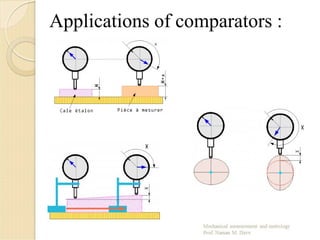

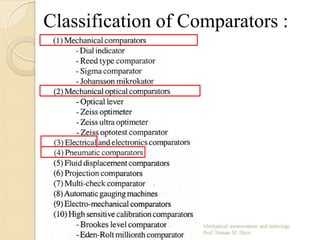

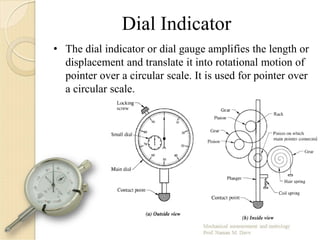

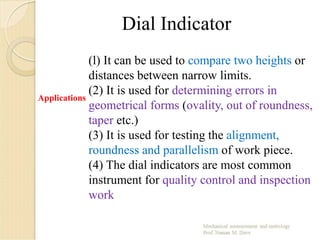

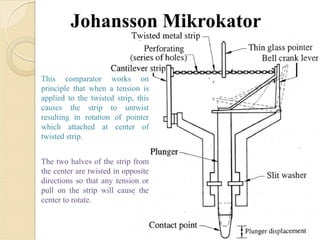

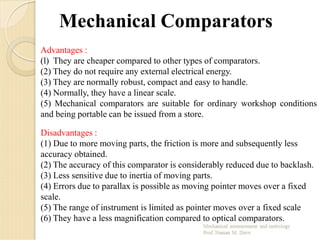

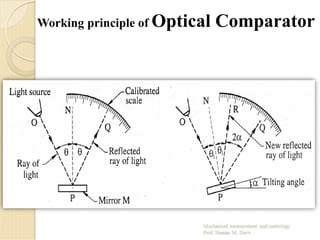

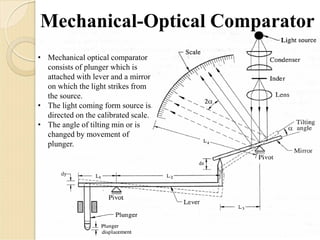

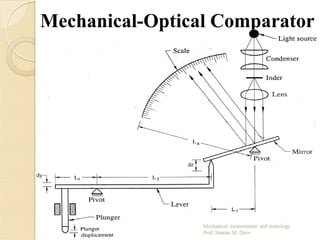

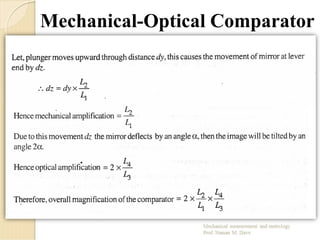

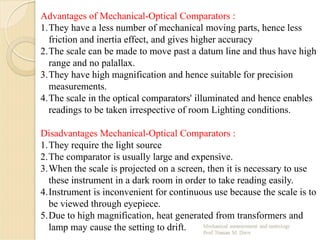

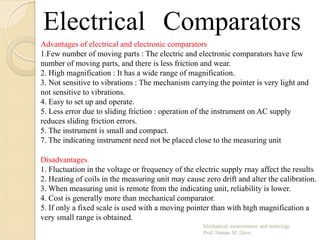

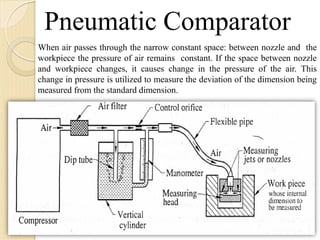

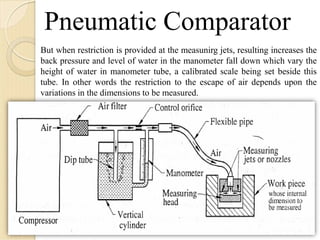

The document provides an in-depth overview of comparators, precision instruments used to compare dimensions of workpieces against master standards. It outlines their characteristics, advantages, disadvantages, and various types, such as mechanical, optical, electrical, and pneumatic comparators, along with their applications in mass production and quality control. The importance of attributes like robustness, sensitivity, and quick result delivery in comparators is emphasized for effective measurement and inspection.