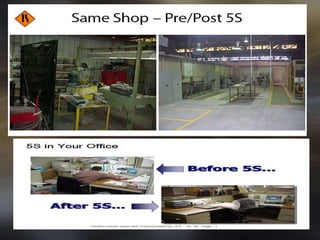

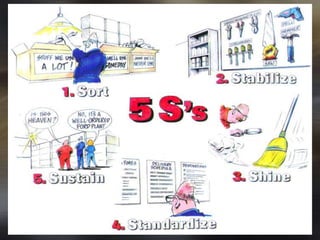

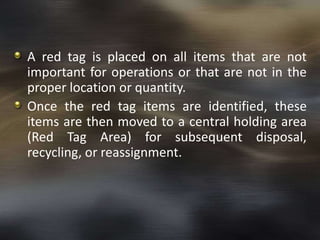

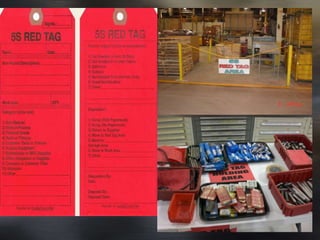

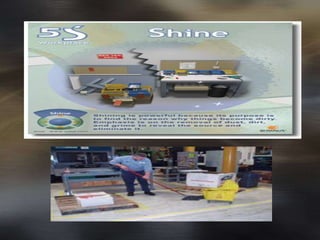

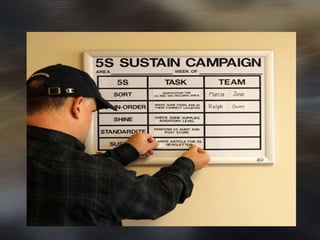

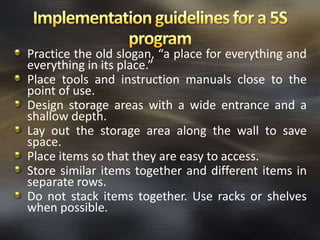

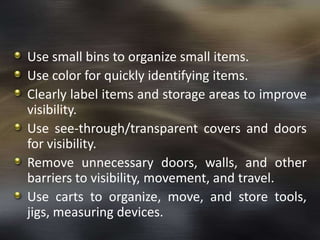

This document discusses the 5S methodology, which is a lean manufacturing technique used to establish order and cleanliness in the workplace. It summarizes the five steps of 5S as: Sort, Set in Order, Shine, Standardize, and Sustain. Each step is defined, with Sort focusing on removing unnecessary items, Set in Order creating efficient storage, Shine thoroughly cleaning, Standardize preventing issues, and Sustain making the changes a habit. Examples are provided of how cluttered workspaces can be organized by establishing storage areas and labeling items to create a clean and productive work environment through implementing 5S.