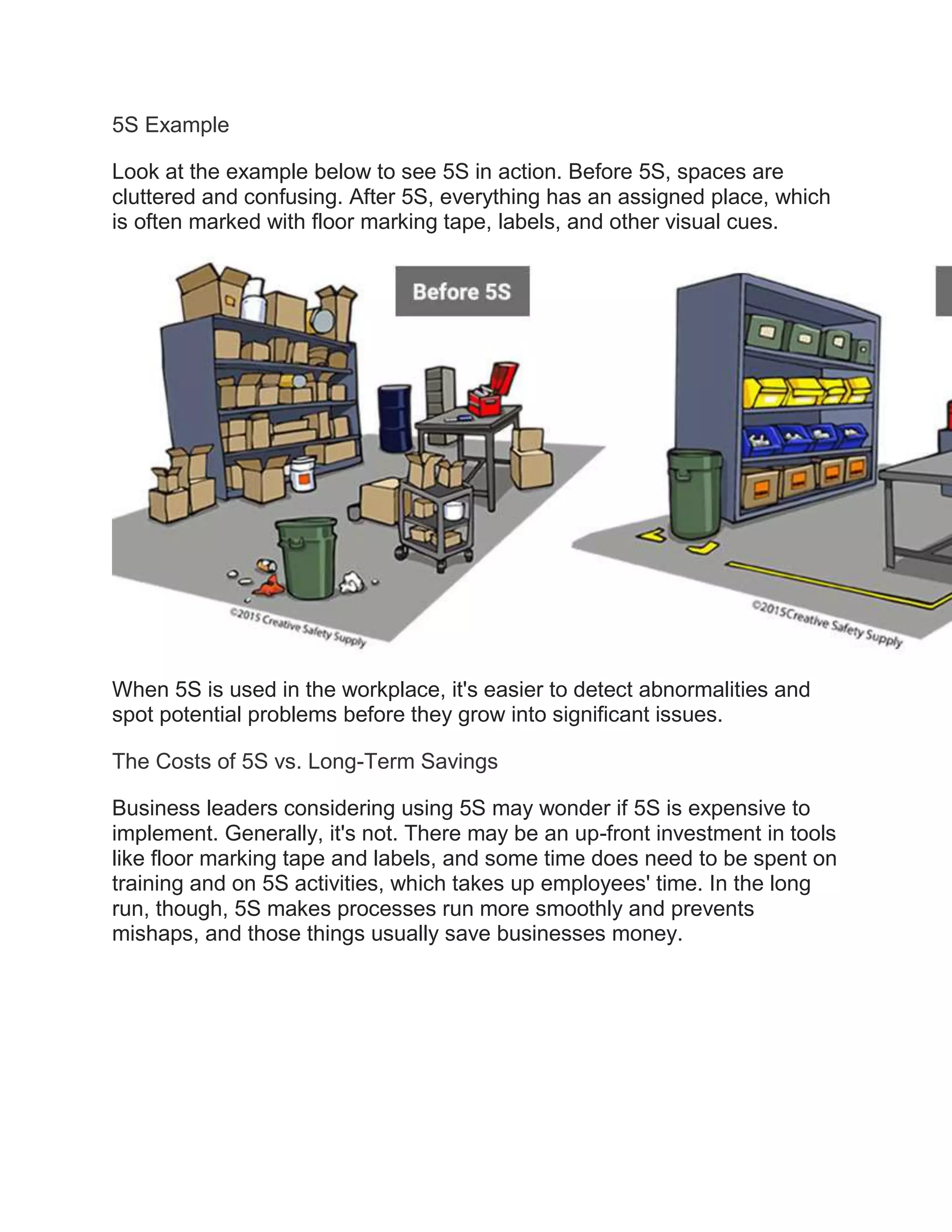

5S is a system for organizing workspaces that focuses on putting everything in its proper place and keeping areas clean. It originated in Japanese manufacturing but has expanded to other industries. The 5S methodology involves sorting, setting in order, shining, standardizing, and sustaining these practices. Visual tools like labels, tapes and boards are used to clearly indicate where items belong. While initial costs exist, 5S implementation leads to long-term benefits like reduced costs, higher quality, and a safer work environment.