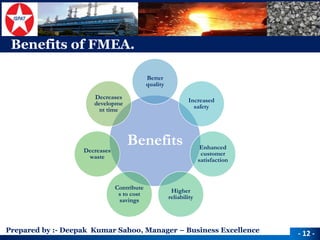

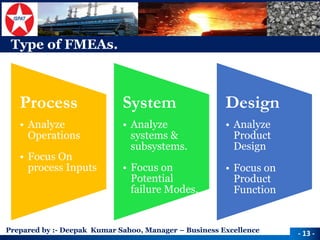

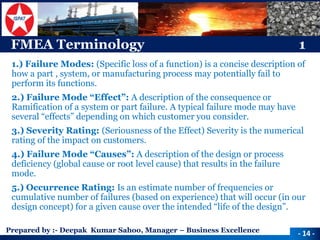

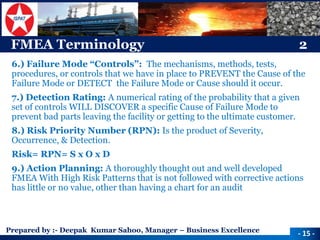

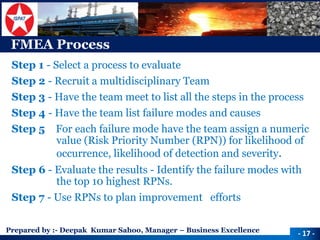

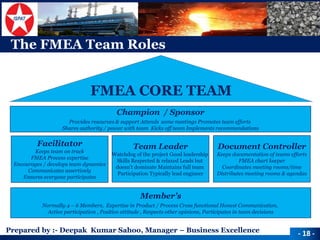

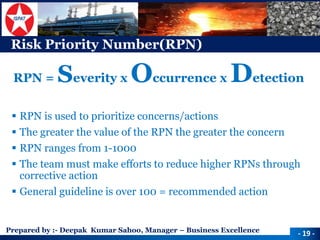

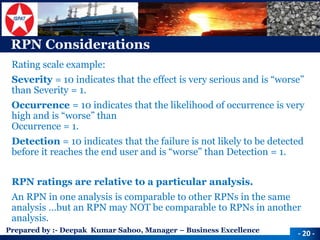

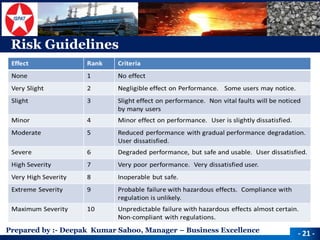

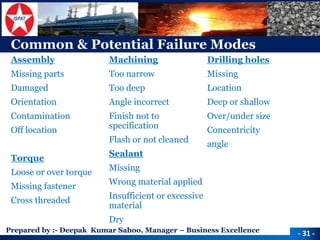

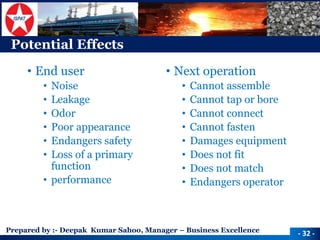

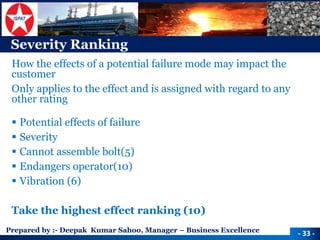

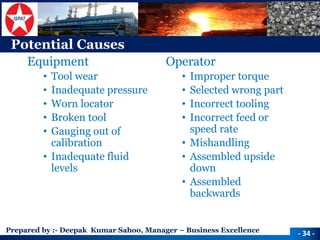

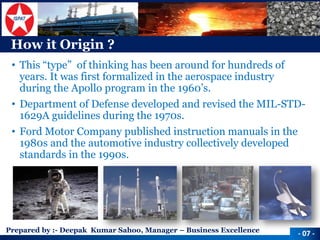

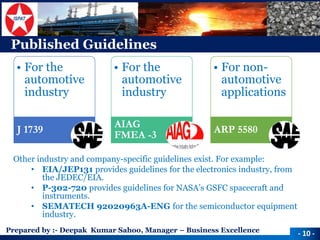

The document outlines the Failure Mode and Effects Analysis (FMEA) process, detailing its history, definitions, and systematic approach towards identifying and mitigating potential failure risks in products and processes. It highlights the benefits of implementing FMEA, such as improved quality and safety, and emphasizes the importance of a multidisciplinary team during the analysis. Additionally, it provides insights into the scoring system used to prioritize risks and recommend actions for prevention and improvement.

![Prepared by :-Deepak Kumar Sahoo, Manager –Business Excellence

Rule of Ten (10)

-11 -

[ $ 10 ]

Discovered During Design/ Process Engineering

[ $ 100 ]

Discovered During incoming inspection.

[ $ 1000 ]

Discovered During the final test

[ $ 10000 ]

Discovered in the field](https://image.slidesharecdn.com/fmeabaldeepaksahoo-141109111300-conversion-gate01/85/FMEA_BAL_Deepak_Sahoo-14-320.jpg)