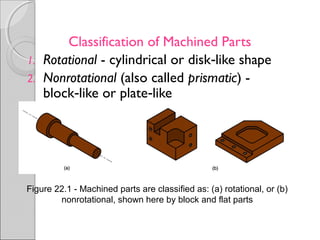

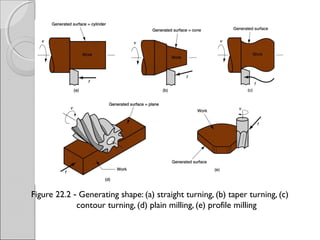

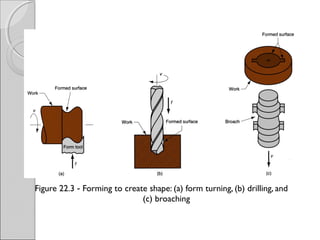

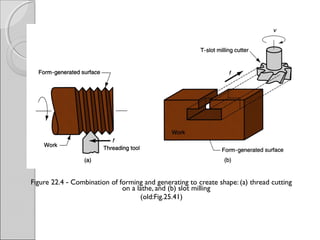

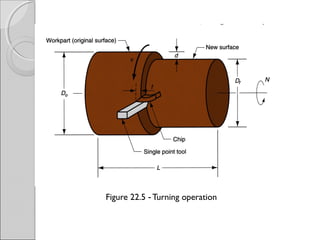

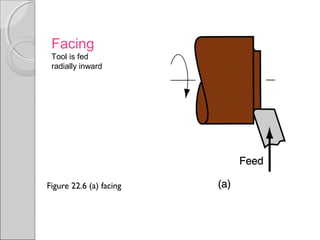

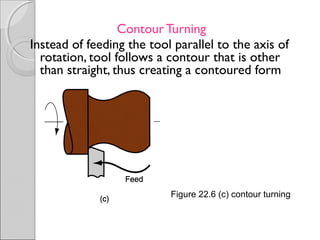

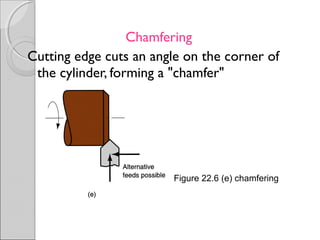

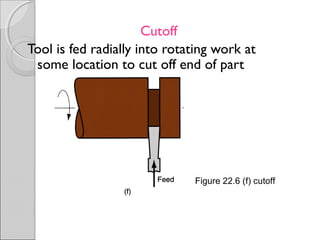

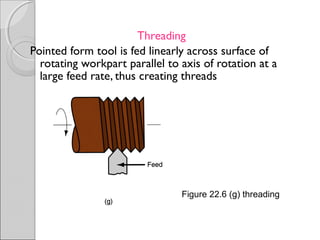

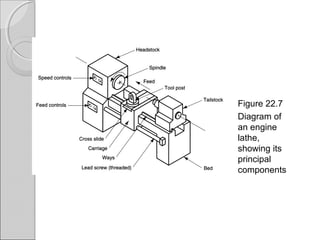

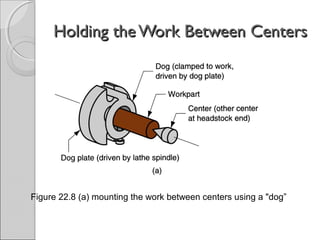

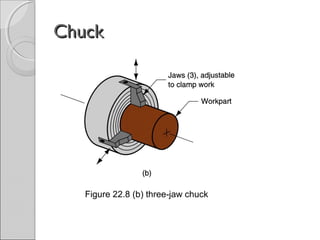

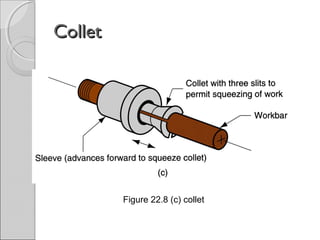

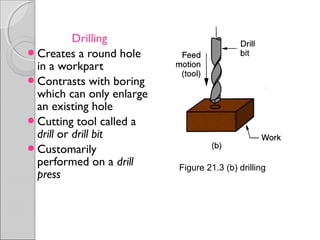

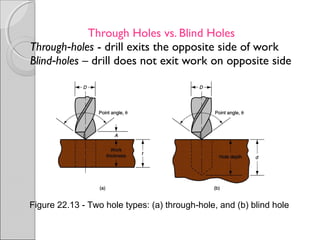

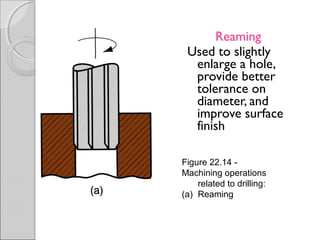

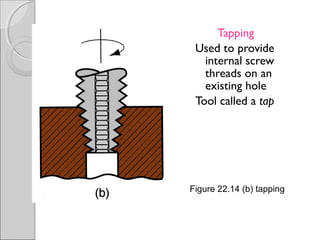

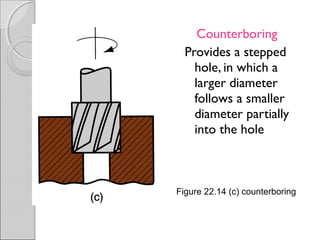

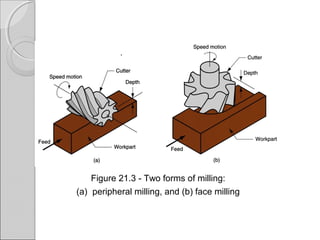

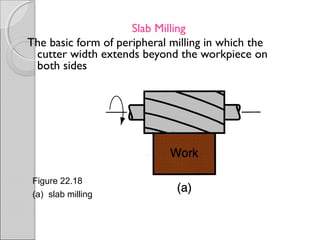

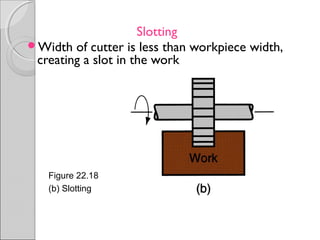

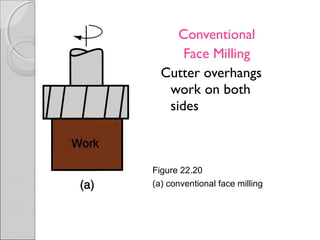

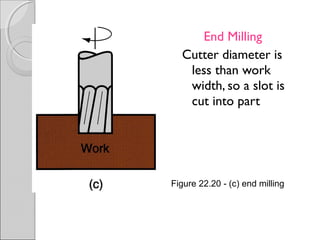

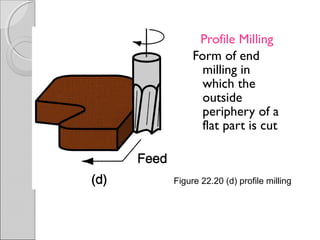

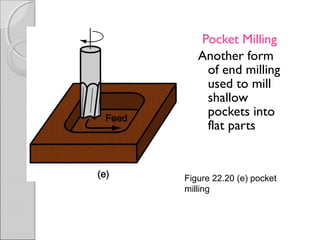

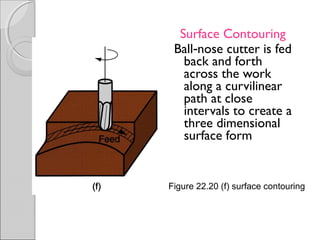

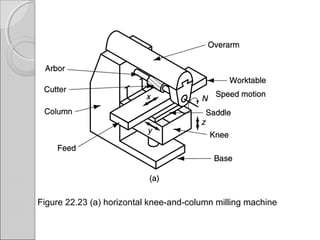

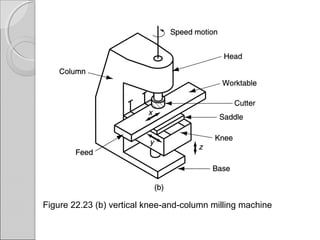

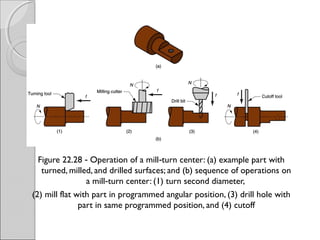

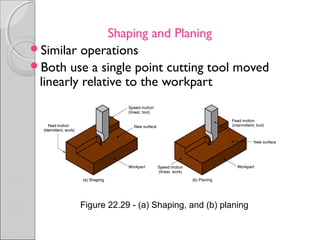

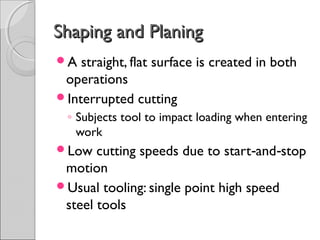

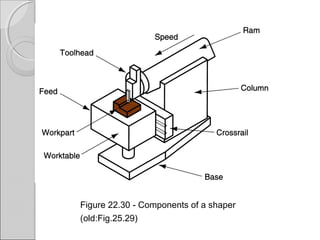

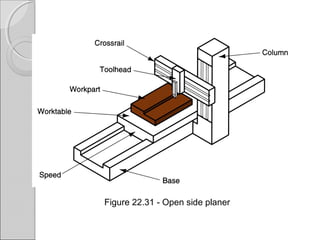

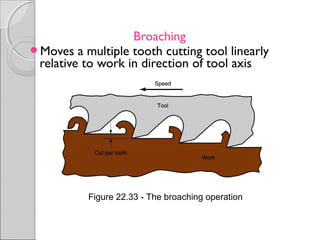

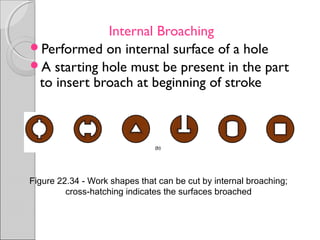

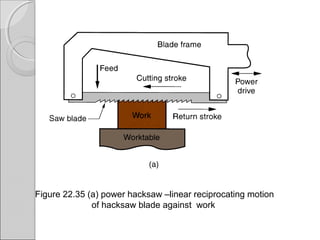

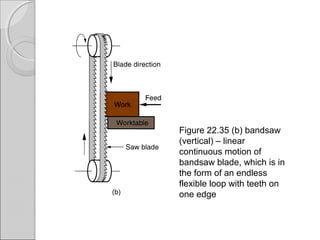

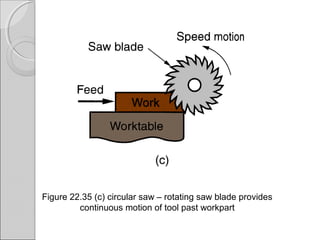

This document provides an overview of various machining operations including turning, drilling, milling, and others. It defines machining as a material removal process using sharp cutting tools. The main machining operations covered are turning operations on lathes such as facing, contour turning, and threading. Drilling operations like through holes, blind holes, reaming and tapping are also discussed. Milling operations like peripheral milling, face milling, end milling, and contour milling are summarized. The document also briefly covers other operations like shaping, planning, broaching, and sawing. It includes diagrams to illustrate the different operations.