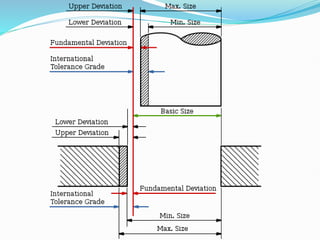

- Limits, tolerances, and fits refer to permissible variations in part dimensions to enable interchangeability.

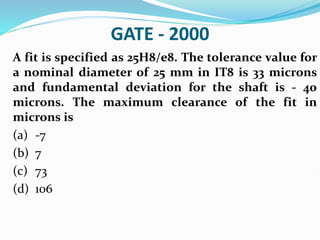

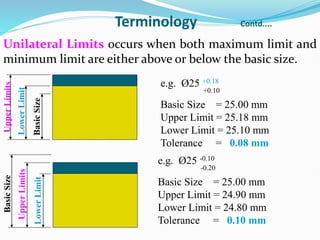

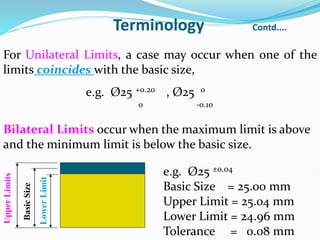

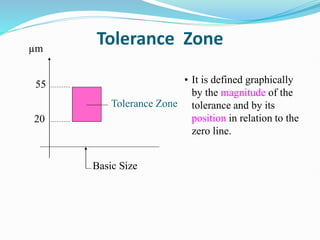

- A tolerance is the acceptable range between an upper and lower limit. It allows for manufacturing variability.

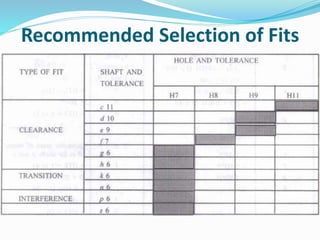

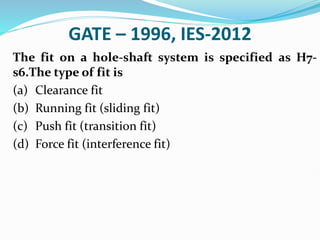

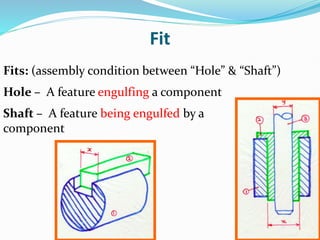

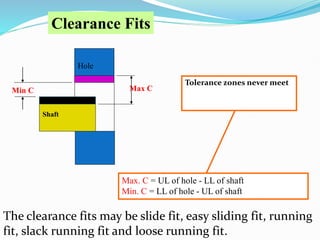

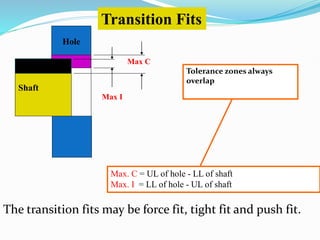

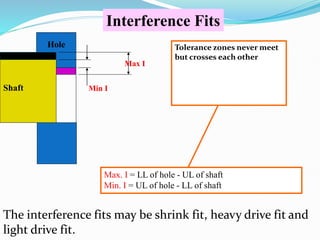

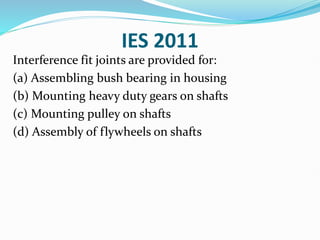

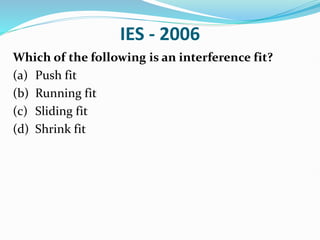

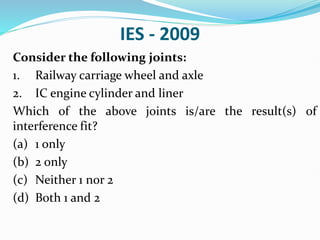

- Fits include clearance, transition, and interference fits depending on whether tolerance zones overlap or not.

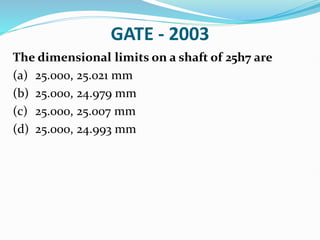

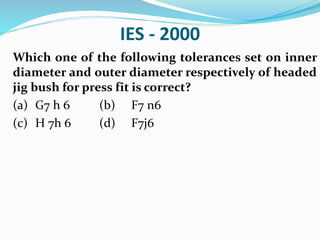

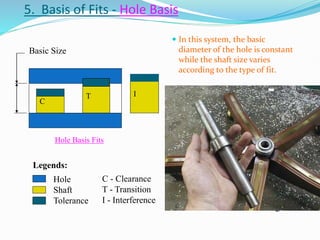

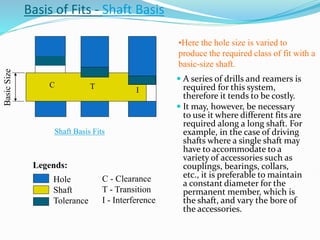

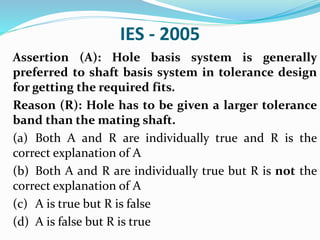

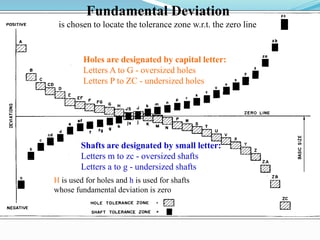

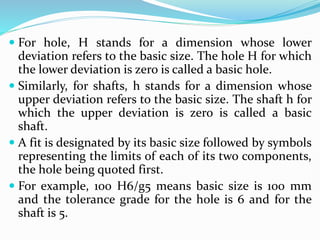

- Hole and shaft basis refer to specifying tolerances relative to the hole or shaft dimension as a reference.

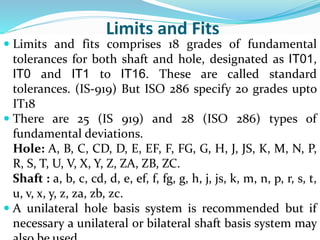

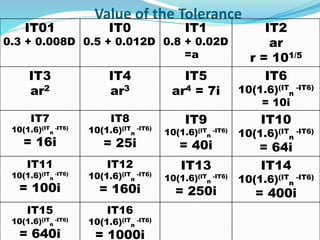

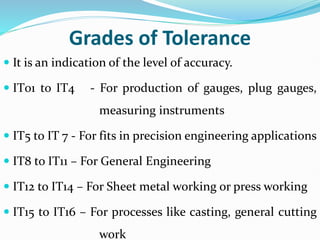

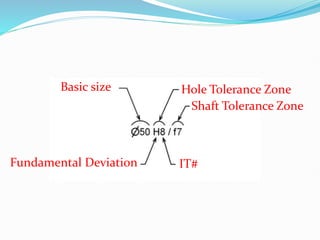

- Standard tolerances grades like IT01 to IT16 indicate the accuracy level needed for the application.

![Tolerance Designation (ISO)

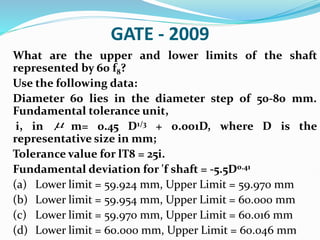

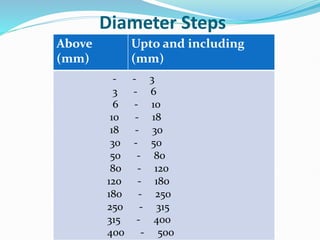

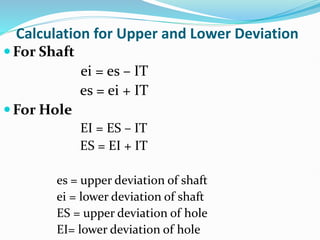

Tolerance on a shaft or a hole can also be calculated by

using the formulas provided by ISO.

i

K

T

where,

T is the tolerance (in µm)

D

D

i 001

.

0

45

.

0 3

(unit tolerance, in µm)

2

1D

D

D (D1 and D2 are the nominal sizes marking

the beginning and the end of a range of

sizes, in mm)

6

6

.

1

10 IT

ITn

K

[For IT6 to IT16]](https://image.slidesharecdn.com/ch-24limittolerancefits-240121161422-fbdcbee9/85/Ch-24-Limit-Tolerance-Fits-pptx-32-320.jpg)

![IES-2006 Conventional

Find the limit sizes, tolerances and allowances for a

100 mm diameter shaft and hole pair designated by

F8h10. Also specify the type of fit that the above pair

belongs to.

Given: 100 mm diameter lies in the diameter step

range of 80-120 mm. The fundamental deviation for

shaft designation ‘f’ is -5.5 D0.41

The values of standard tolerances for grades of IT 8

and IT 10 are 25i and 64i respectively.

Also, indicate the limits and tolerance on a diagram.

[15-Marks]](https://image.slidesharecdn.com/ch-24limittolerancefits-240121161422-fbdcbee9/85/Ch-24-Limit-Tolerance-Fits-pptx-41-320.jpg)