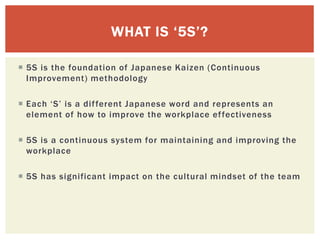

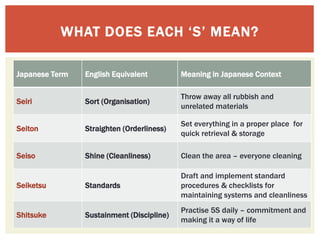

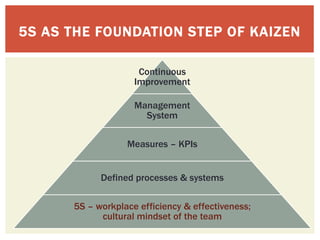

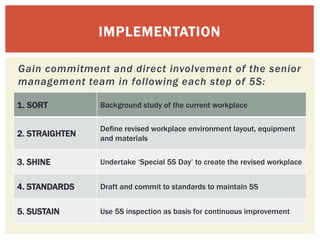

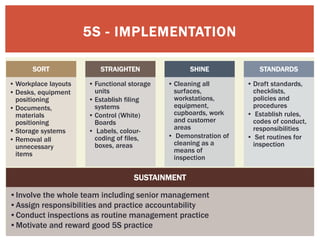

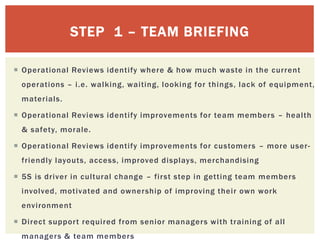

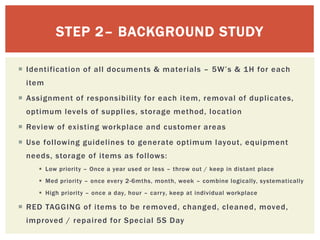

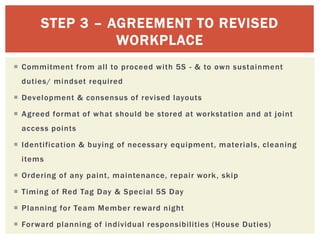

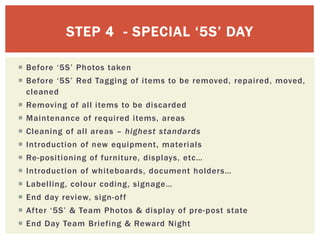

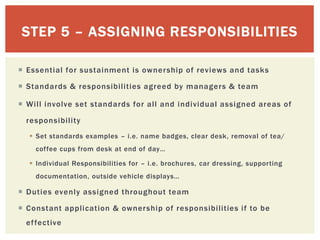

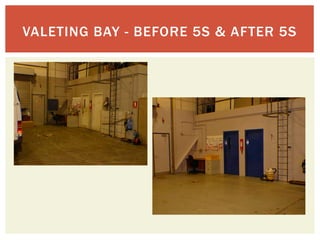

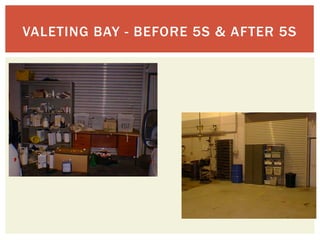

The document outlines the steps to implement the 5S methodology in a workplace. It begins by explaining the 5S principles of sorting, straightening, shining, standardizing, and sustaining. It then details the 6 steps to implement 5S: 1) briefing the team, 2) conducting a background study, 3) agreeing on a revised workplace layout, 4) holding a special 5S day to create the new layout, 5) assigning responsibilities, and 6) incorporating 5S into daily business practices. Examples are provided showing a valeting bay before and after applying 5S principles.