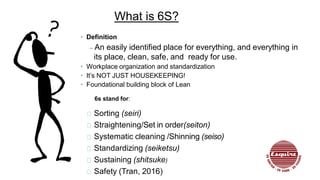

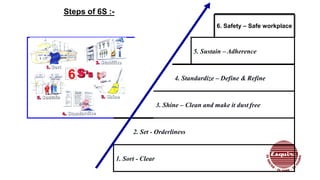

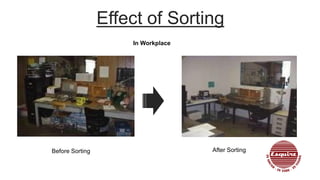

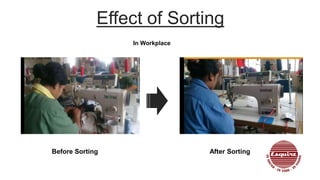

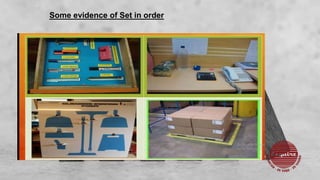

The document introduces the concept of 6S, which stands for Sort, Set in order, Shine, Standardize, Sustain, and Safety, emphasizing workplace organization and efficiency. It outlines the steps and benefits of implementing 6S, including improved safety, reduced waste, and enhanced productivity. Additionally, it highlights the importance of maintaining standards through regular training and discipline to sustain the 6S practices in the workplace.