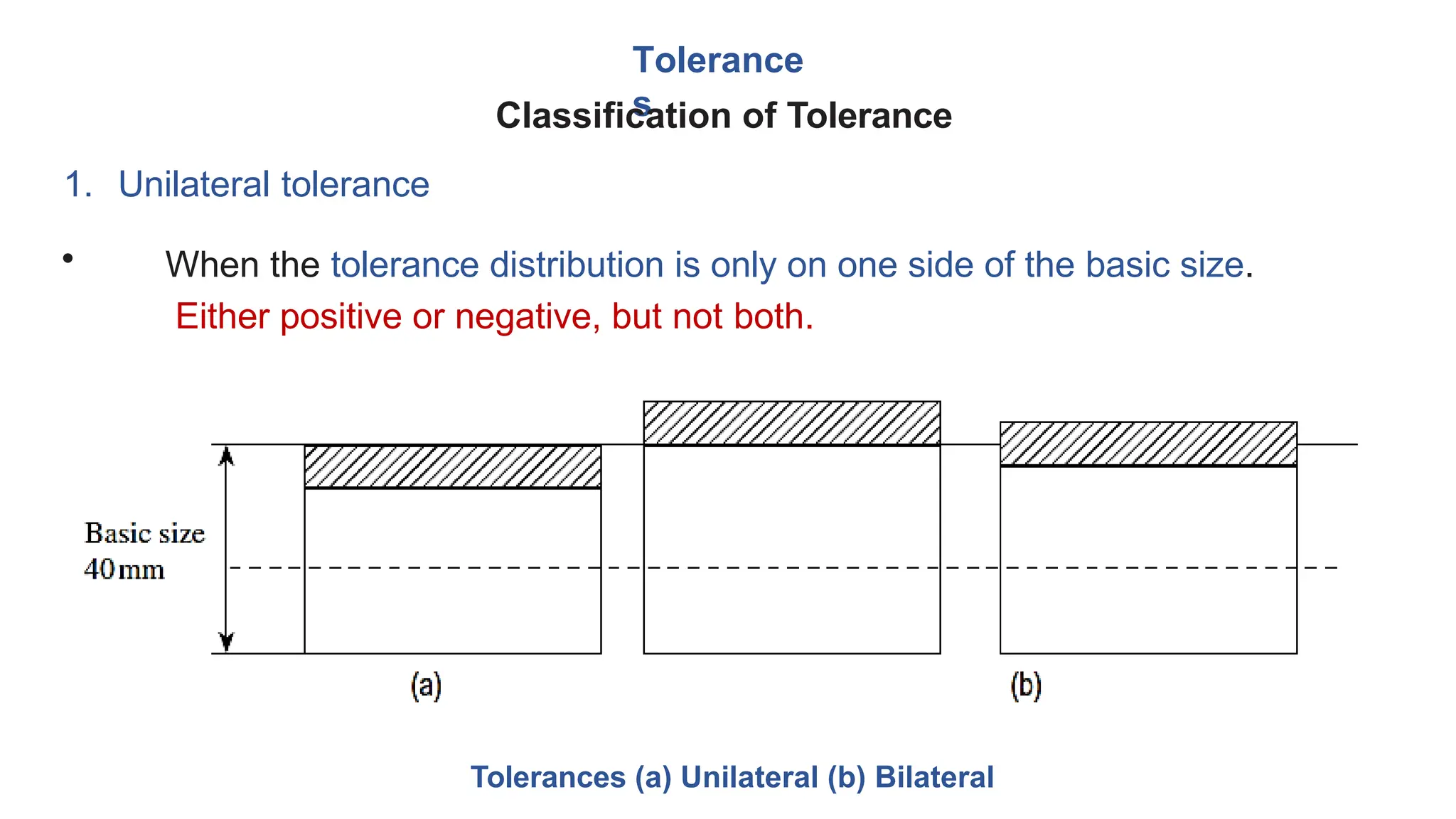

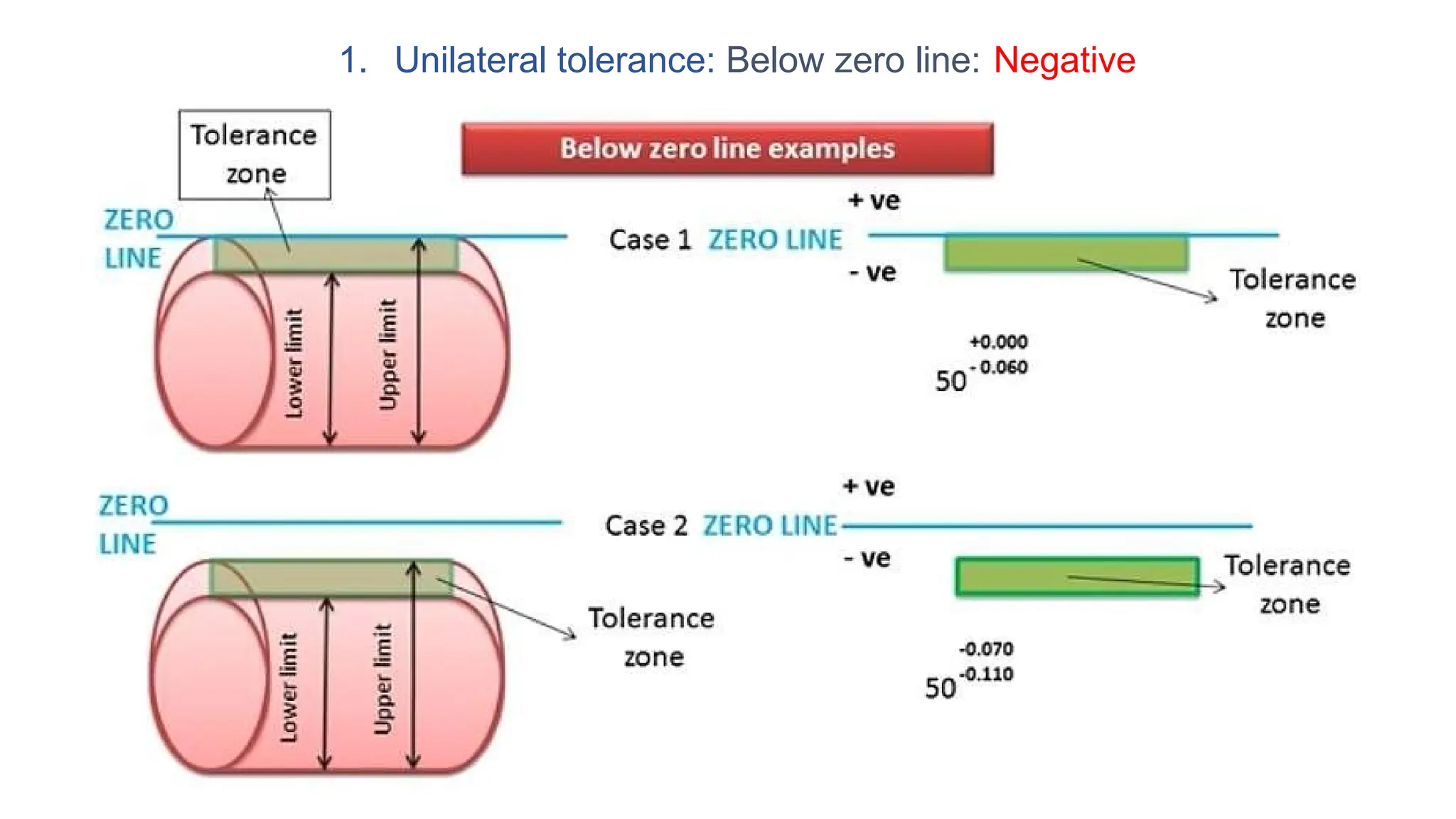

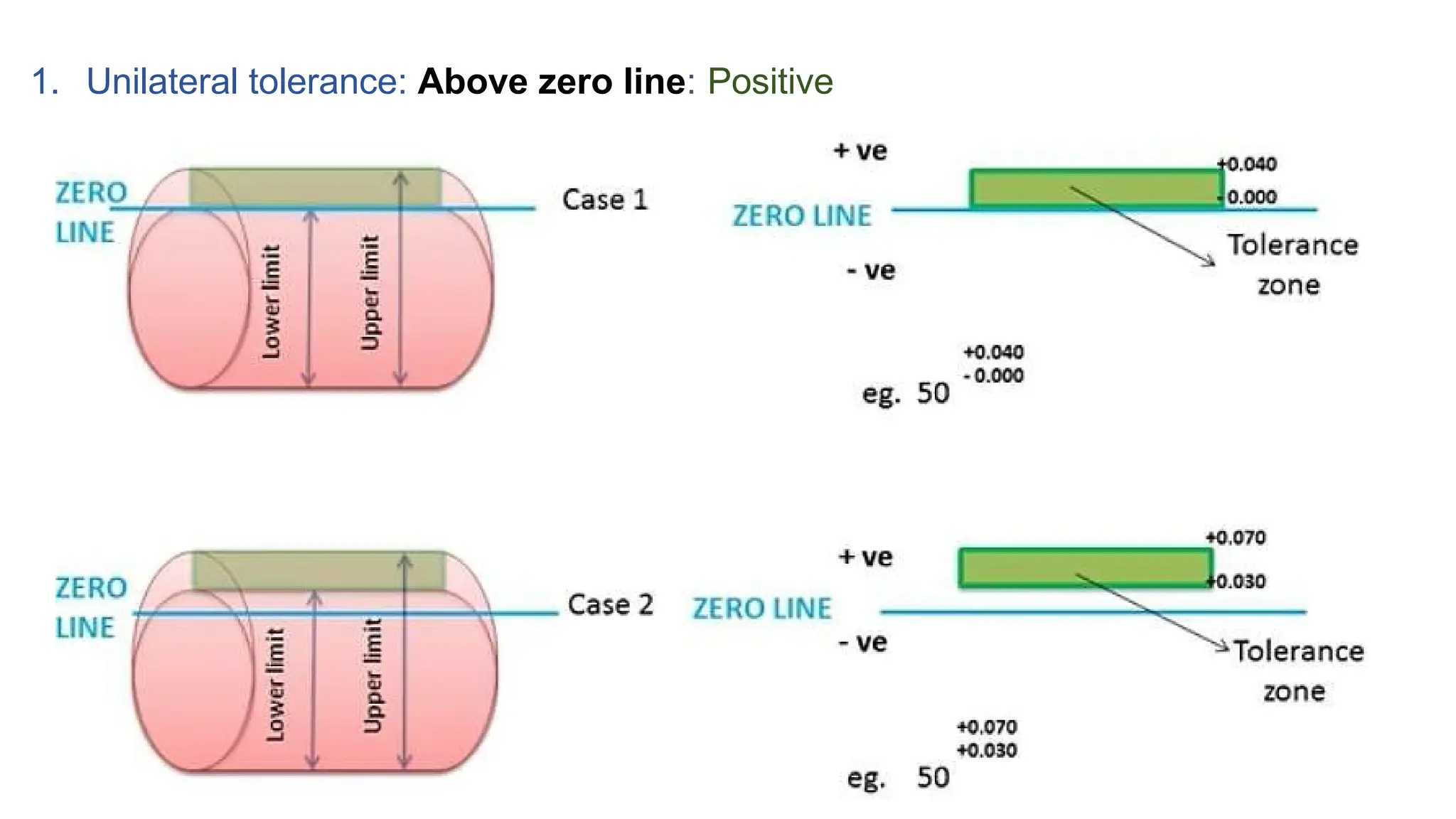

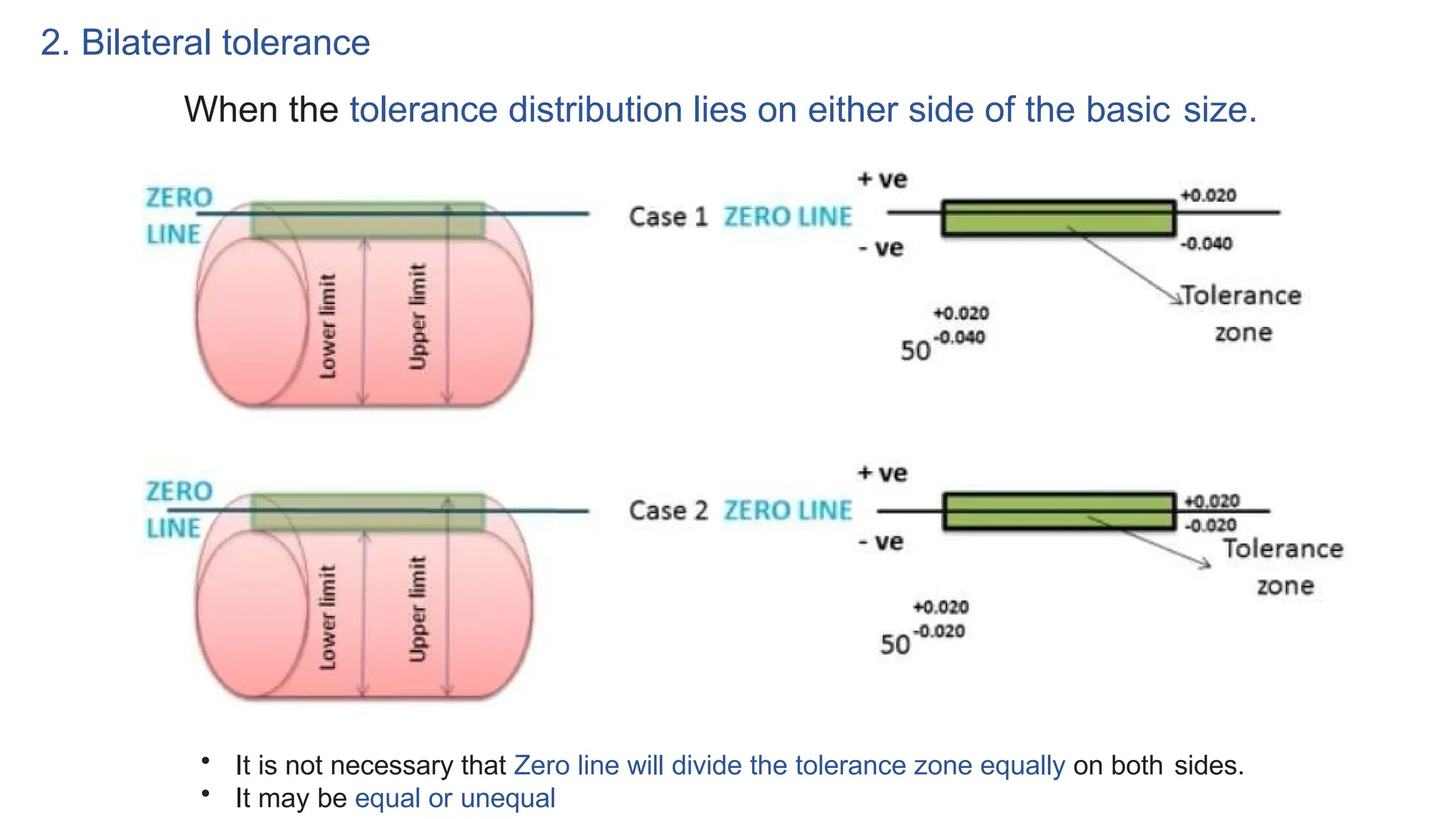

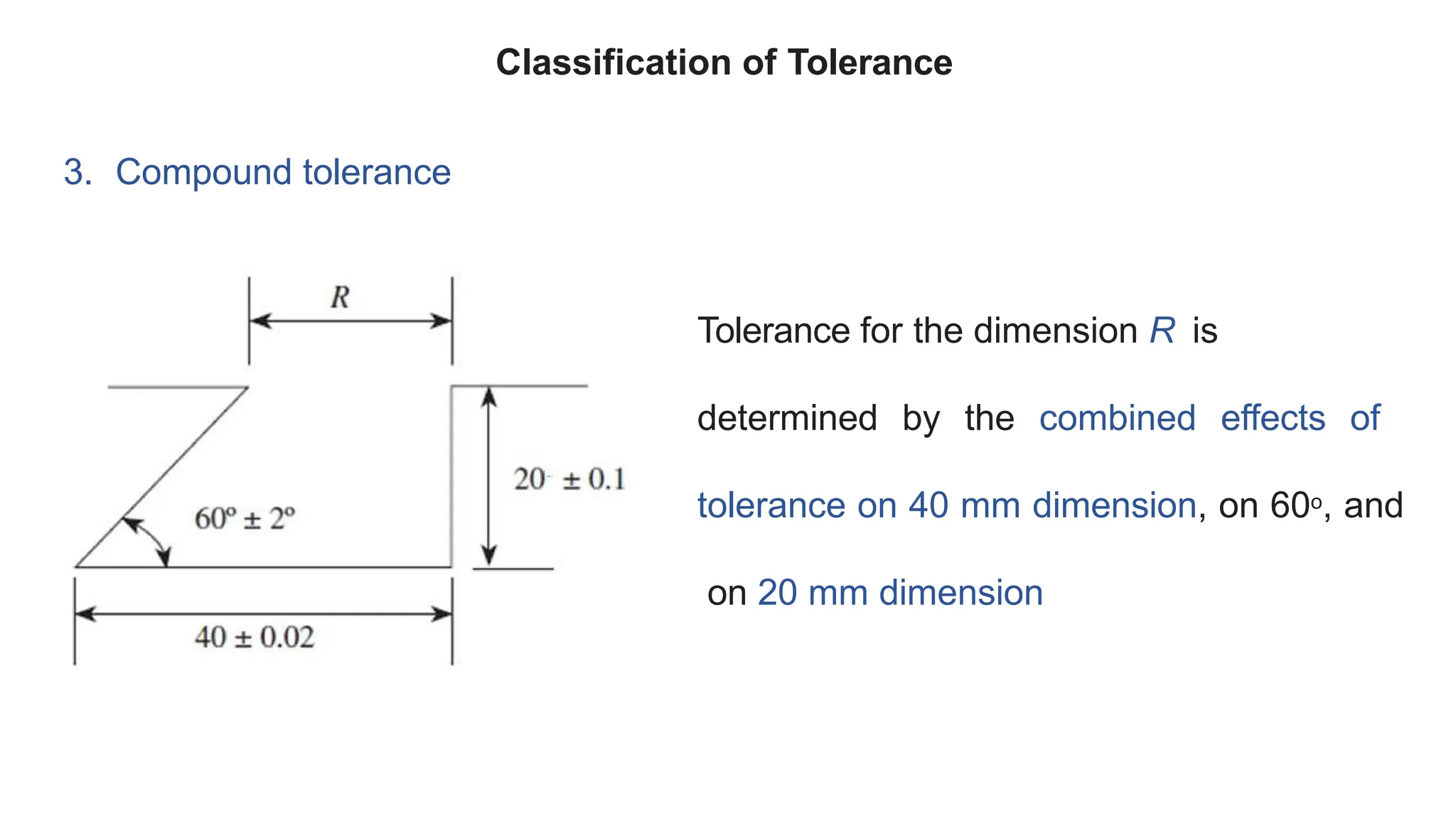

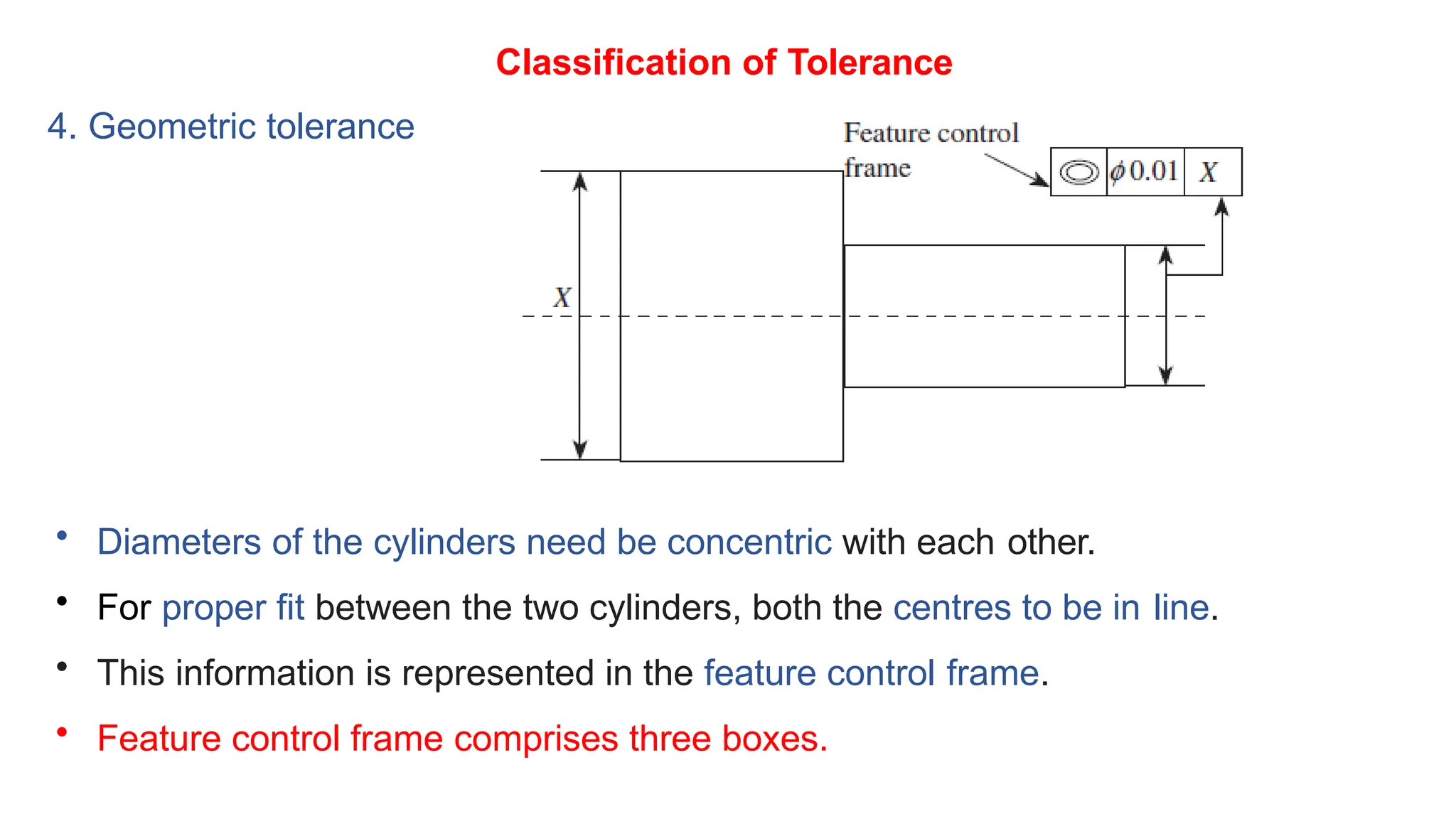

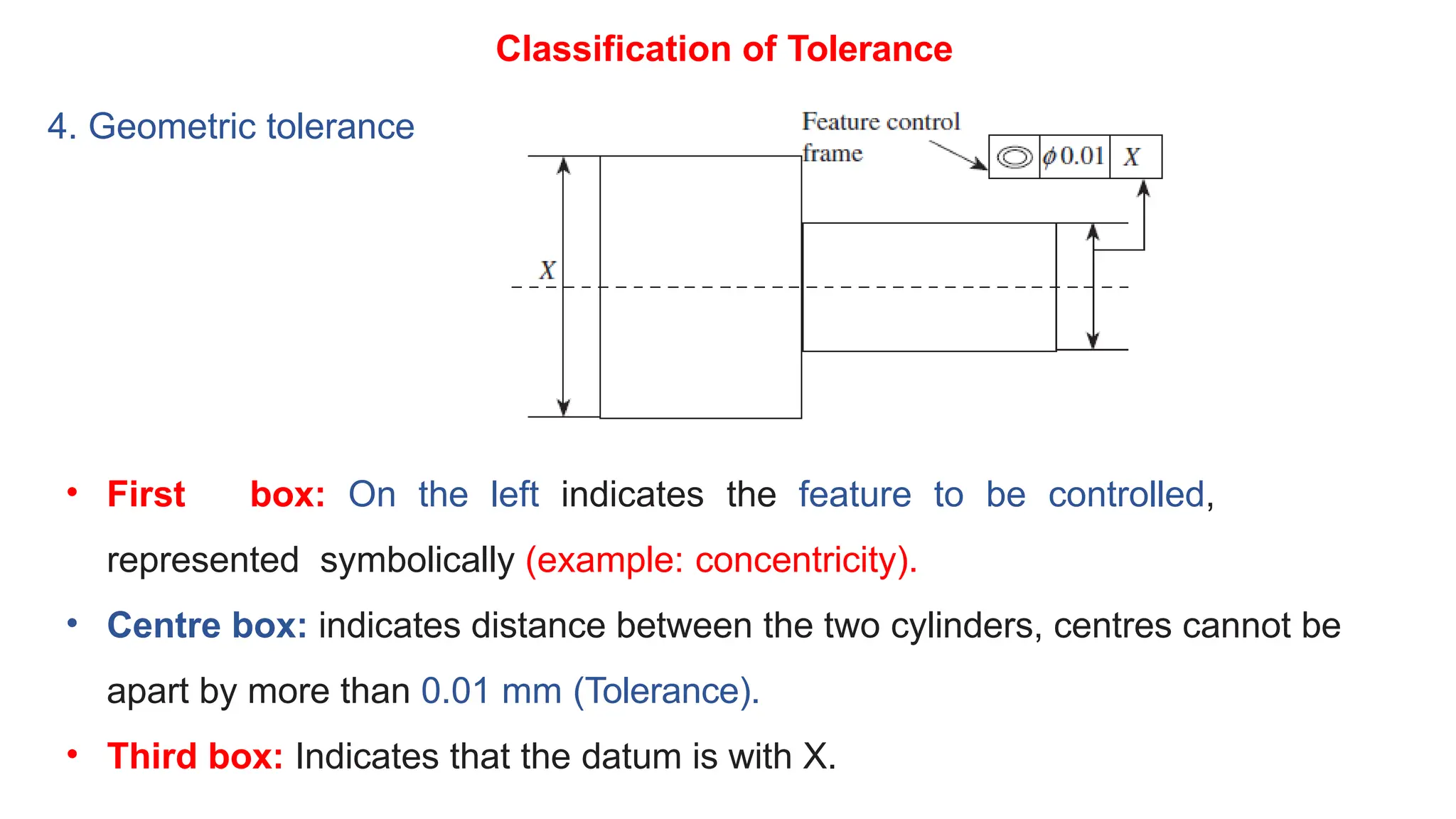

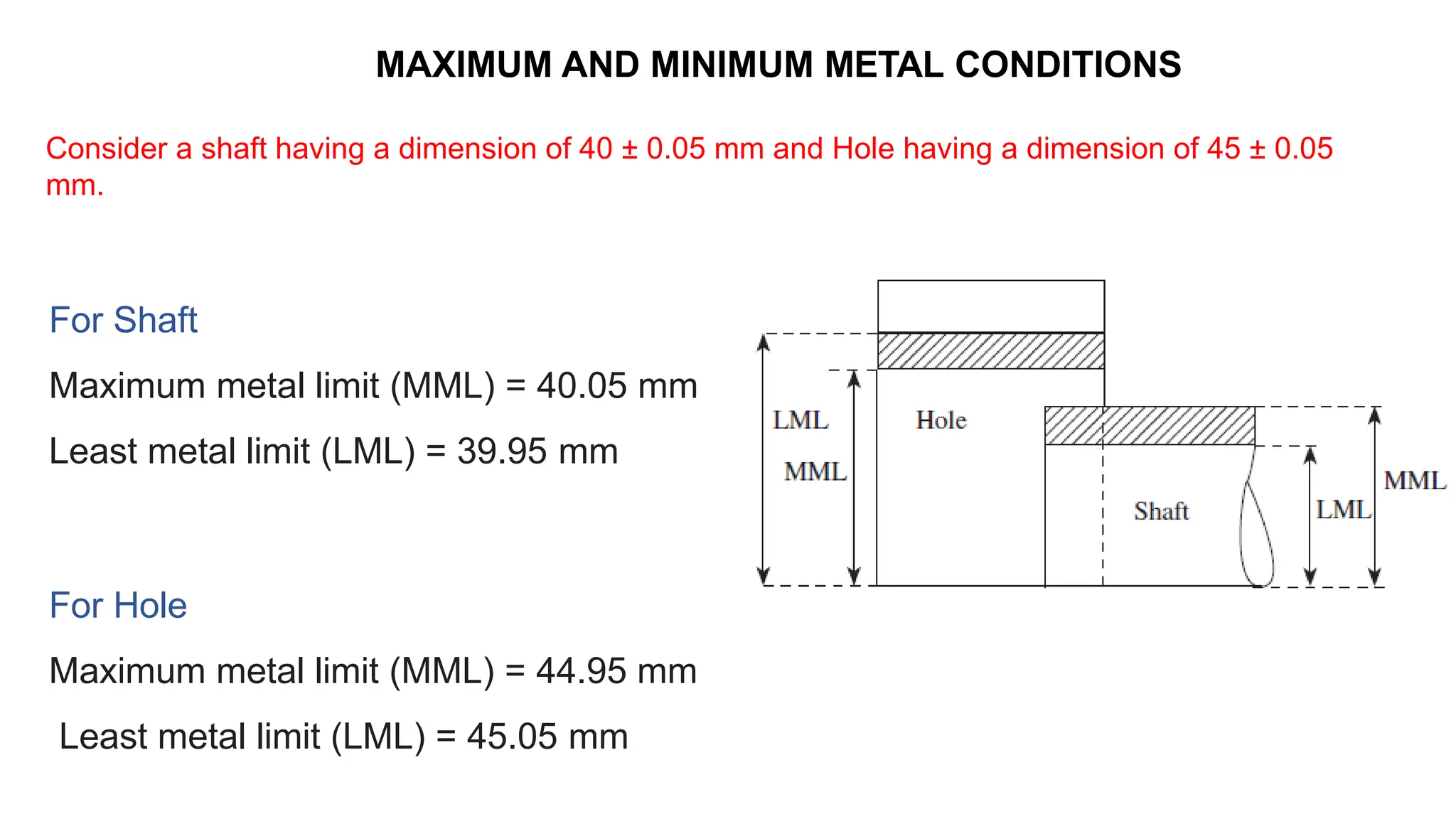

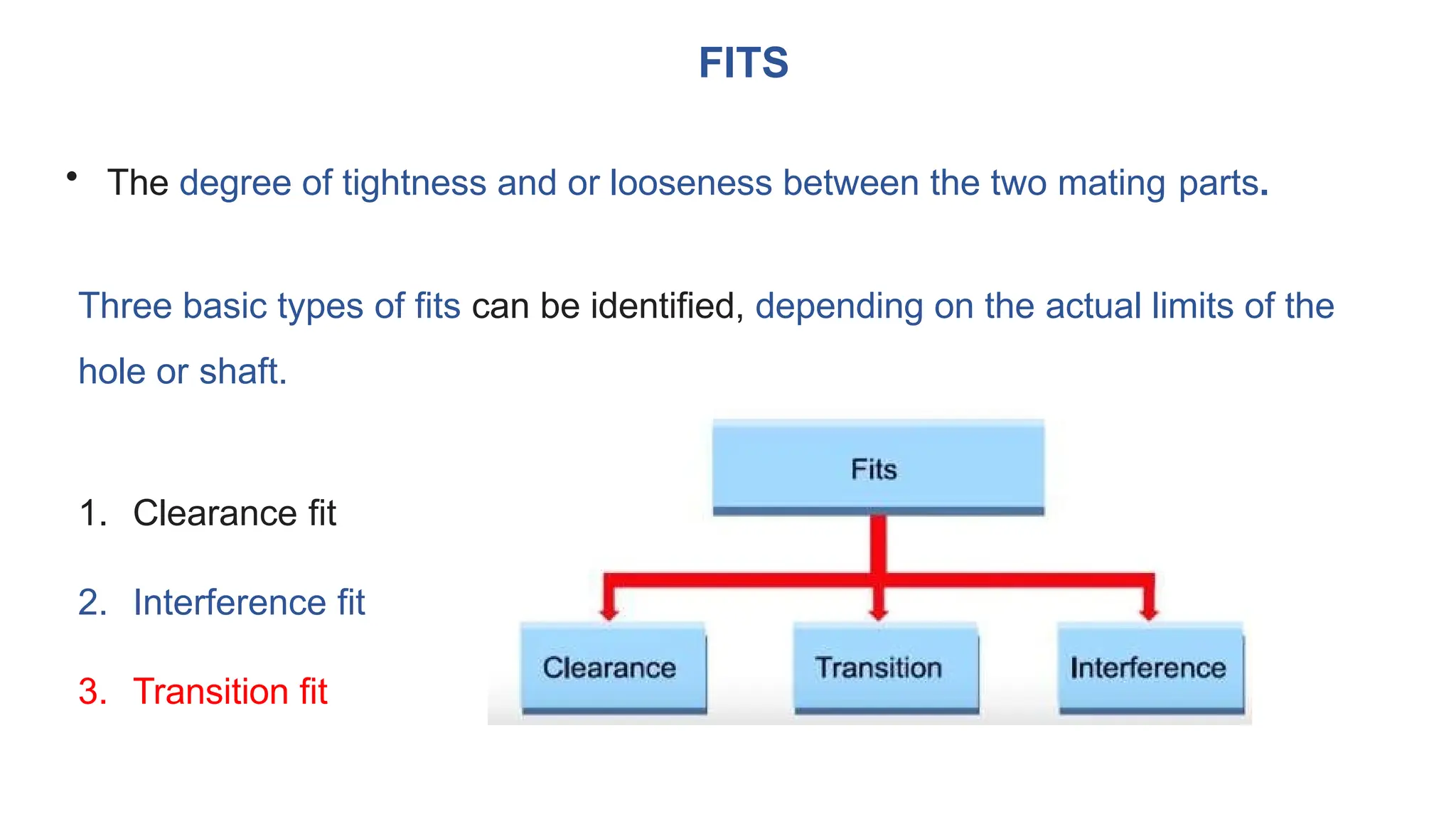

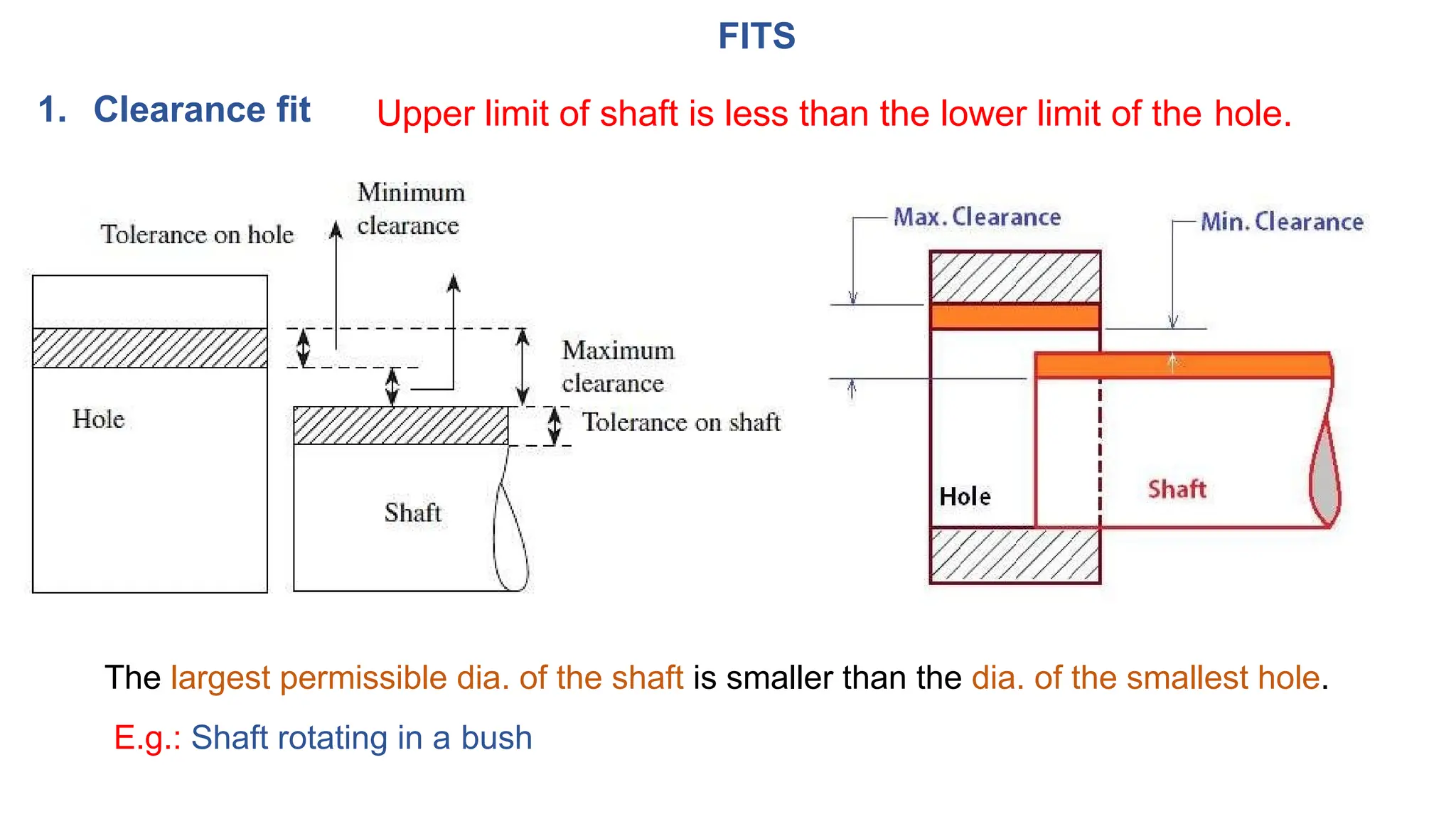

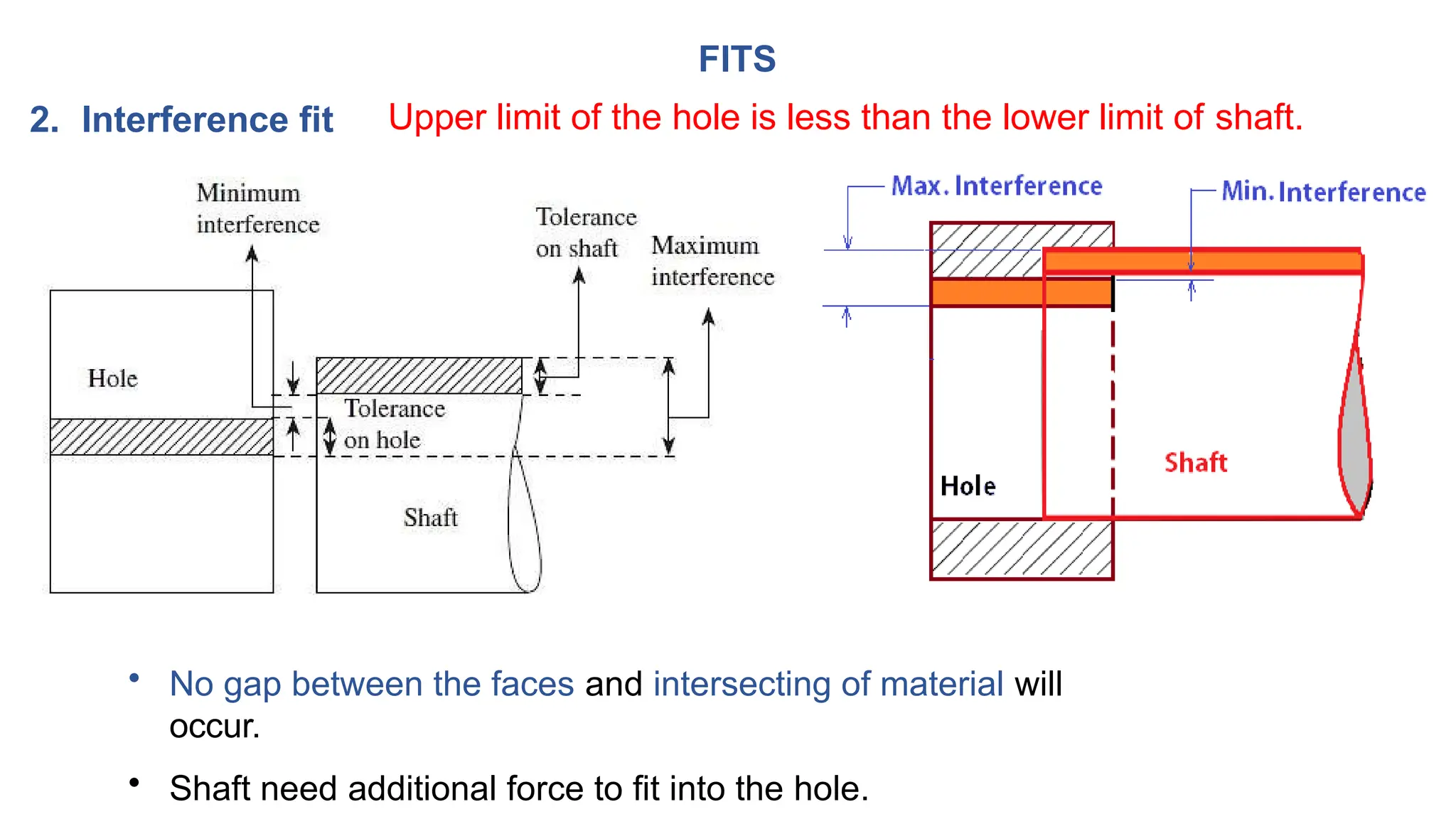

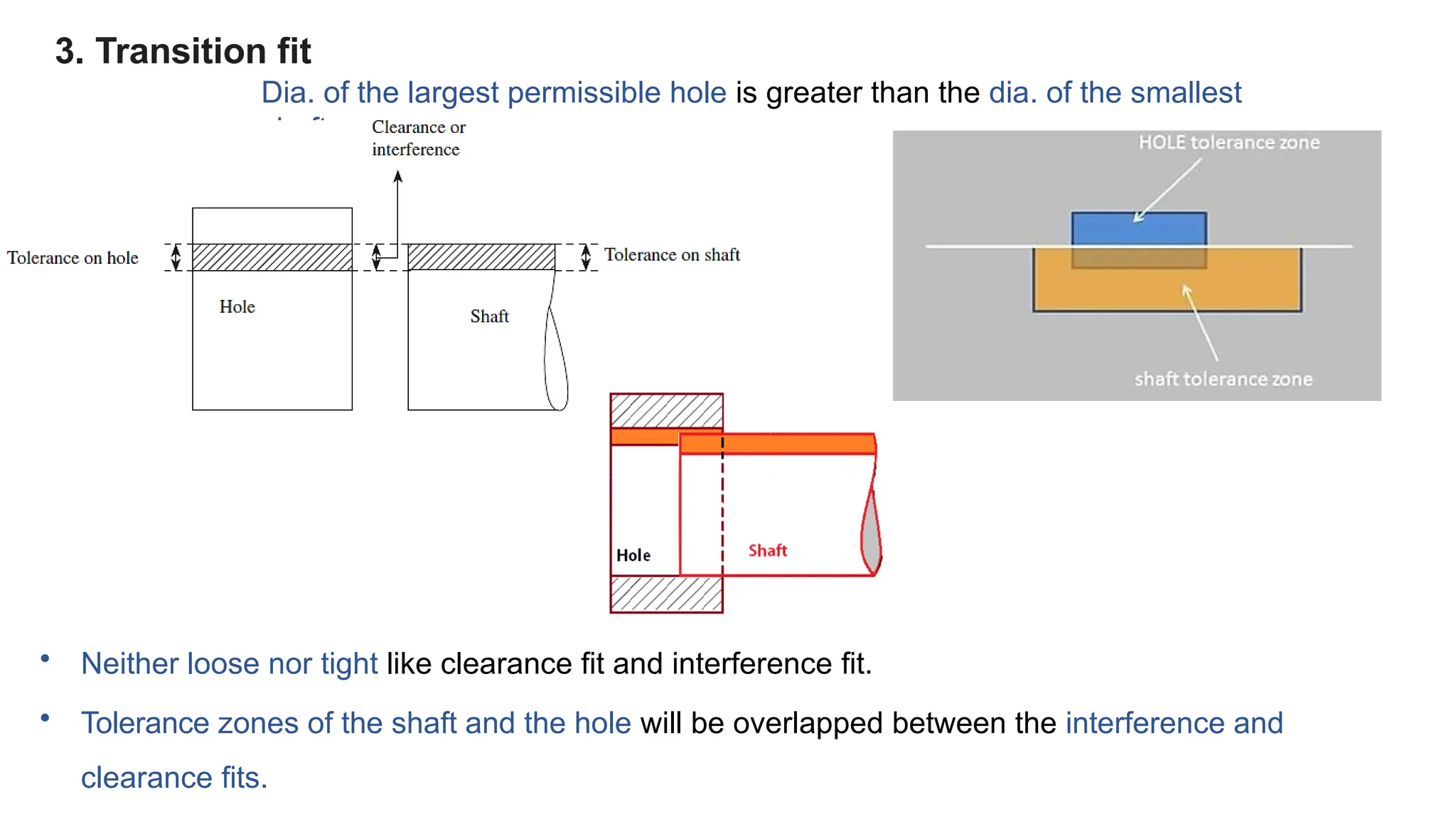

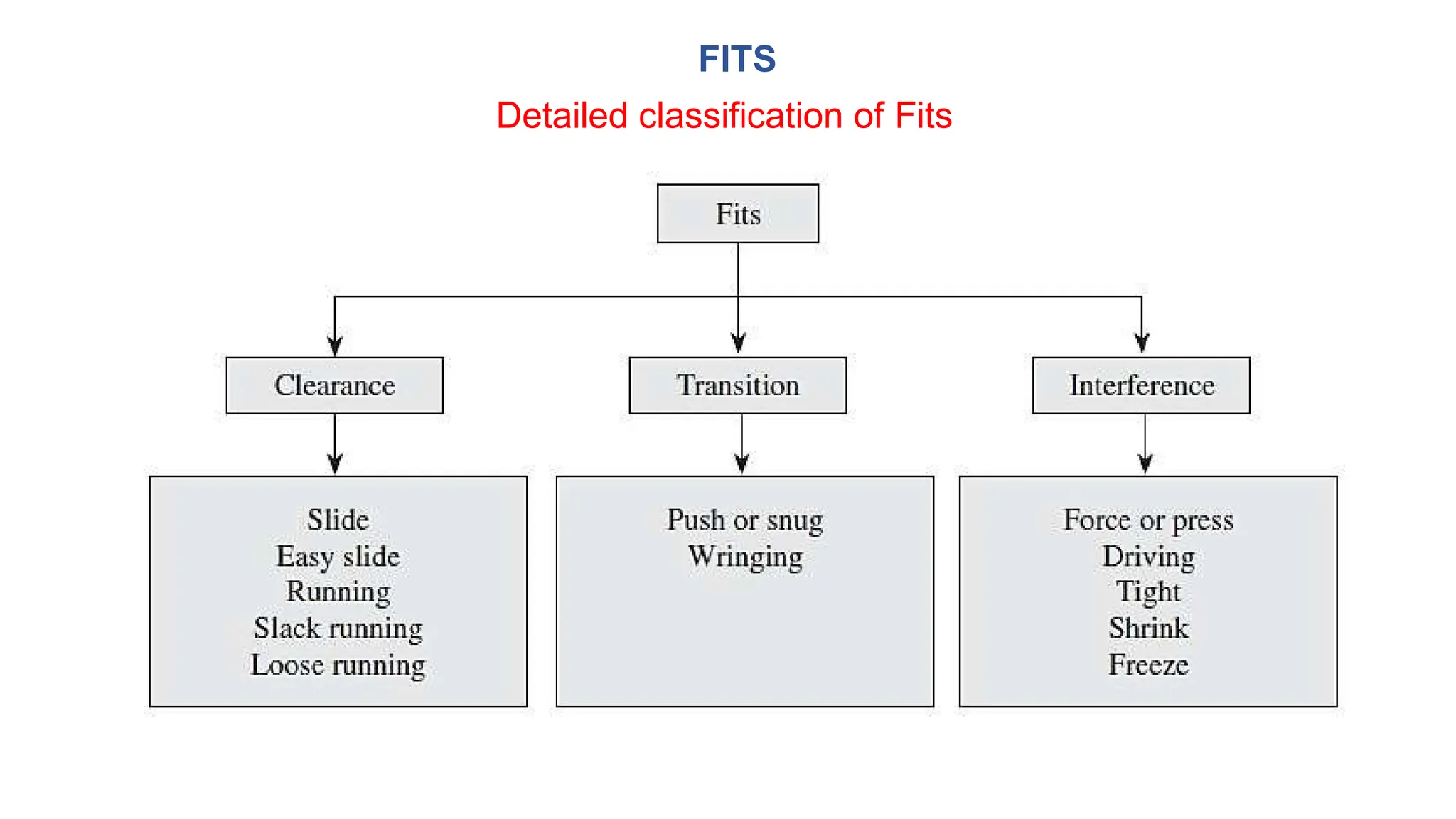

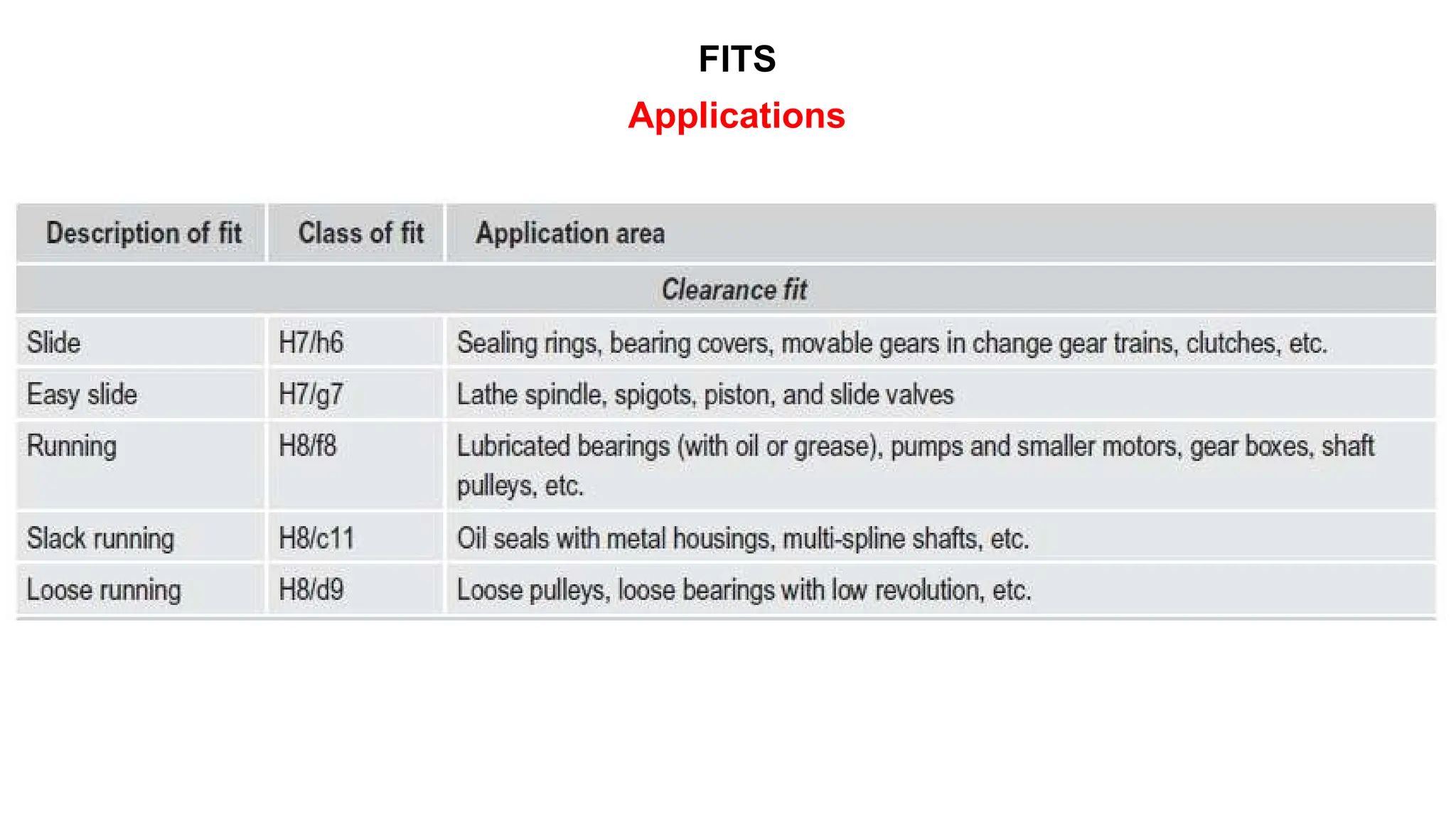

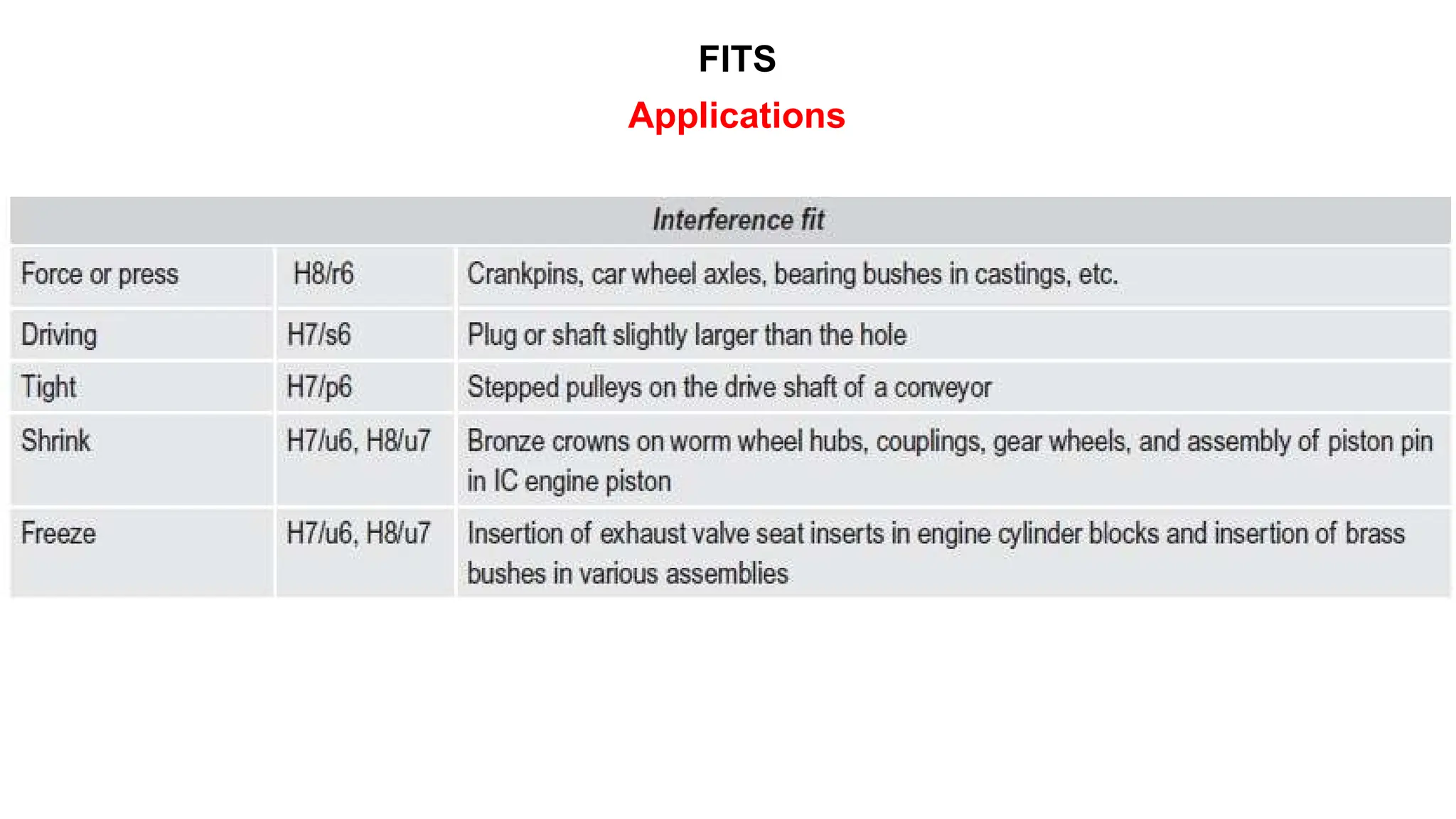

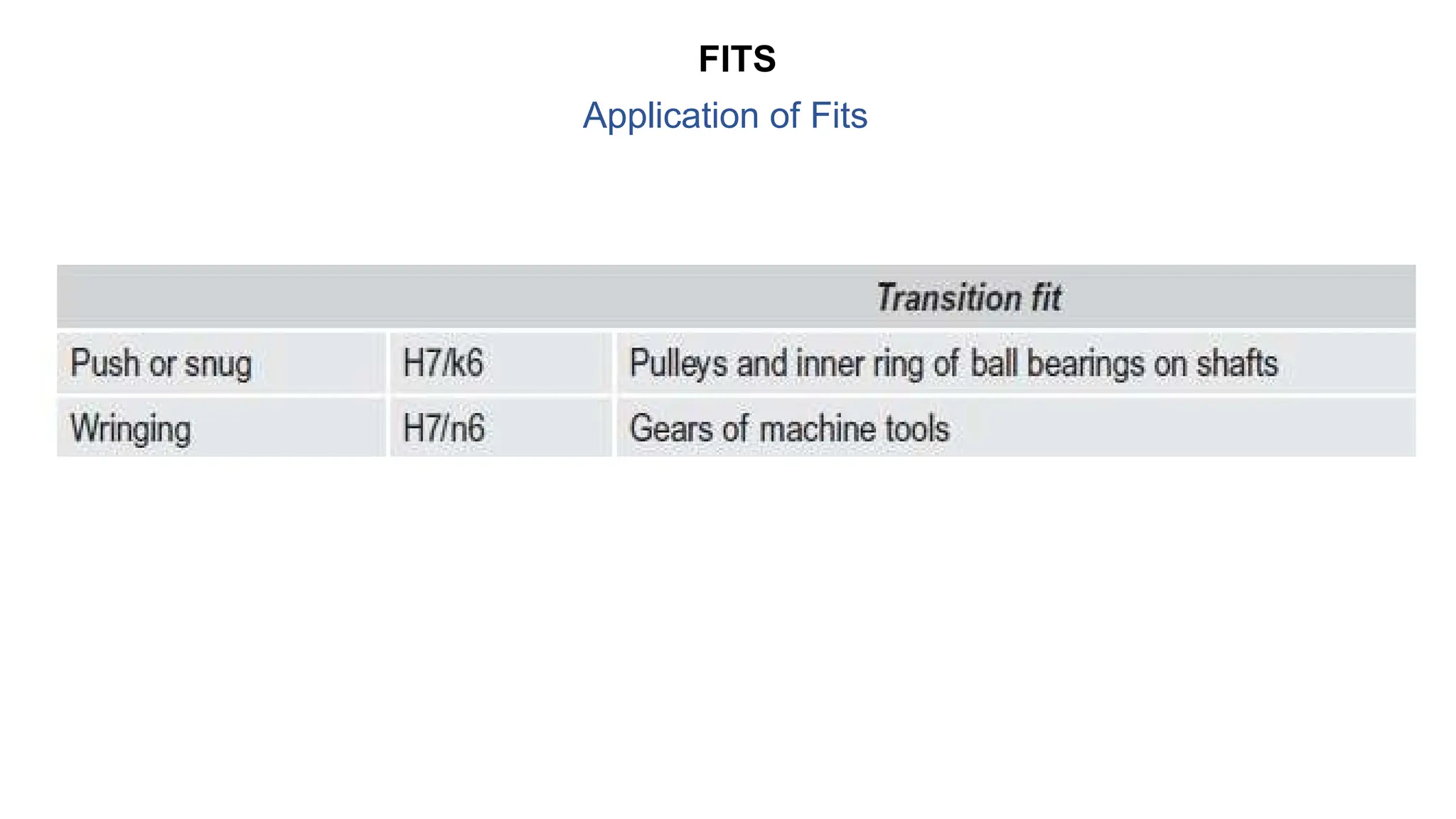

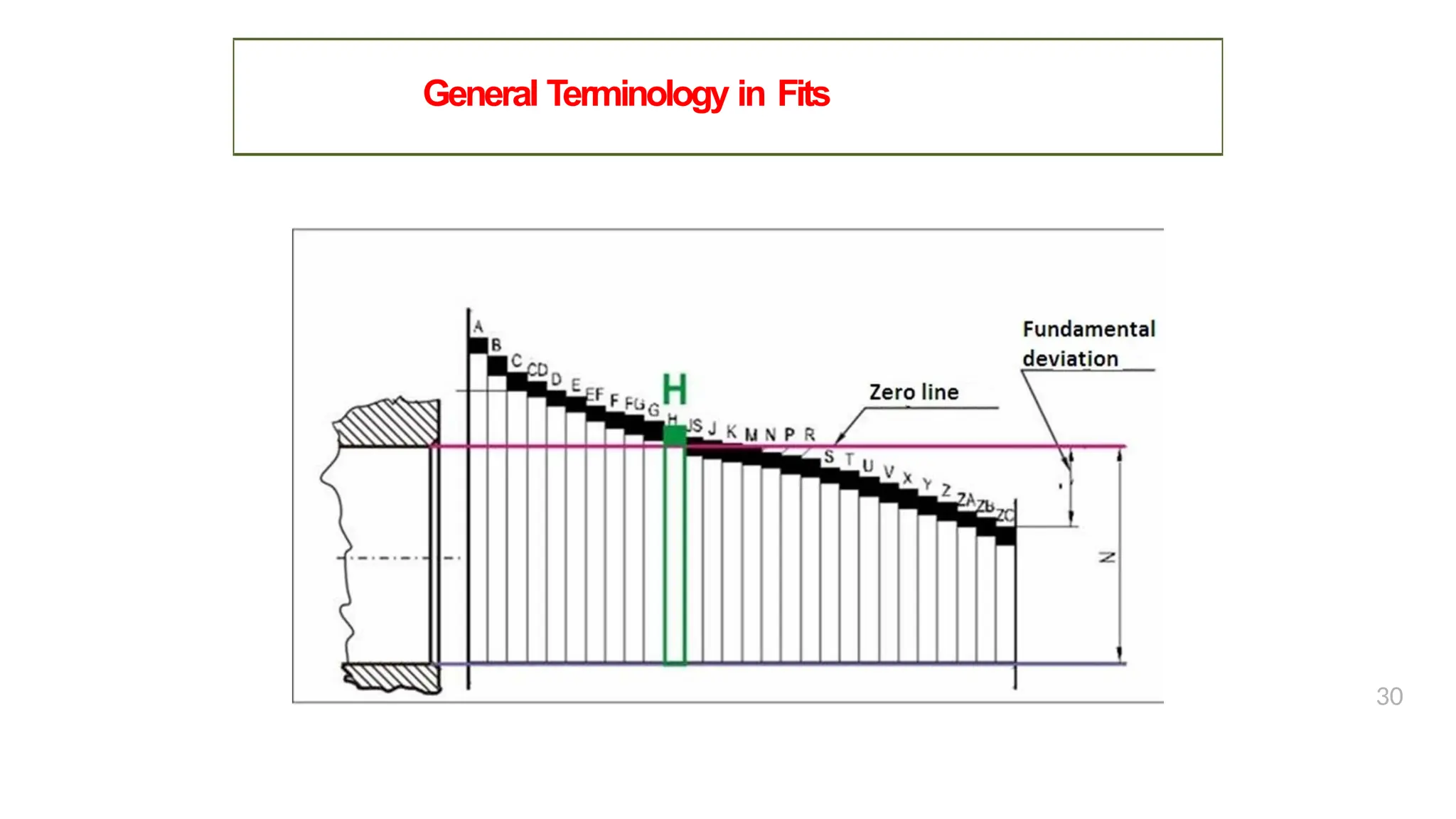

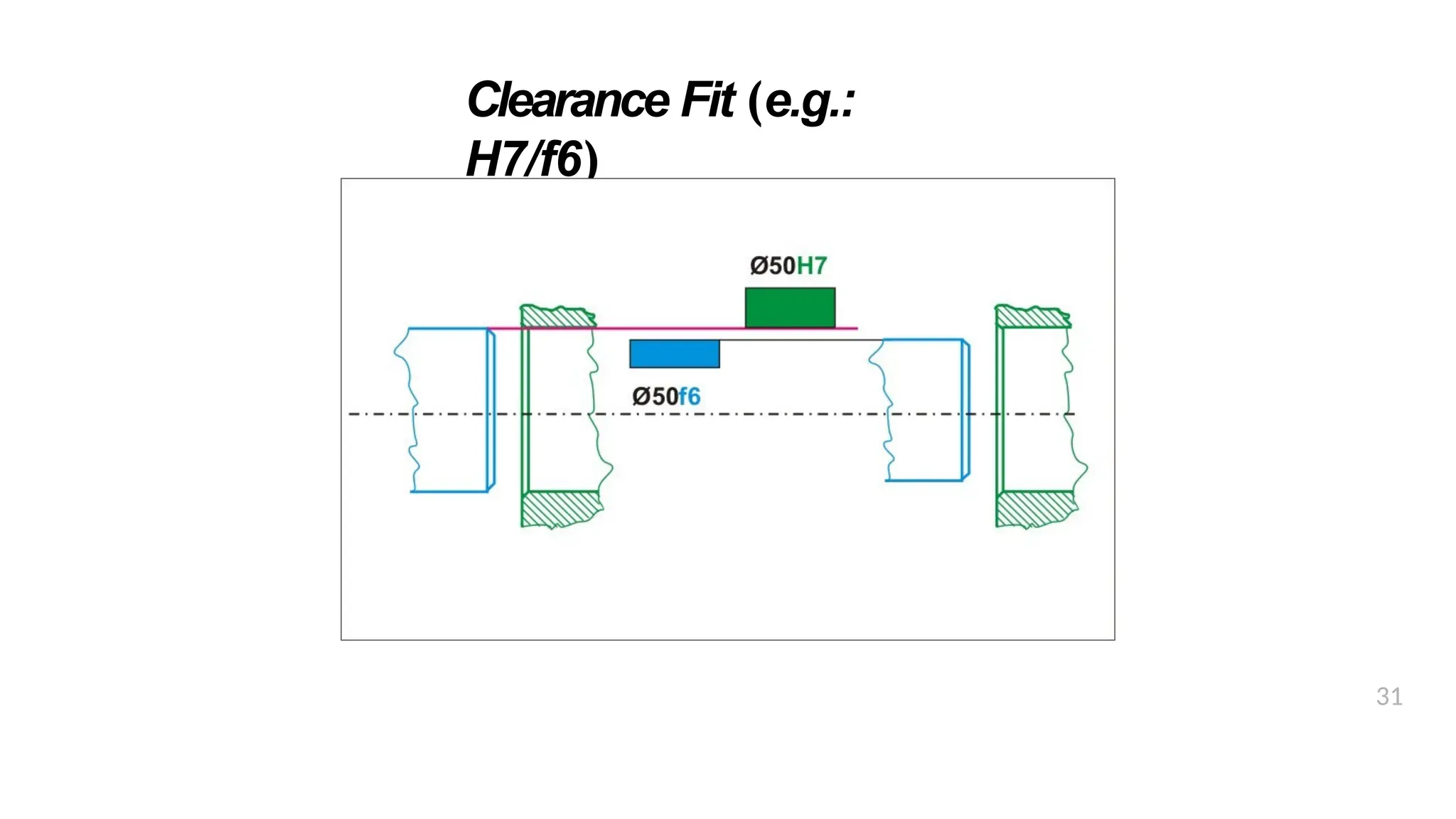

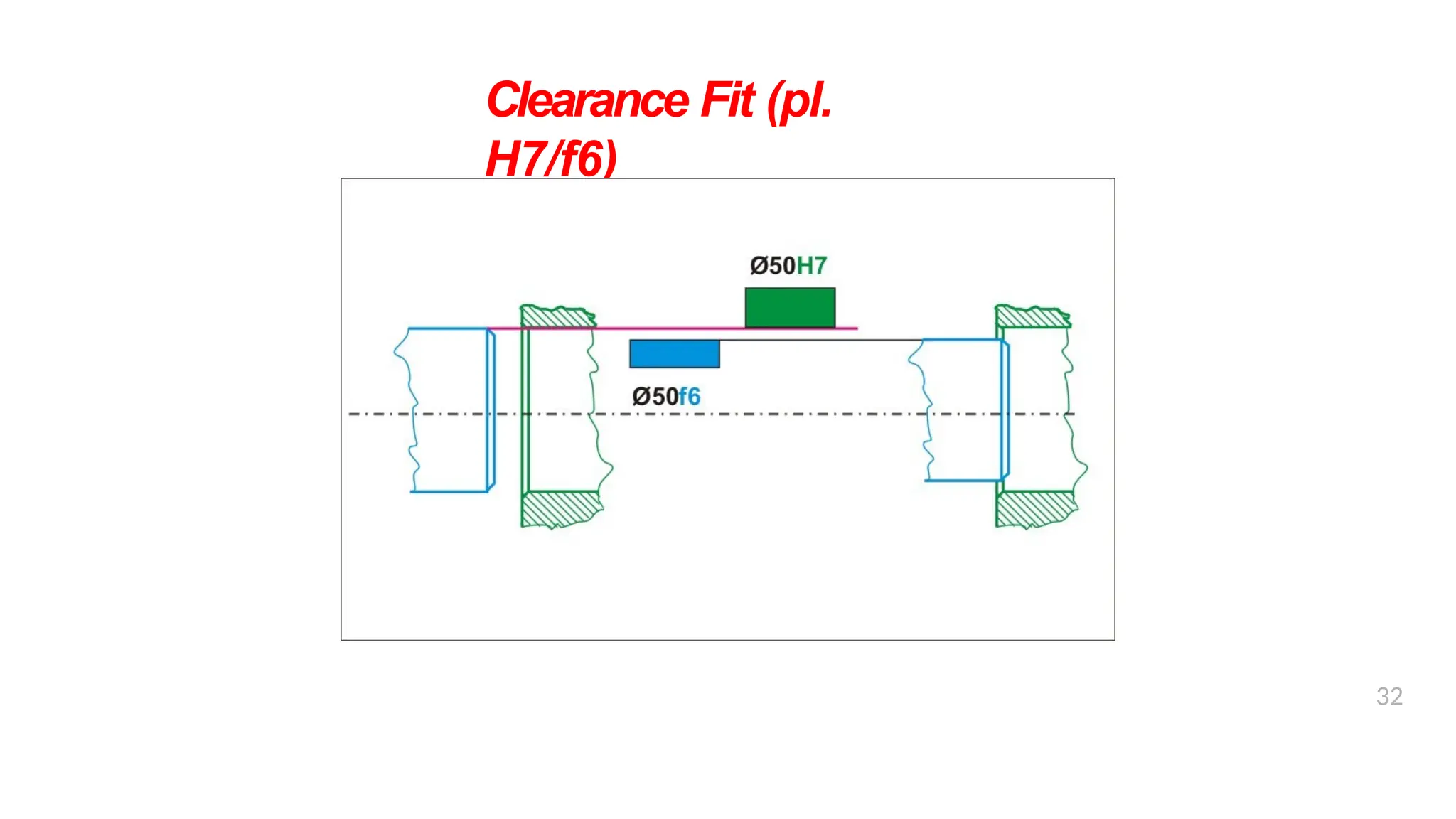

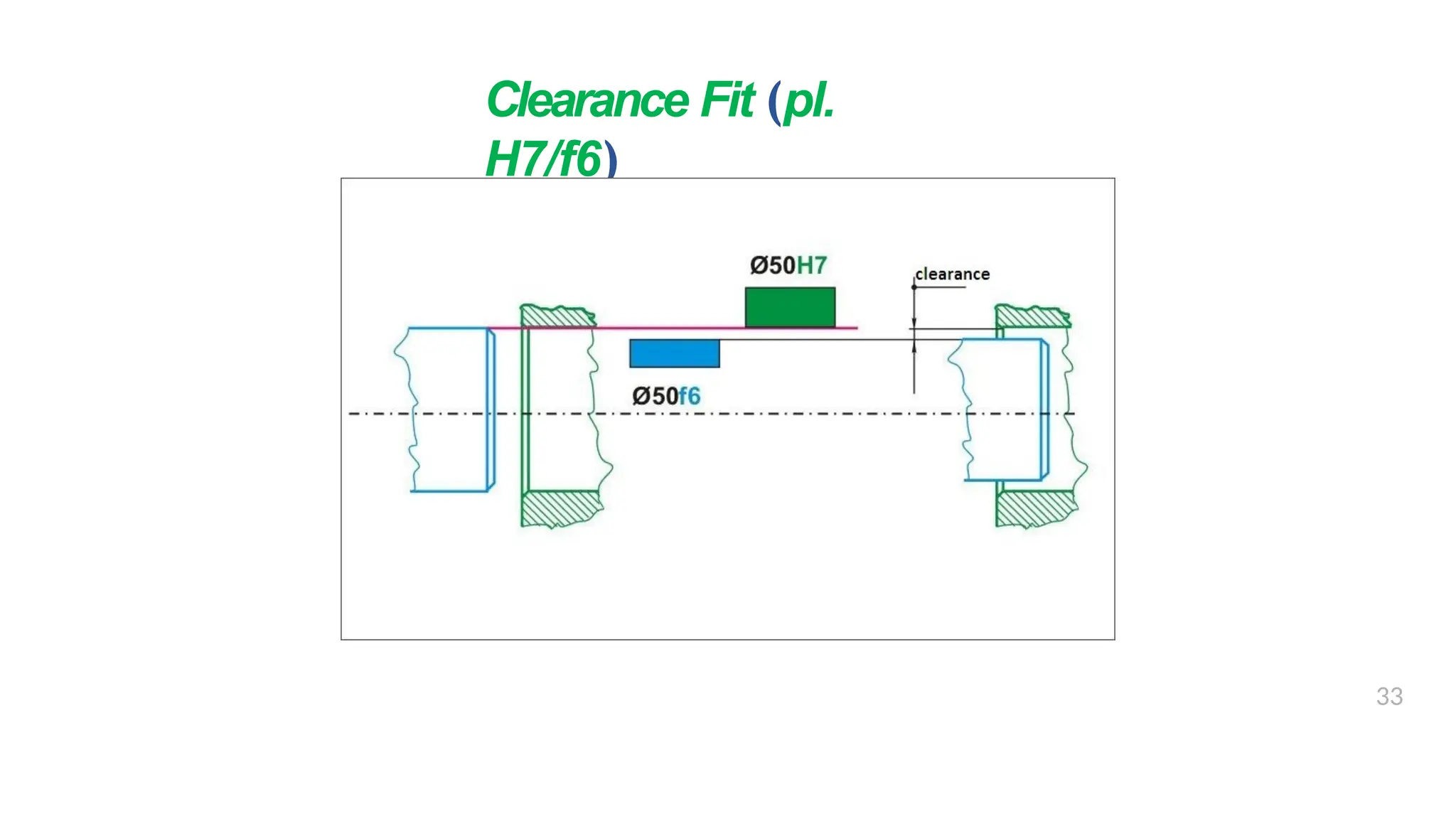

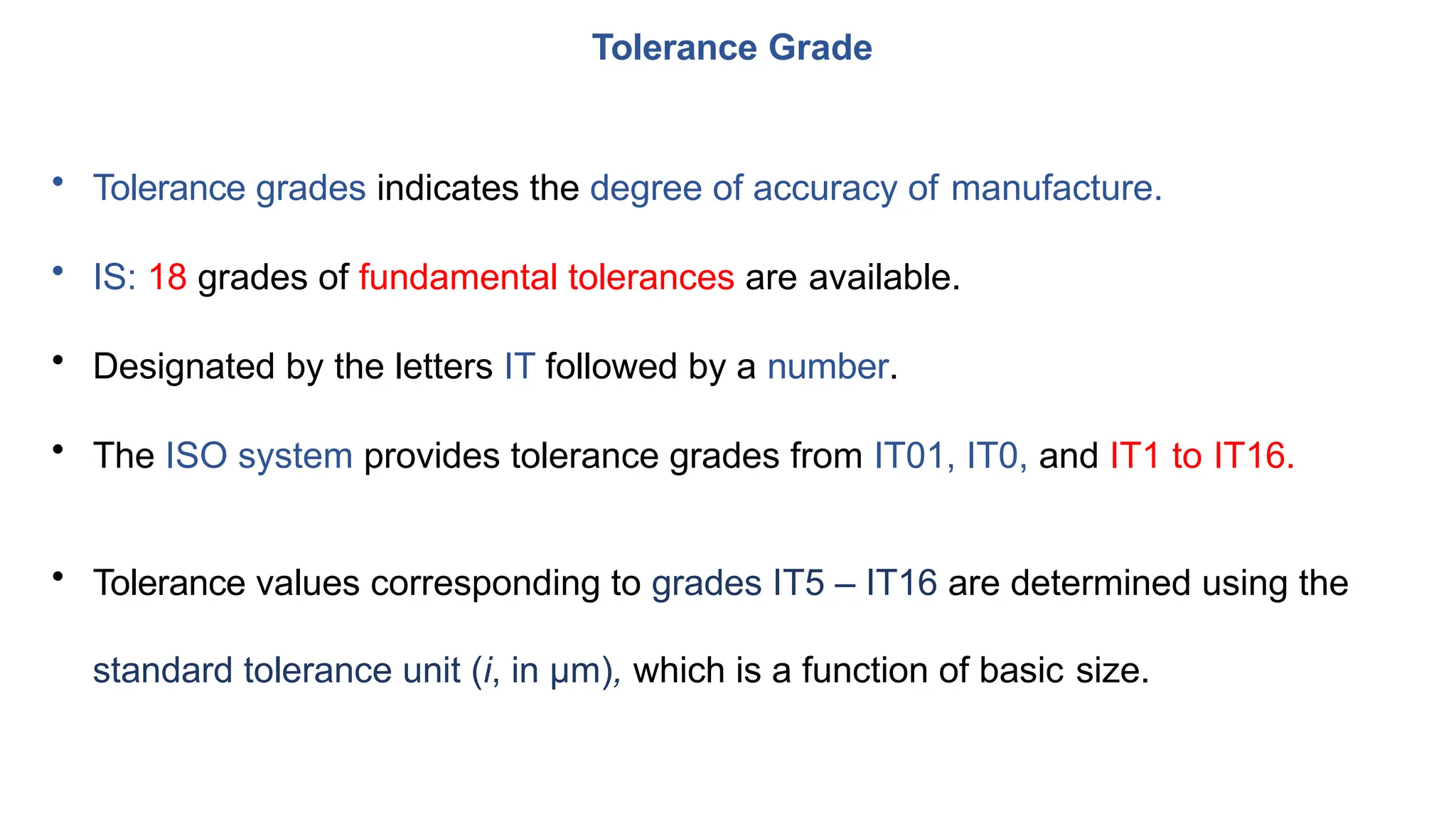

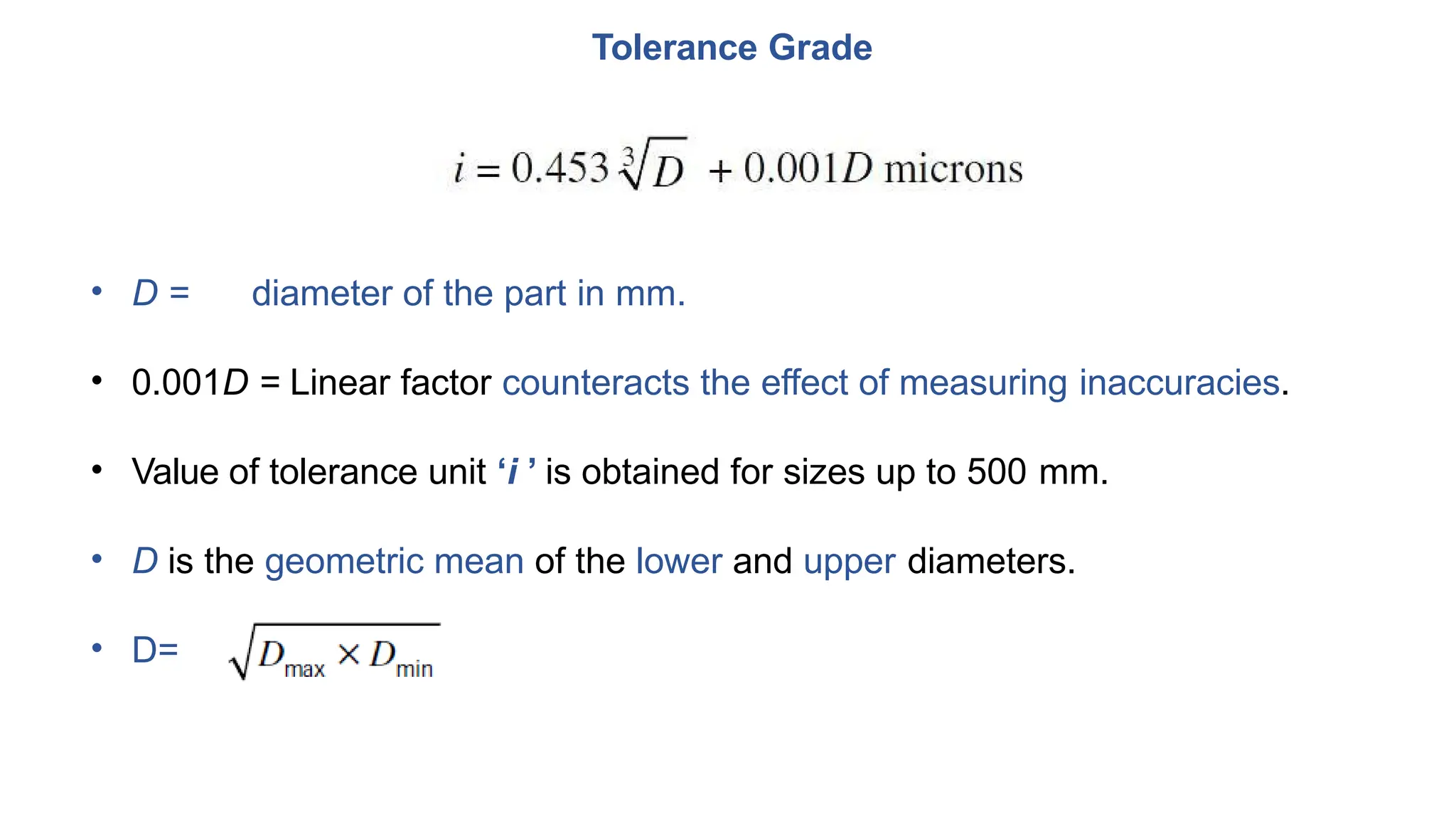

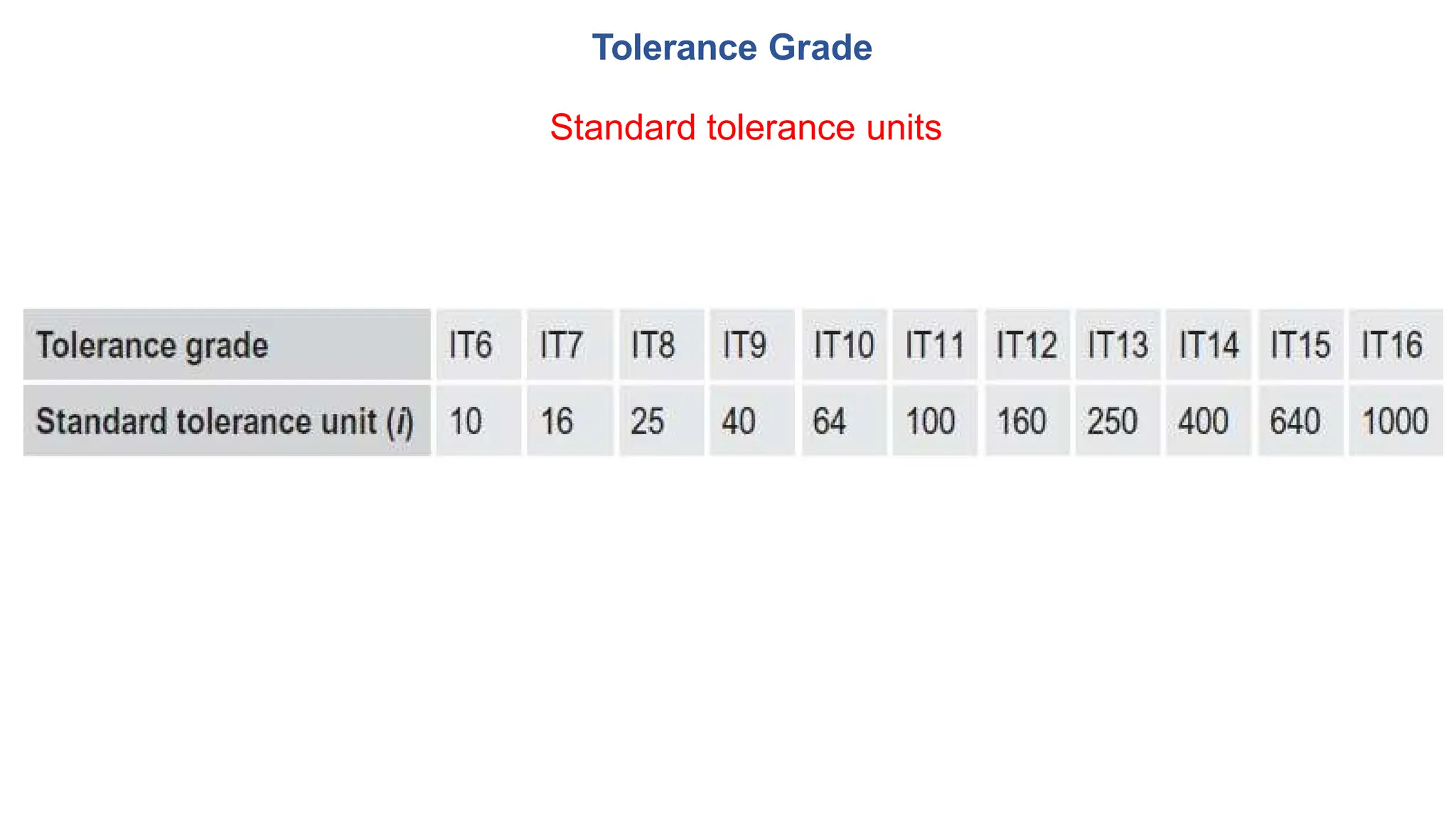

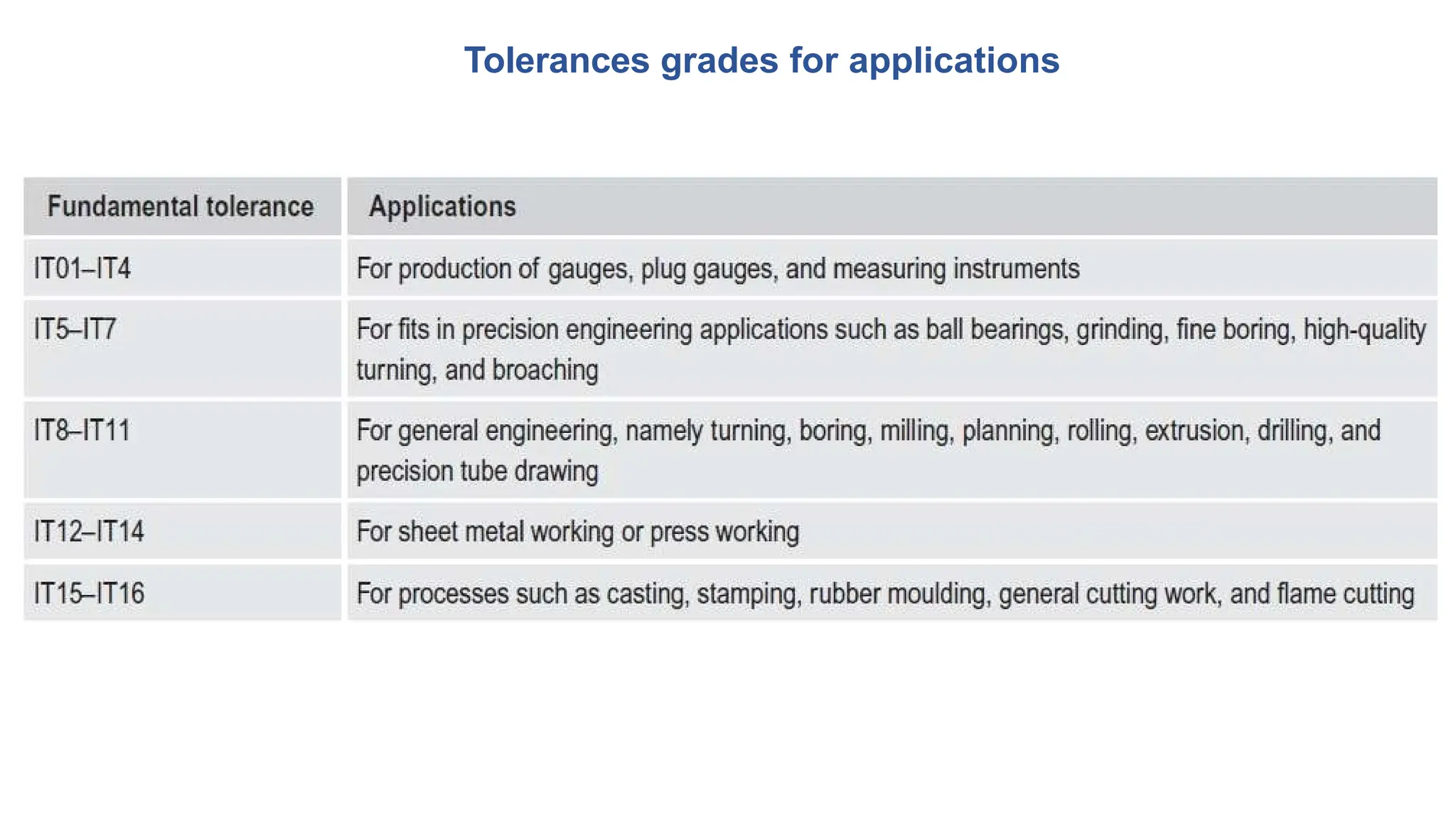

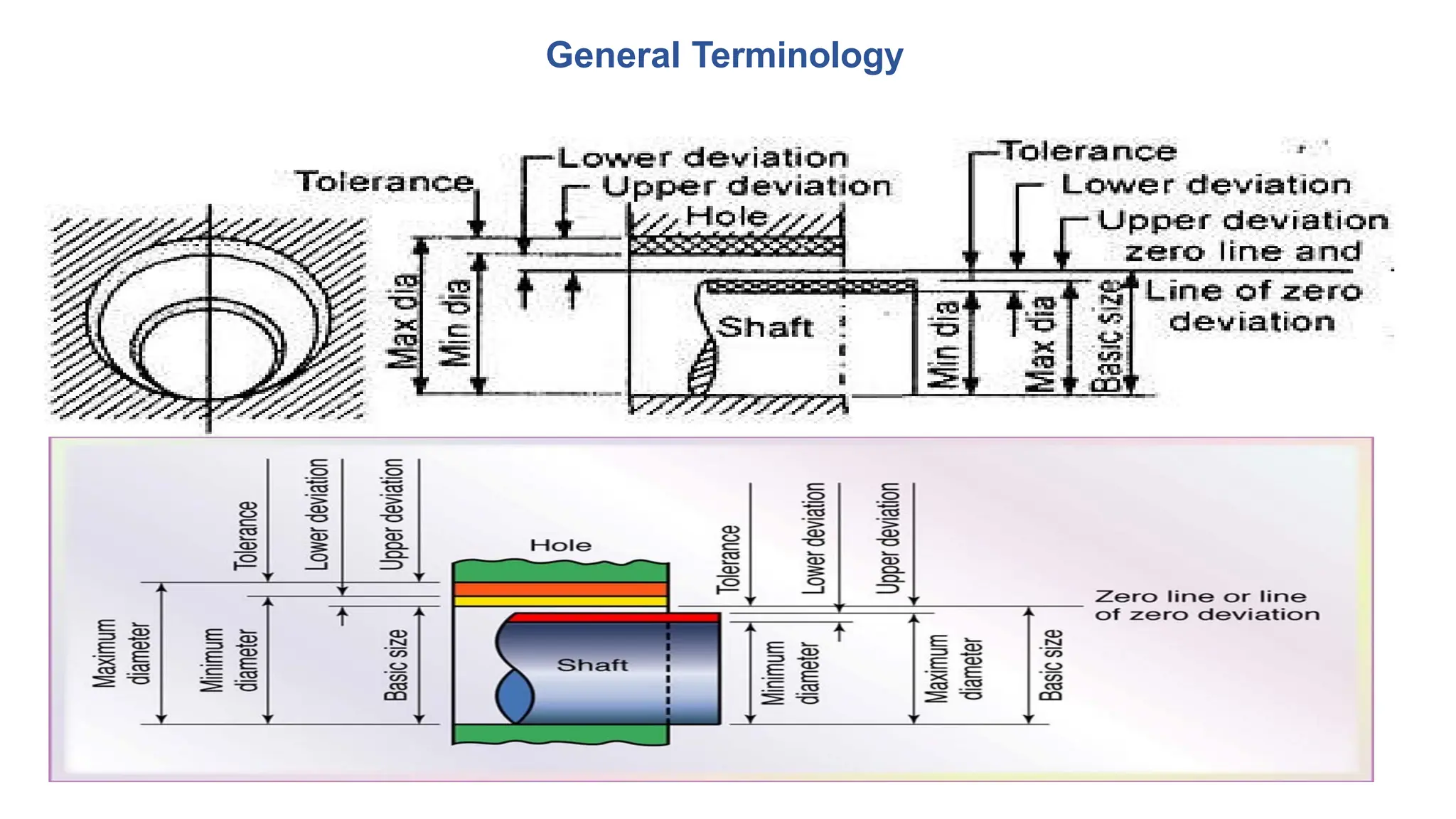

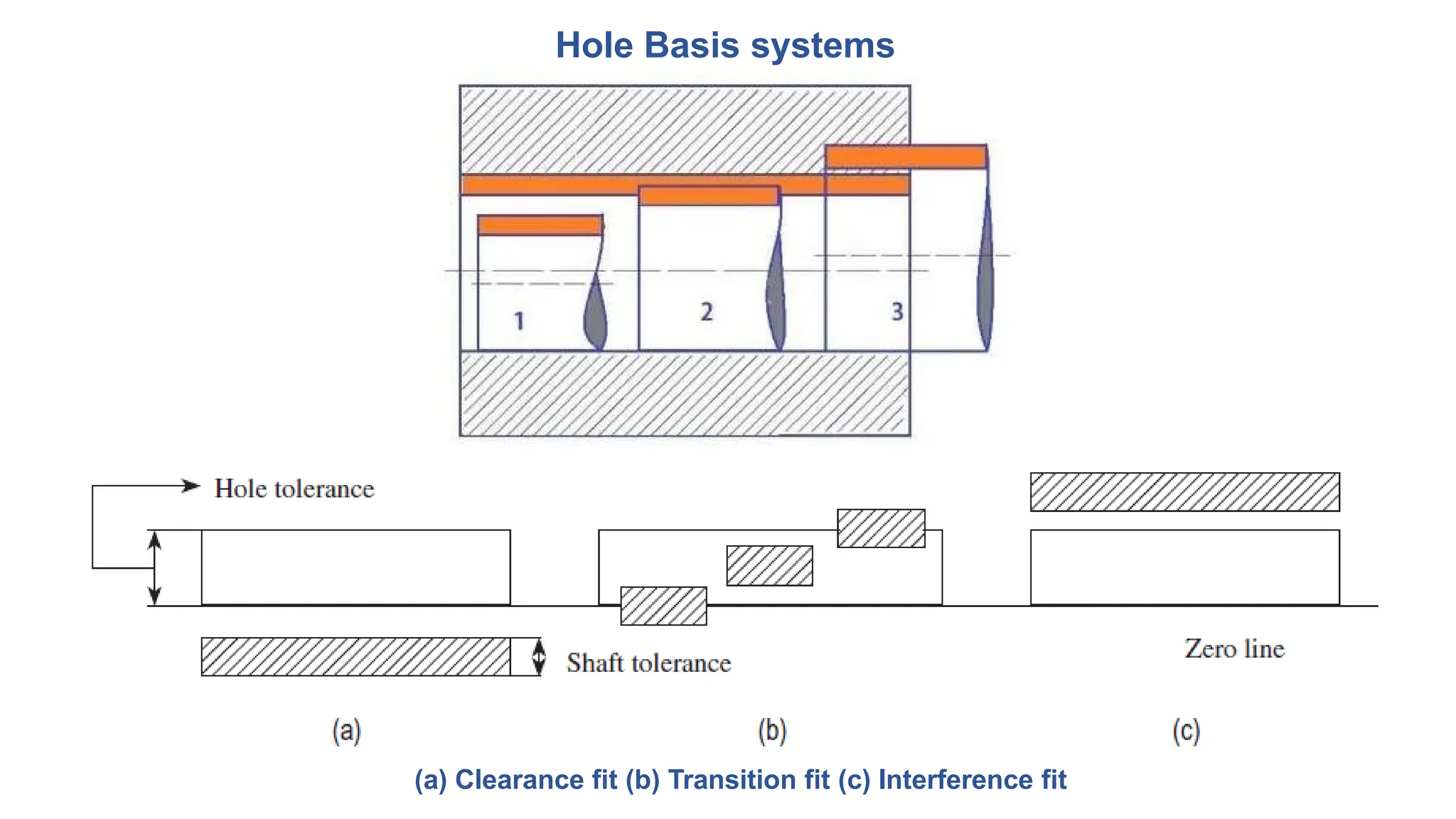

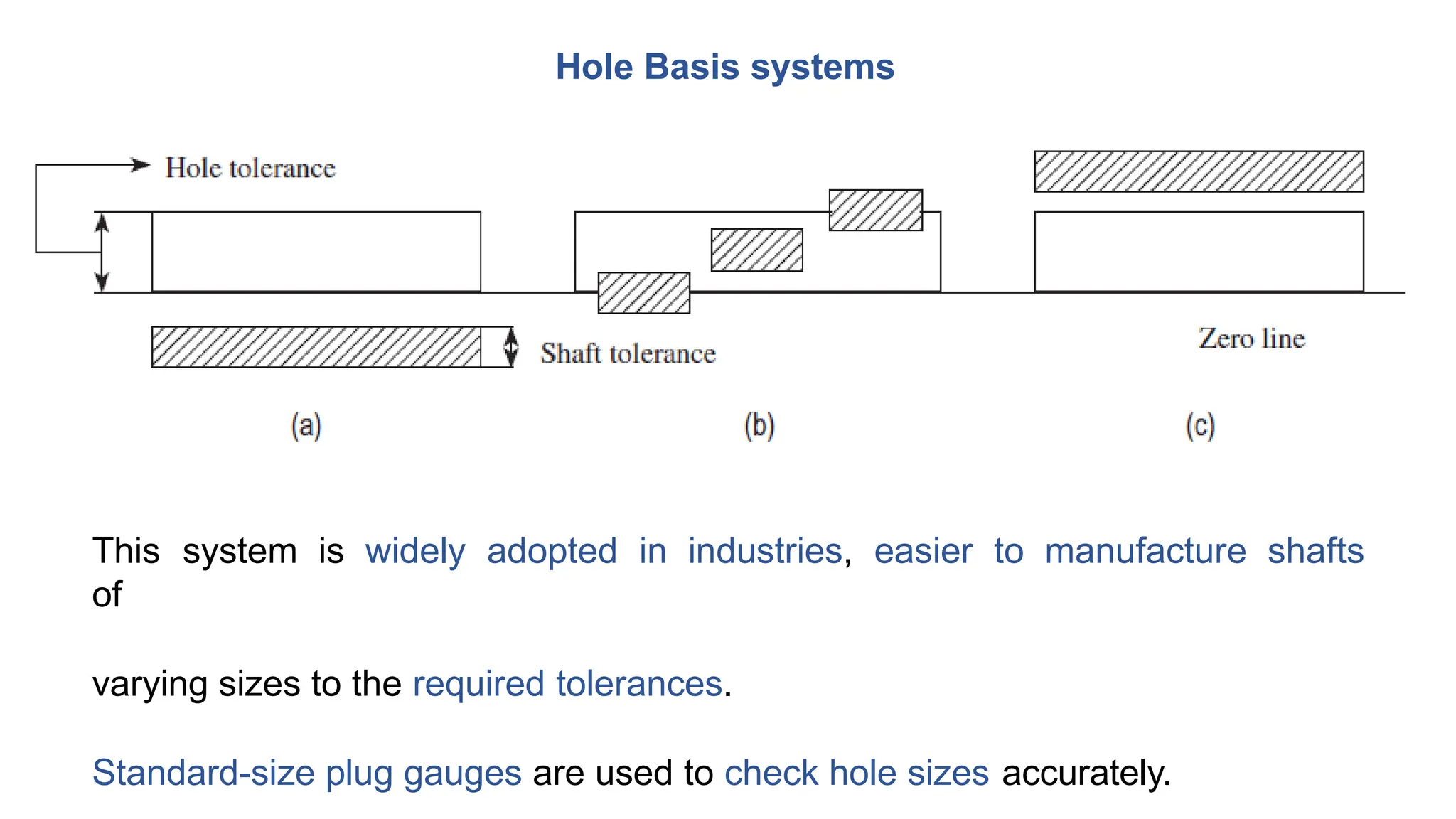

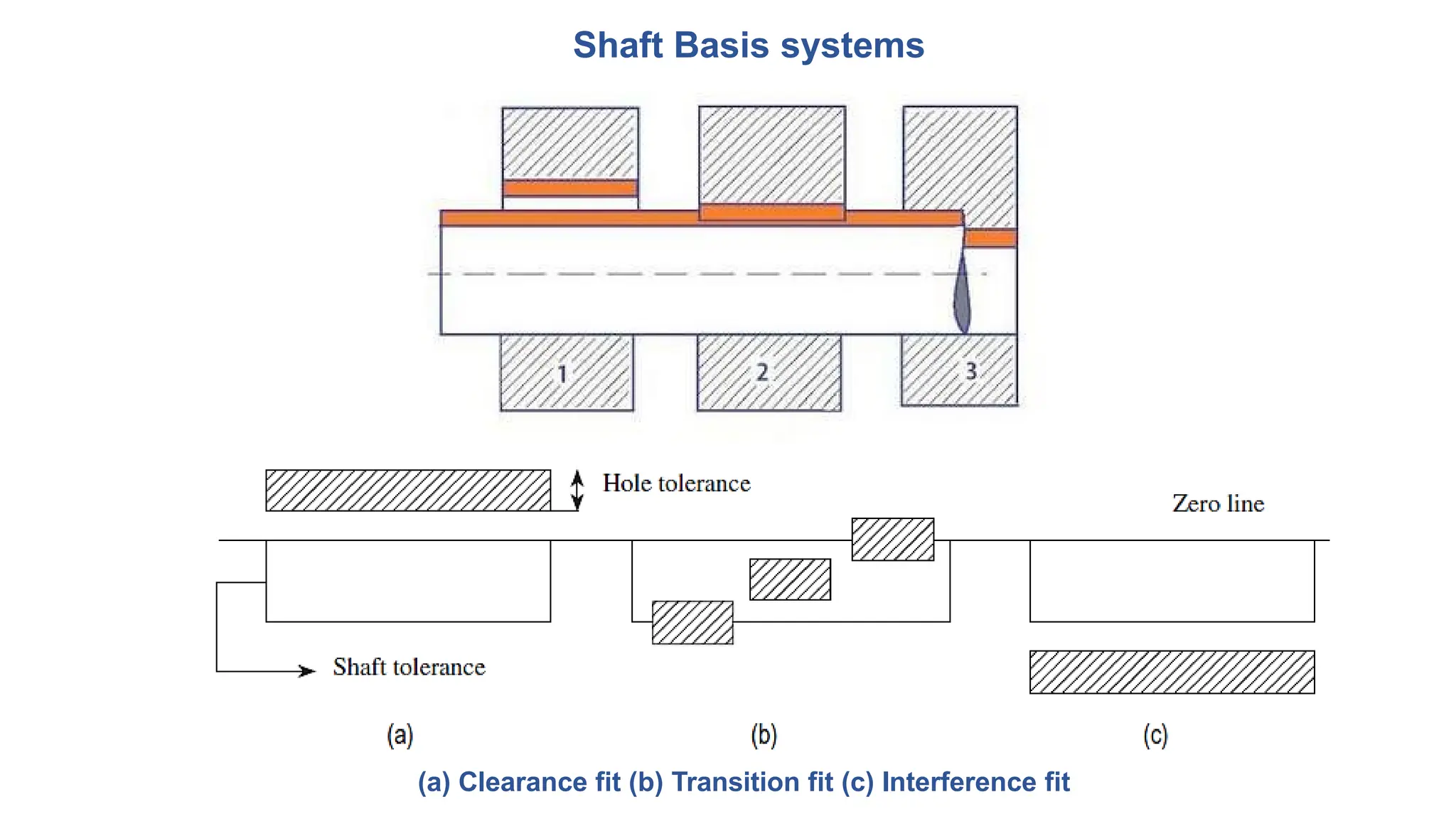

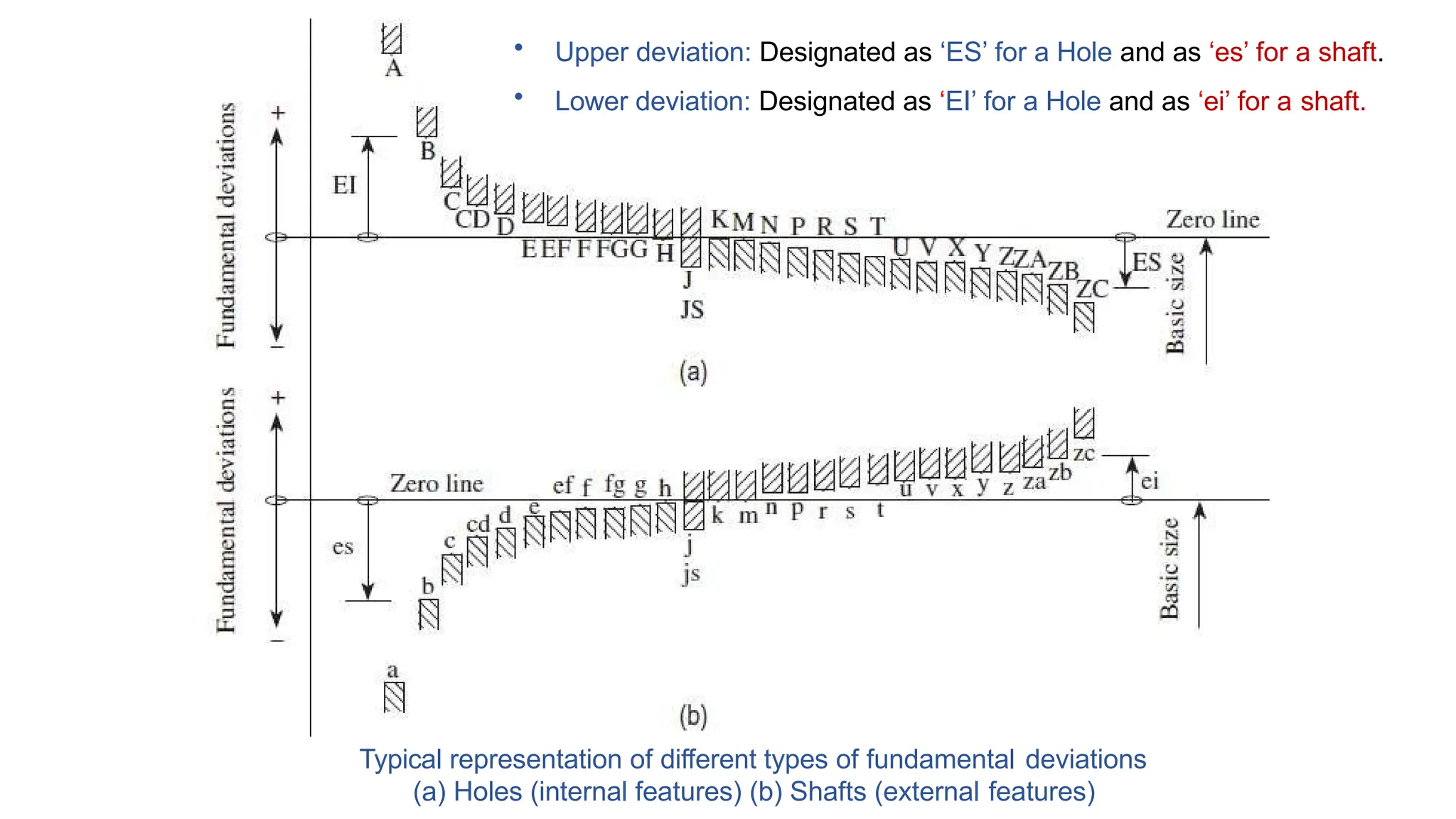

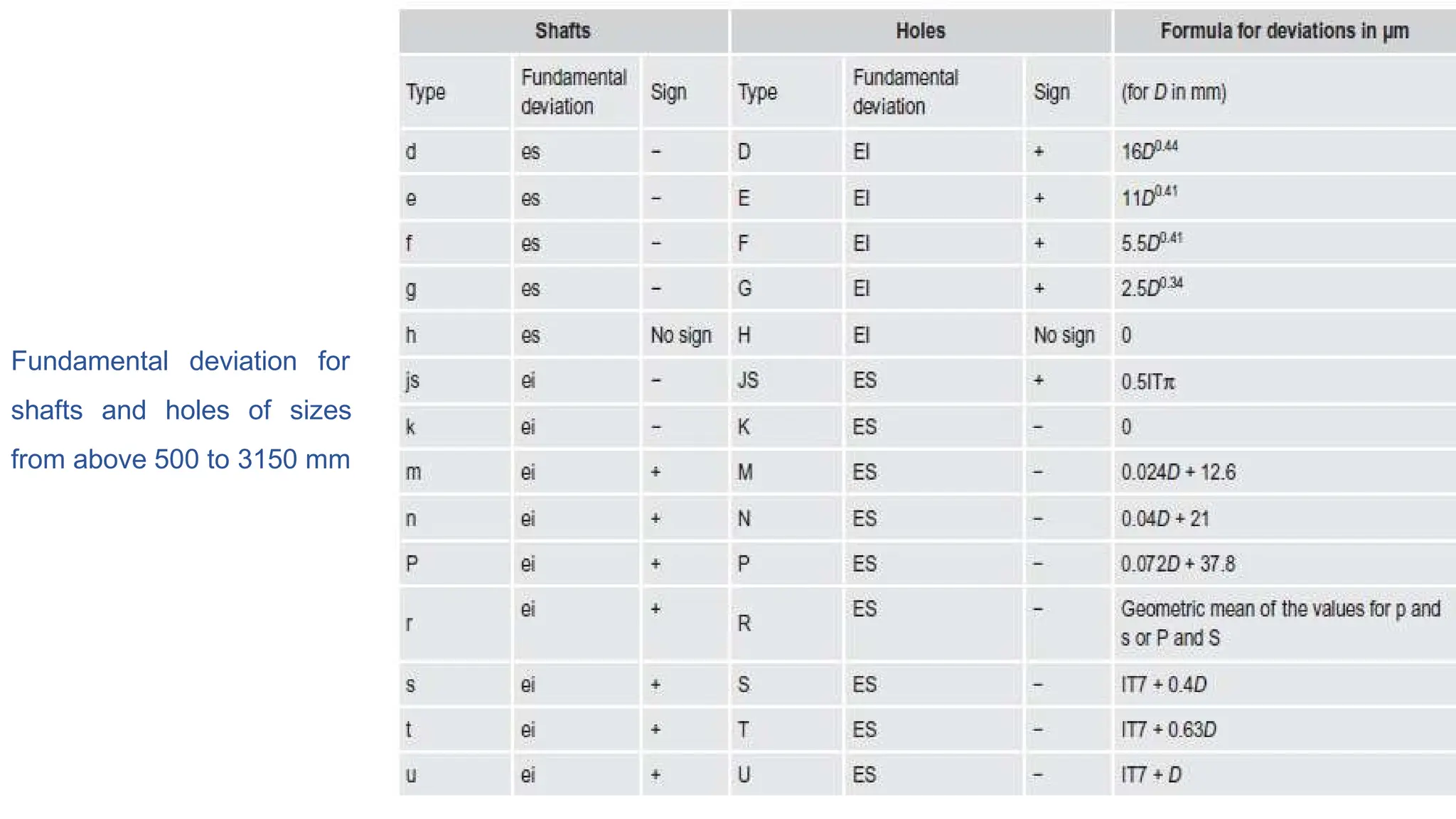

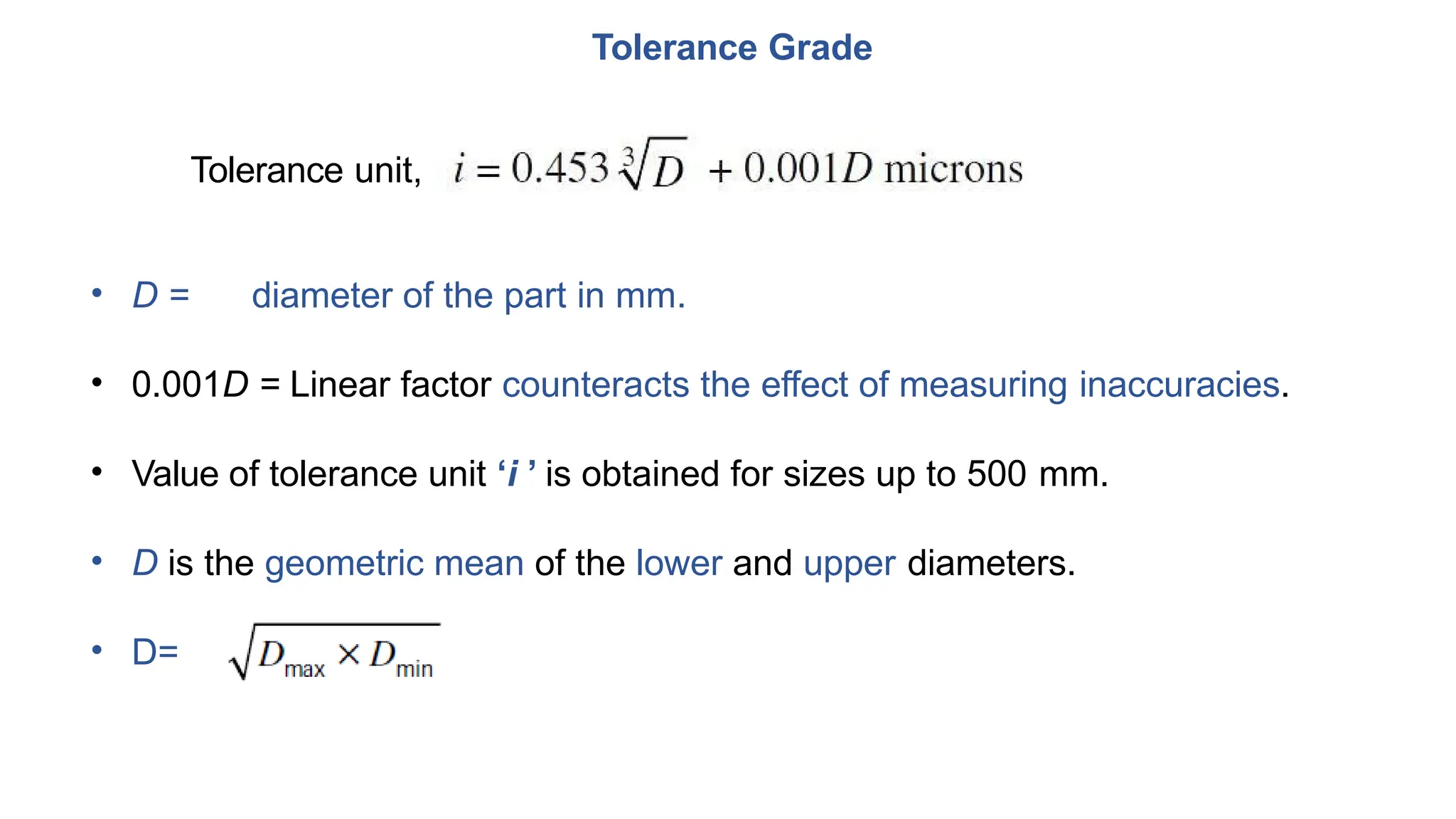

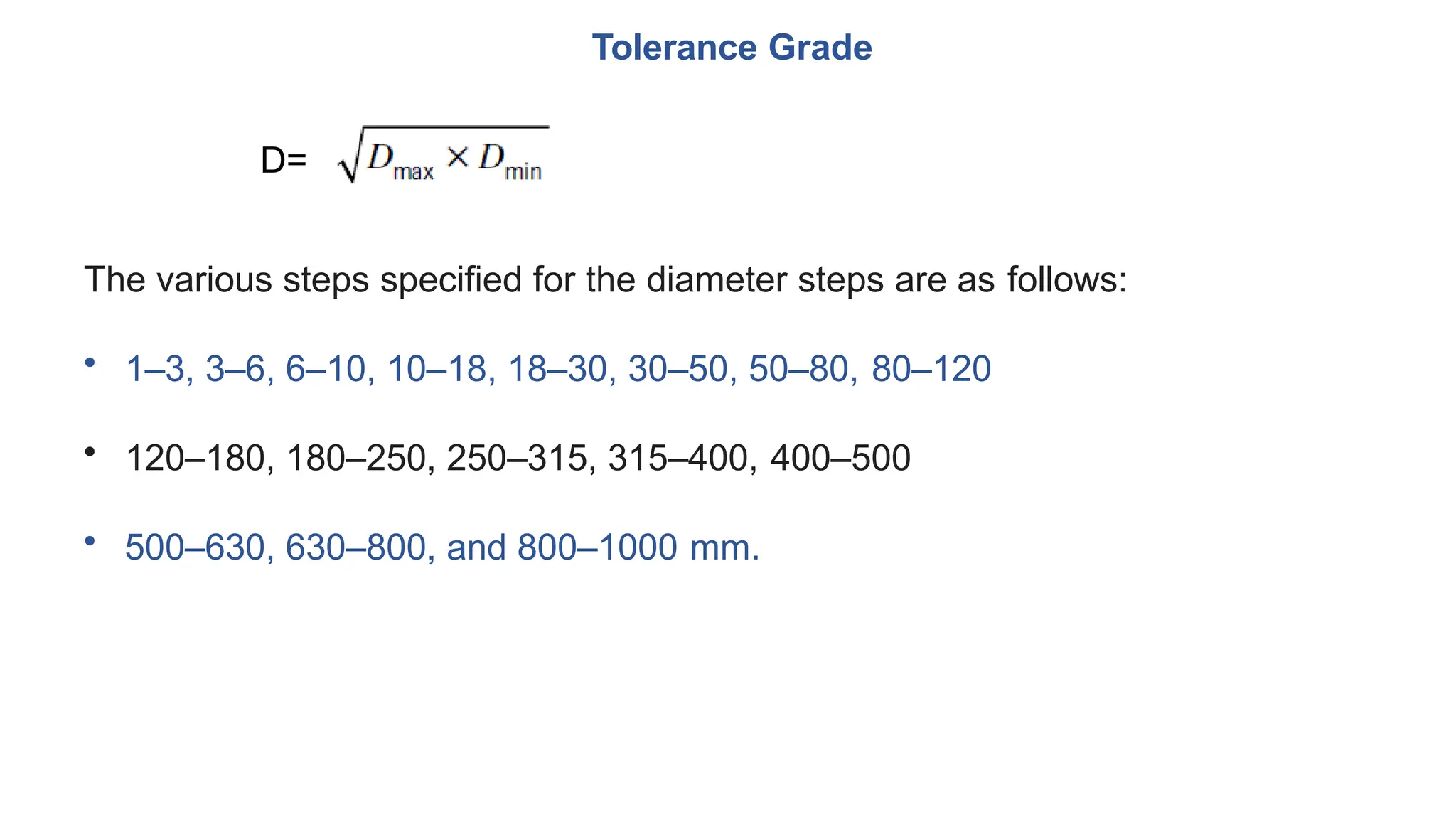

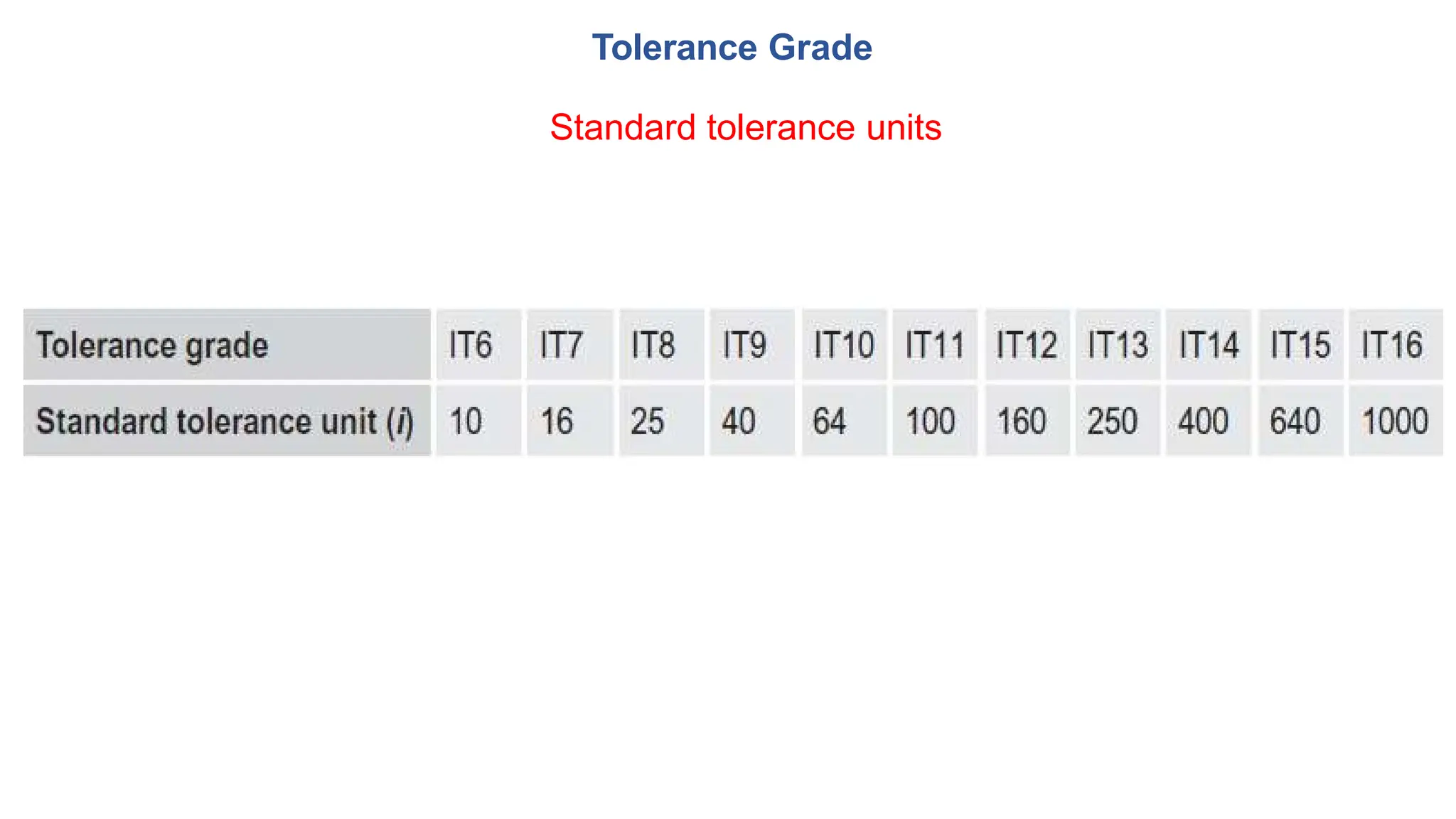

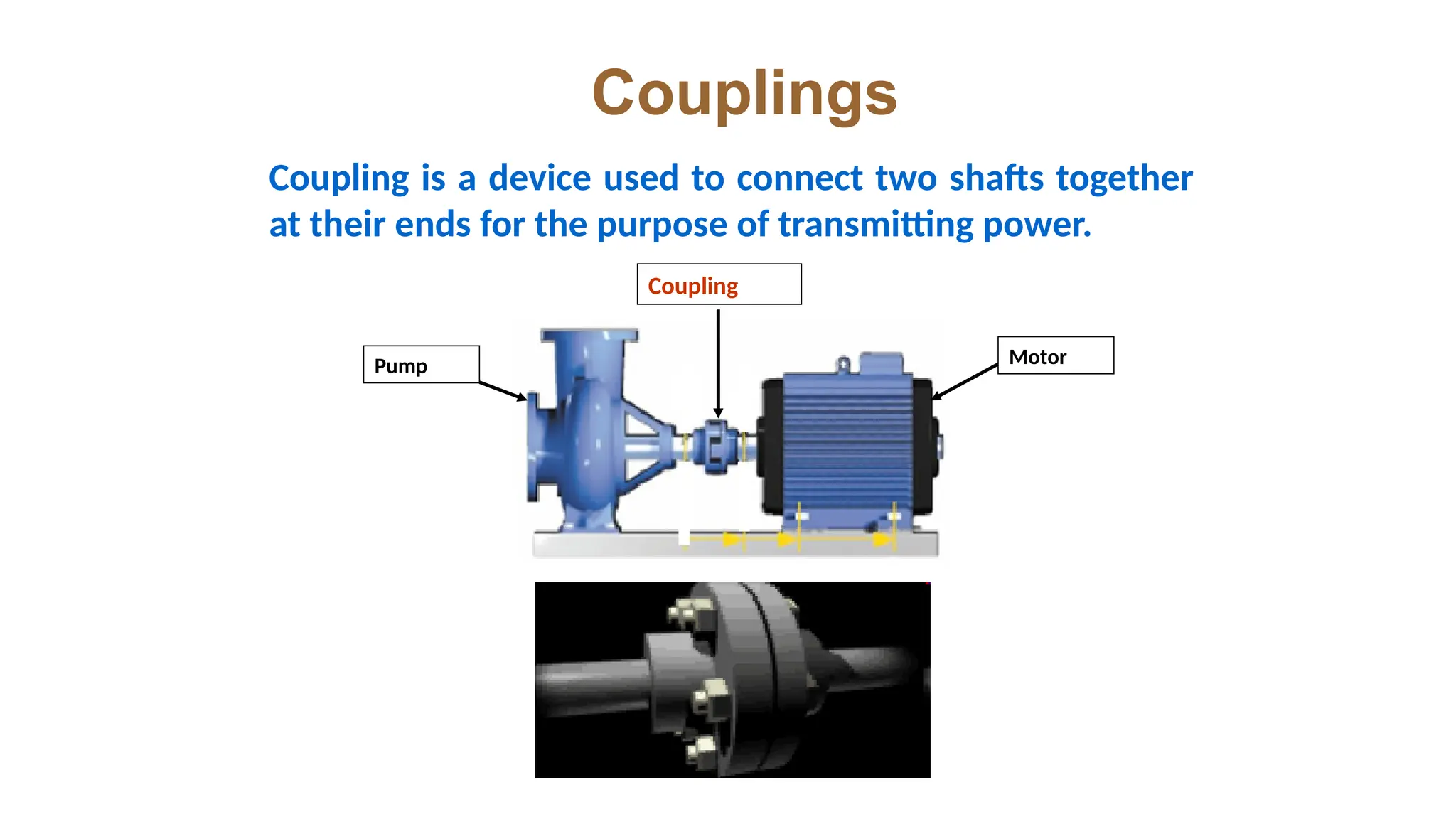

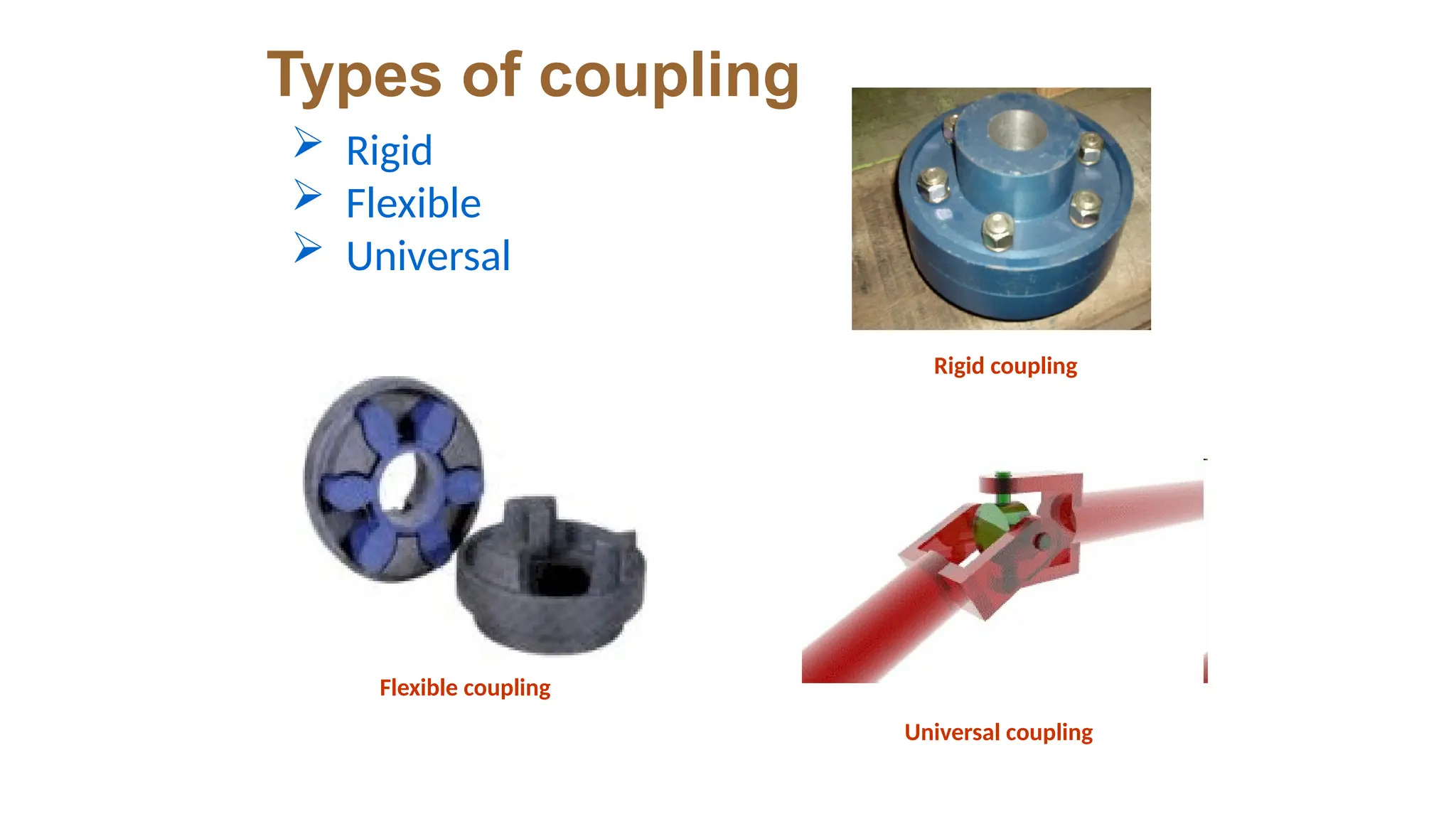

The document discusses the concepts of limits, fits, and tolerances in mechanical engineering, explaining the natural variations in manufacturing processes that necessitate tolerances for proper part functionality. It categorizes tolerances into unilateral, bilateral, compound, and geometric tolerances, along with different types of fits such as clearance, interference, and transition fits, essential for assembling parts accurately. Additionally, it covers the importance of understanding tolerance grades and the hole basis and shaft basis systems for achieving desired fits in mass production.