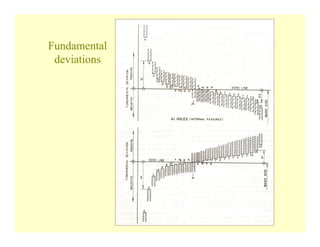

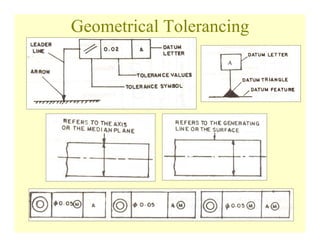

The document discusses tolerance analysis and various causes of workpiece variation including machine inaccuracies, tool wear, material variations, and human error. It defines key tolerance terms like nominal size, basic size, allowance, and tolerance. Diagrams are shown to illustrate basic size deviations and tolerances. Methods for expressing tolerances include tolerance grades, fundamental deviations, and fits for holes. Geometric tolerancing symbols are also explained. The problems of tolerance stacking and controlling product limits during processing are covered. Optimizing the sequence of operations can help maintain tolerances without tightening tolerances unnecessarily.