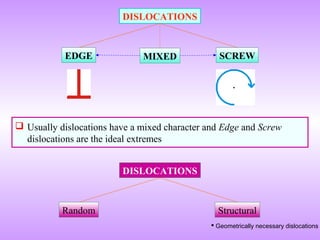

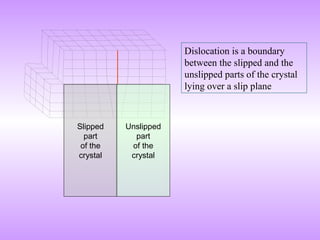

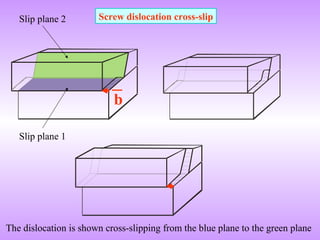

Dislocations are line defects in crystals that represent disrupted planes of atoms. They allow plastic deformation via slip along crystallographic planes and directions.

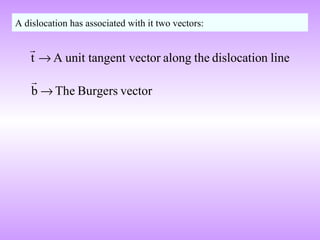

A dislocation is characterized by its Burgers vector, which represents the lattice displacement caused by the dislocation and determines the direction of slip. The Burgers vector connects one lattice position to another.

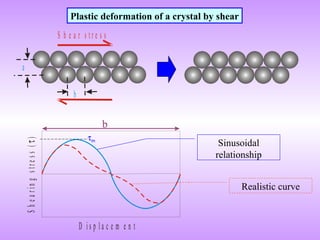

Dislocations lower the theoretical shear strength of crystals by several orders of magnitude, enabling plasticity. Their motion through glide and climb allows crystals to deform plastically under stress.

![Screw dislocation

[1]

[1] Bryan Baker

chemed.chem.purdue.edu/genchem/ topicreview/bp/materials/defects3.html -](https://image.slidesharecdn.com/crystalimperfectionsdislocations-141128112856-conversion-gate02/85/Crystal-imperfections-dislocations-20-320.jpg)

![Motion of a mixed dislocation

[1] http://www.tf.uni-kiel.de/matwis/amat/def_en/kap_5/backbone/r5_1_2.html

[1]

We are looking at the plane of the cut (sort of a semicircle centered in the lower left corner). Blue circles denote

atoms just below, red circles atoms just above the cut. Up on the right the dislocation is a pure edge dislocation

on the lower left it is pure screw. In between it is mixed. In the link this dislocation is shown moving in an

animated illustration.](https://image.slidesharecdn.com/crystalimperfectionsdislocations-141128112856-conversion-gate02/85/Crystal-imperfections-dislocations-25-320.jpg)

![Dissociation of dislocations

Consider the reaction:

2b → b + b

Change in energy:

G(2b)2/2 → 2[G(b)2/2]

G(b)2

Þ The reaction would be favorable](https://image.slidesharecdn.com/crystalimperfectionsdislocations-141128112856-conversion-gate02/85/Crystal-imperfections-dislocations-28-320.jpg)

![2

1 211

6

b = éë ùû

3

1 12 1

6

b = éë ùû

1

(111)

1 110

2

b = éë ùû

(111)

Slip plane

(111)

1 [110]

2

1 [121]

6

æ ö

çè ø¸ (111)

æ ö

çè ø¸ (111)

1 [211]

6

æ ö

çè ø¸ → +

b1

2 > (b2

2 + b3

2)

½ > ⅓

FCC

Shockley Partials

A

B

C

(111)

(111)

Some of the atoms are omitted for clarity

(111)

1 [12 1]

6

æ ö

çè ø¸

(111)

1 [211]

6

æ ö

çè ø¸](https://image.slidesharecdn.com/crystalimperfectionsdislocations-141128112856-conversion-gate02/85/Crystal-imperfections-dislocations-29-320.jpg)

![BCC Pure edge dislocation

Dislocation line vector

(110)

(110),(111)

1 [1 1 1]

2

æ ö

çè ø¸

1 [112]

2

æ ö

çè ø¸

(111)

(1 10)

Slip plane

Extra half plane

Burger’s vector

1 [111]

1 2 112

2

éë ùû

(110)](https://image.slidesharecdn.com/crystalimperfectionsdislocations-141128112856-conversion-gate02/85/Crystal-imperfections-dislocations-31-320.jpg)

![Slip systems

Crystal Slip plane(s) Slip direction

FCC {111} <110>

HCP (0001) <11`20>

BCC

Not close packed {110}, {112}, {123} [111]

No clear choice

Þ Wavy slip lines

Anisotropic](https://image.slidesharecdn.com/crystalimperfectionsdislocations-141128112856-conversion-gate02/85/Crystal-imperfections-dislocations-35-320.jpg)