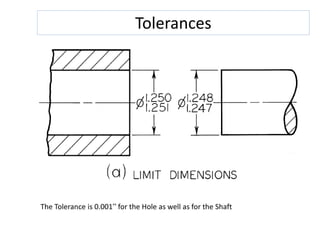

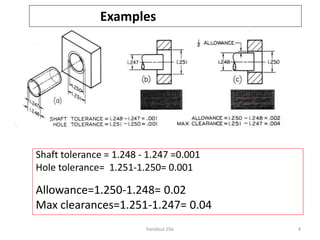

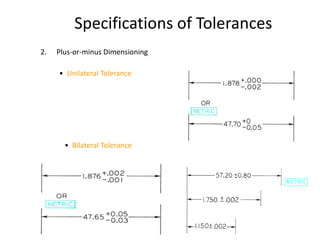

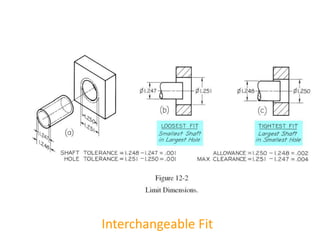

This document discusses tolerances, allowances, and fits between parts. It defines tolerance as the permissible variation in a dimension, given as the difference between maximum and minimum limits. Tolerances are necessary due to variations in materials and machines. The document provides examples of shaft and hole tolerances of 0.001 inches each, resulting in a clearance of 0.004 inches maximum. Allowance is defined as the intentional difference between the lower hole limit and higher shaft limit, ensuring the proper fit. The key difference between tolerance and allowance is that tolerance refers to variation within a single part, while allowance refers to the relationship between mating parts.