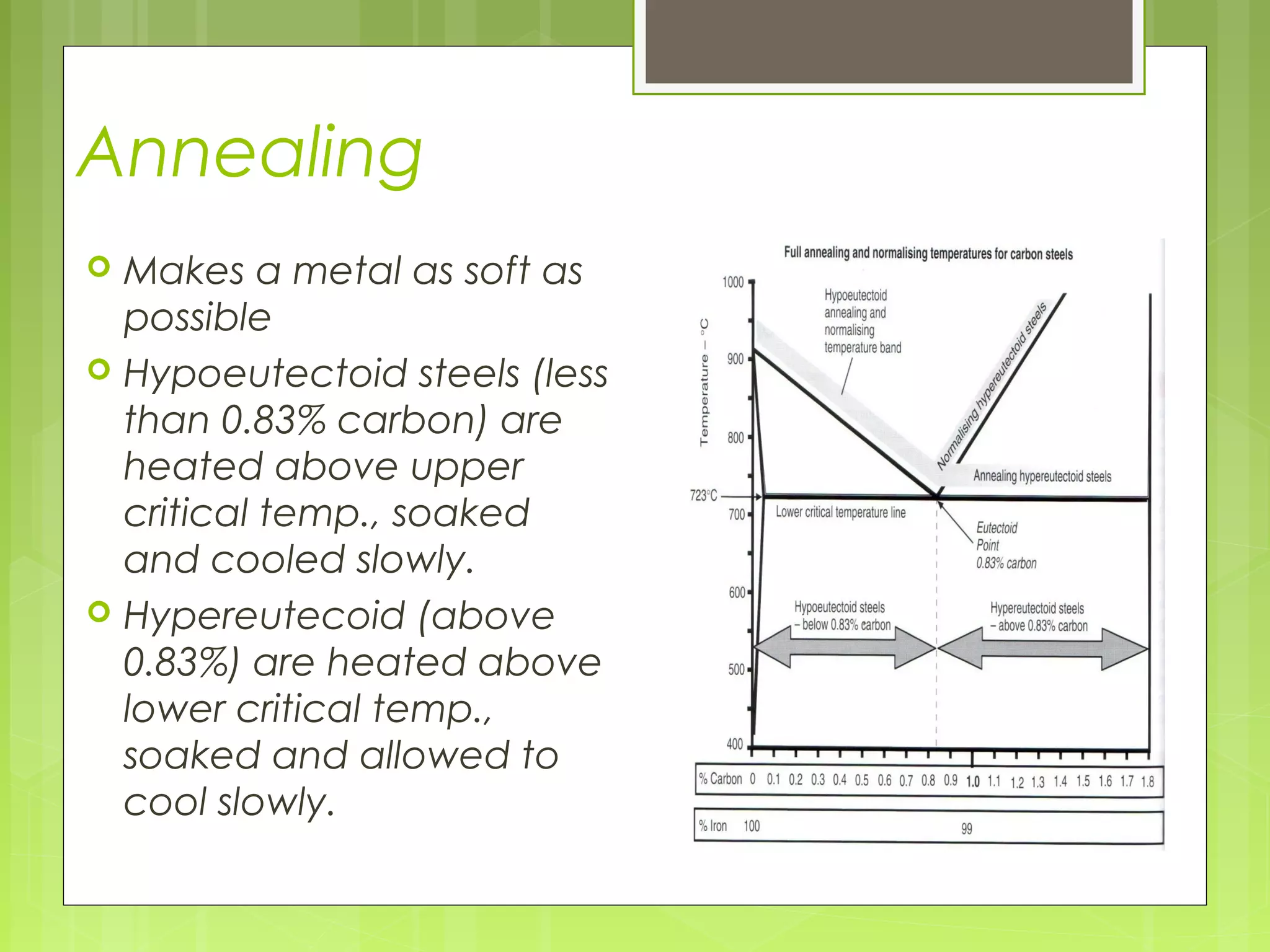

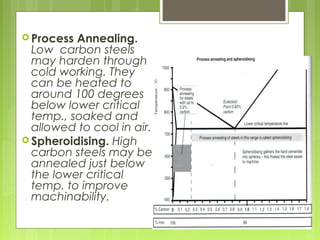

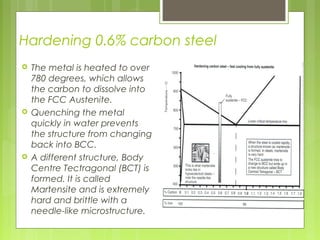

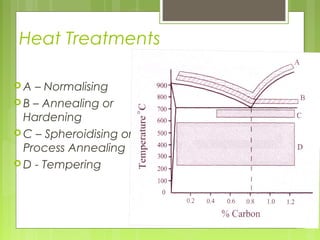

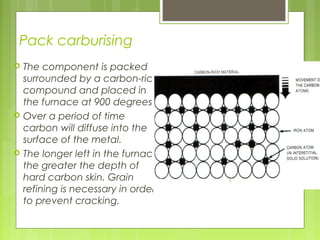

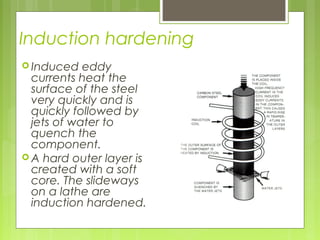

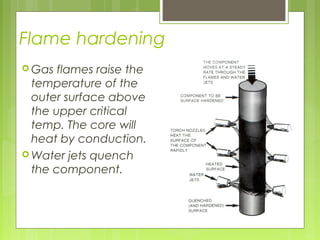

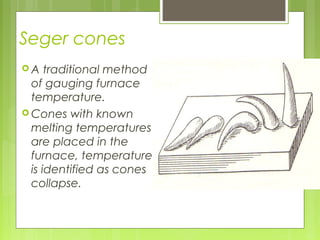

This document discusses various heat treatment processes for steels including annealing, normalizing, hardening, tempering, and case hardening. It explains that annealing involves heating metals above or below critical temperatures and slowly cooling to make the metal soft. Hardening involves heating steel above its critical temperature then quenching in water to form martensite and make the metal very hard. Tempering is used after hardening to reduce brittleness by reheating to 220-300 degrees C. Case hardening, such as carburizing or nitriding, adds carbon or nitrogen to the surface layer to harden low-carbon steels. Methods of measuring temperature in furnaces like pyrometers and Seger cones are also summarized