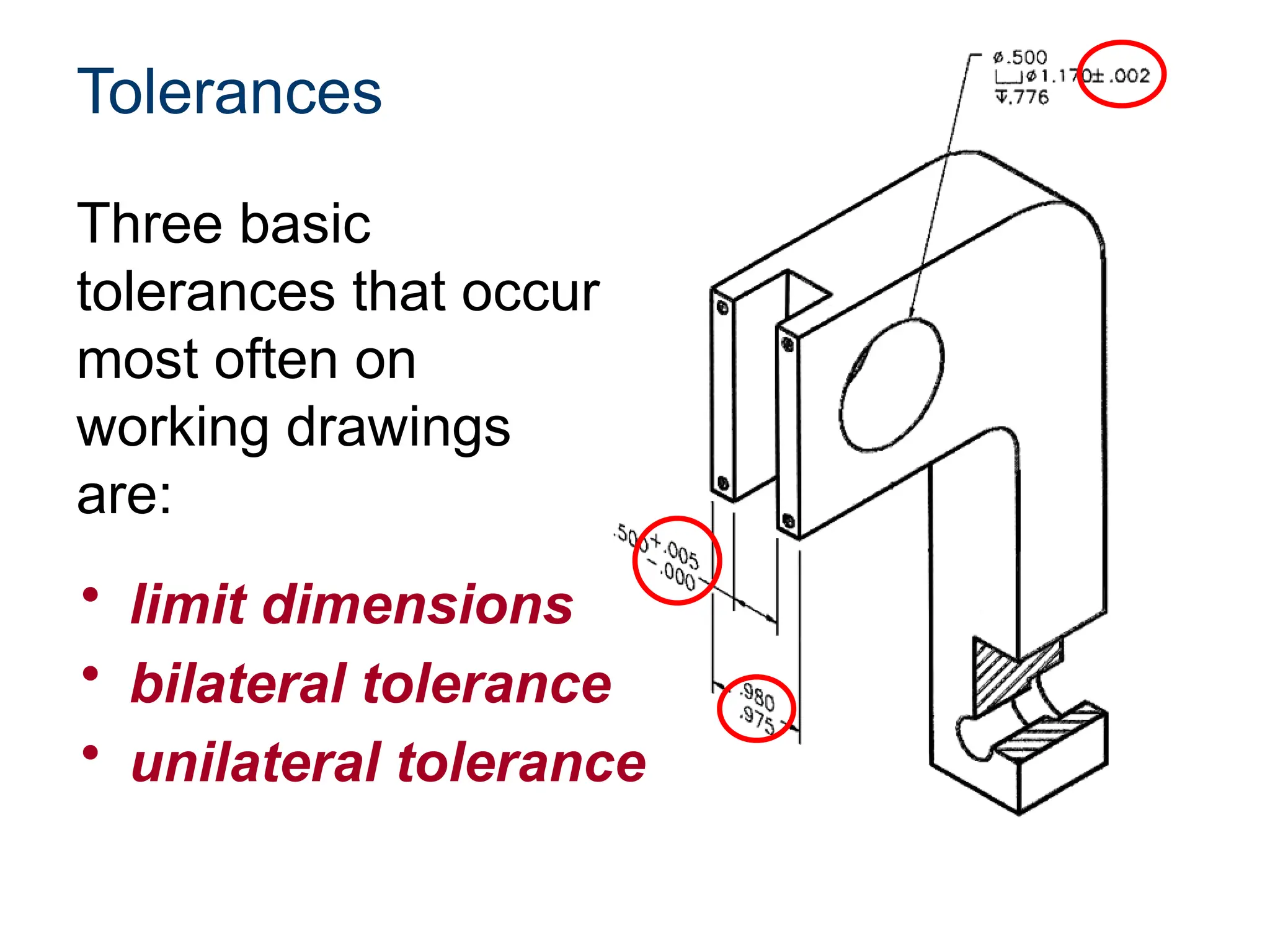

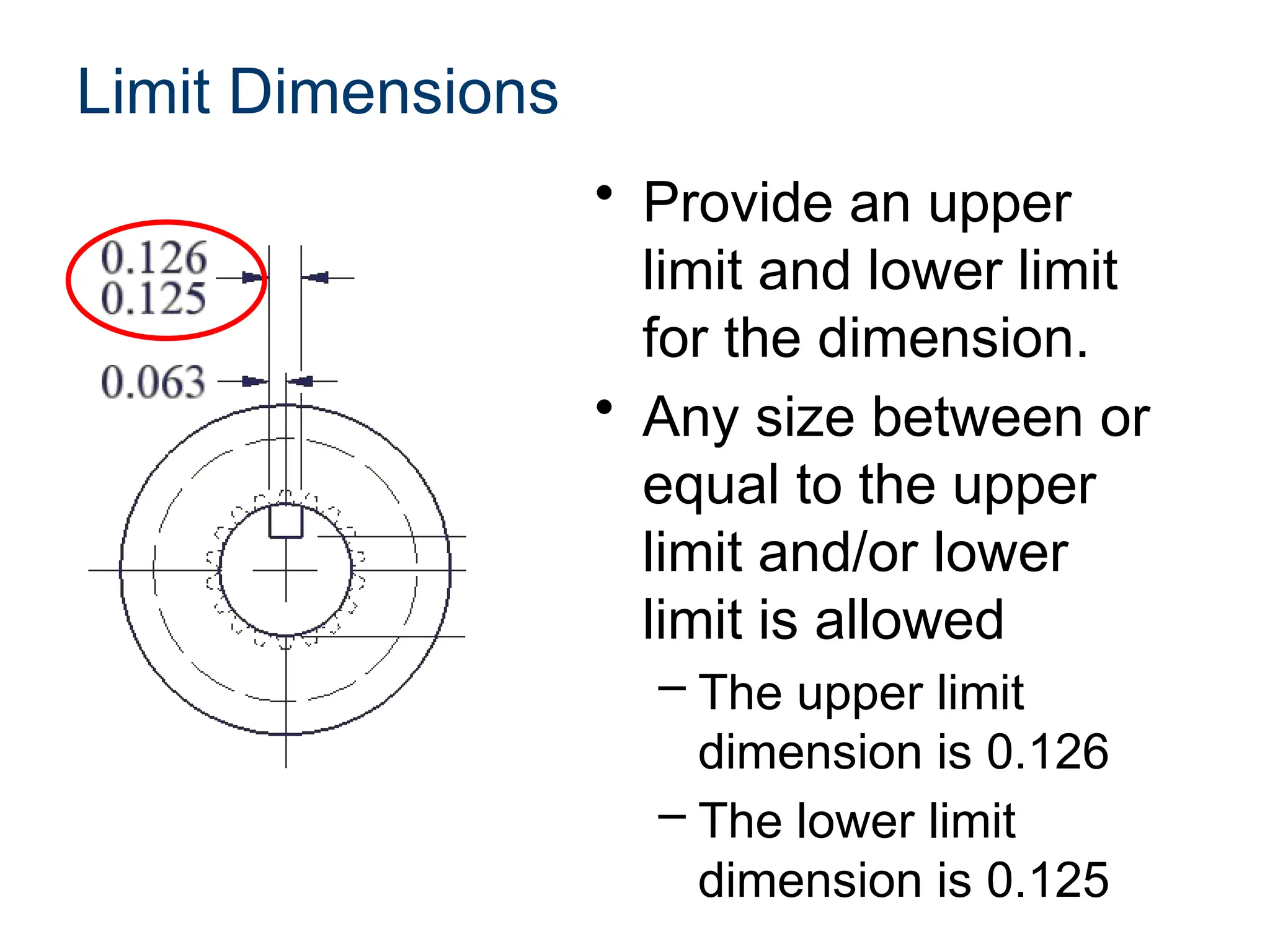

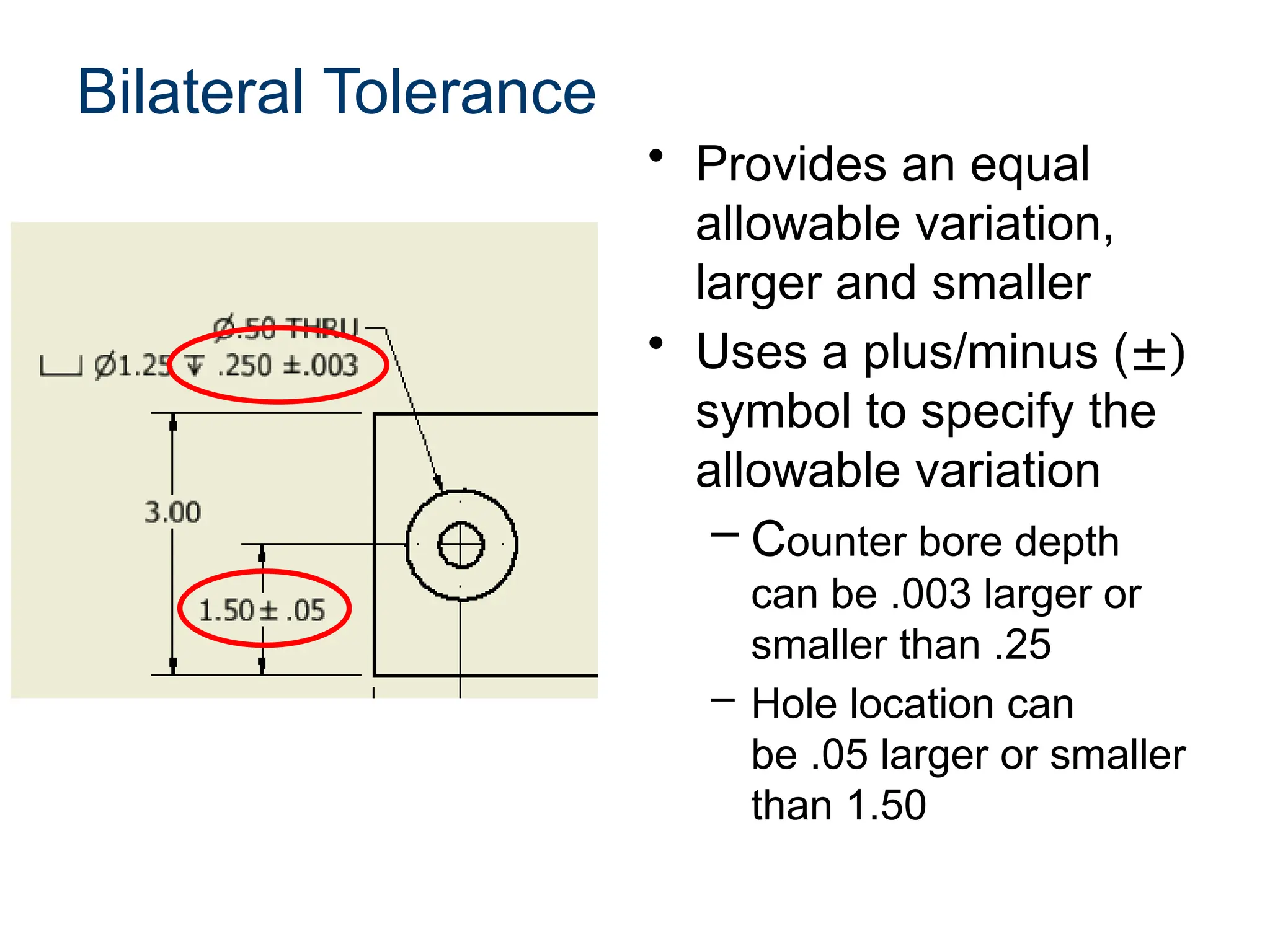

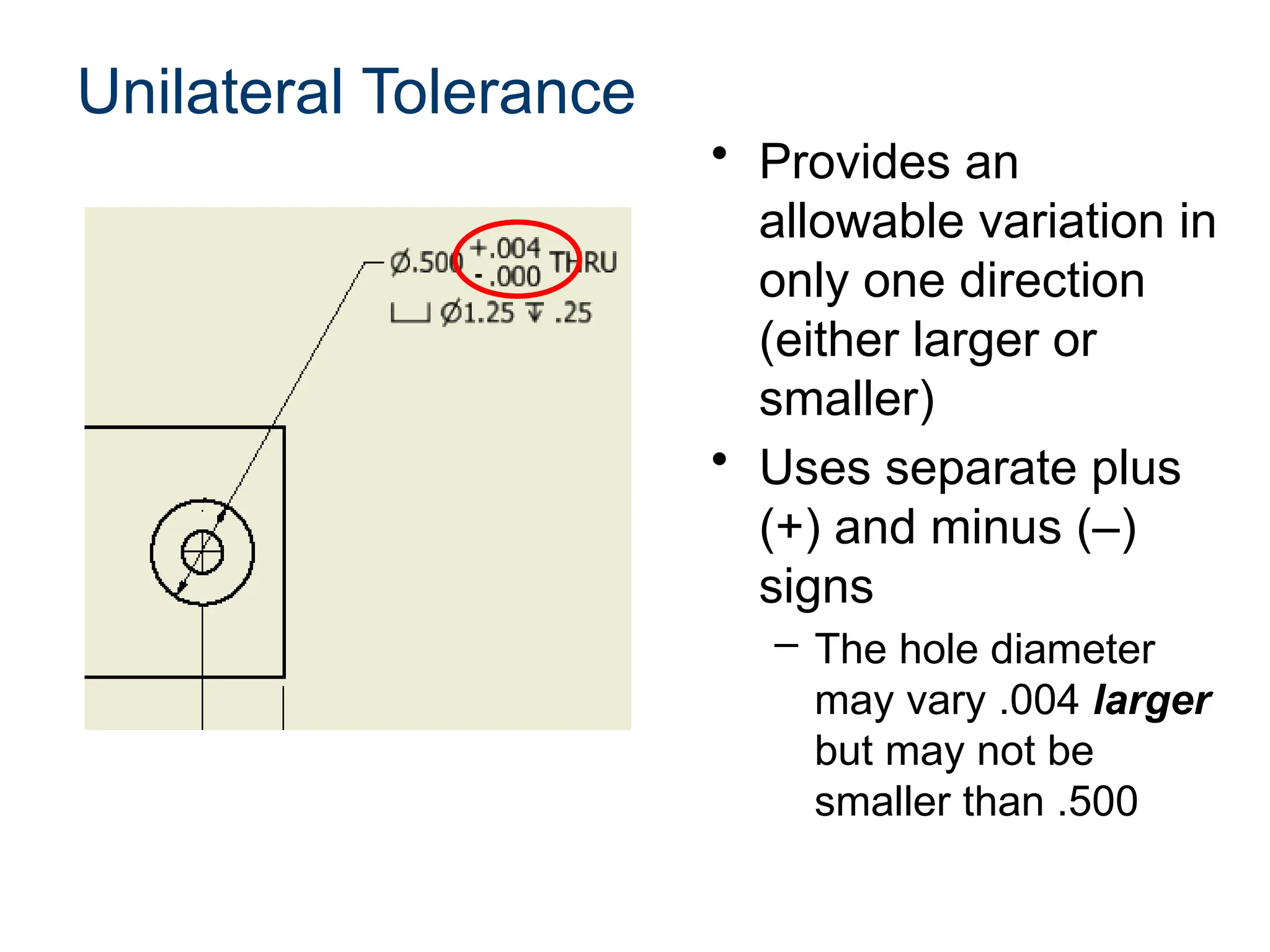

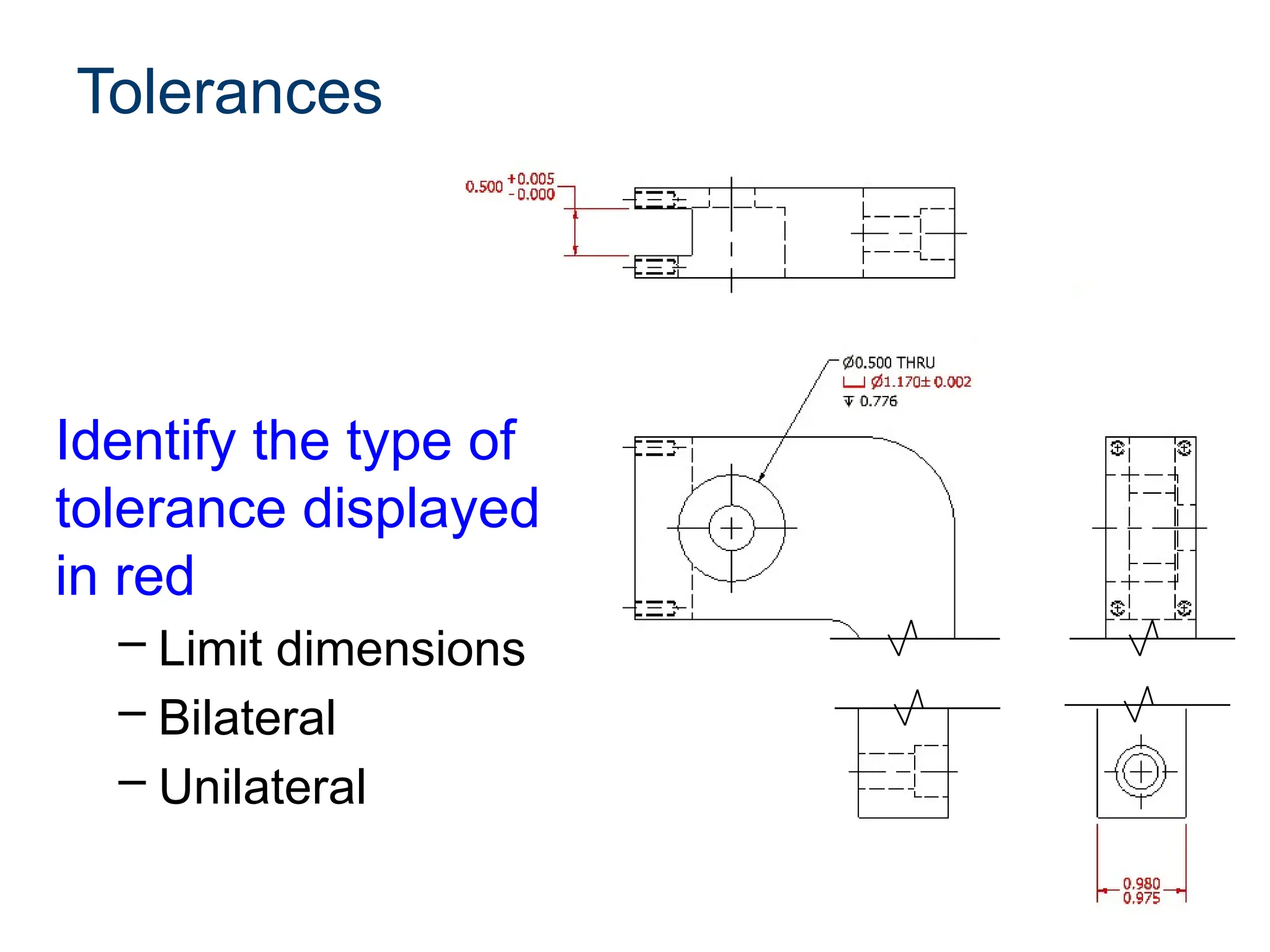

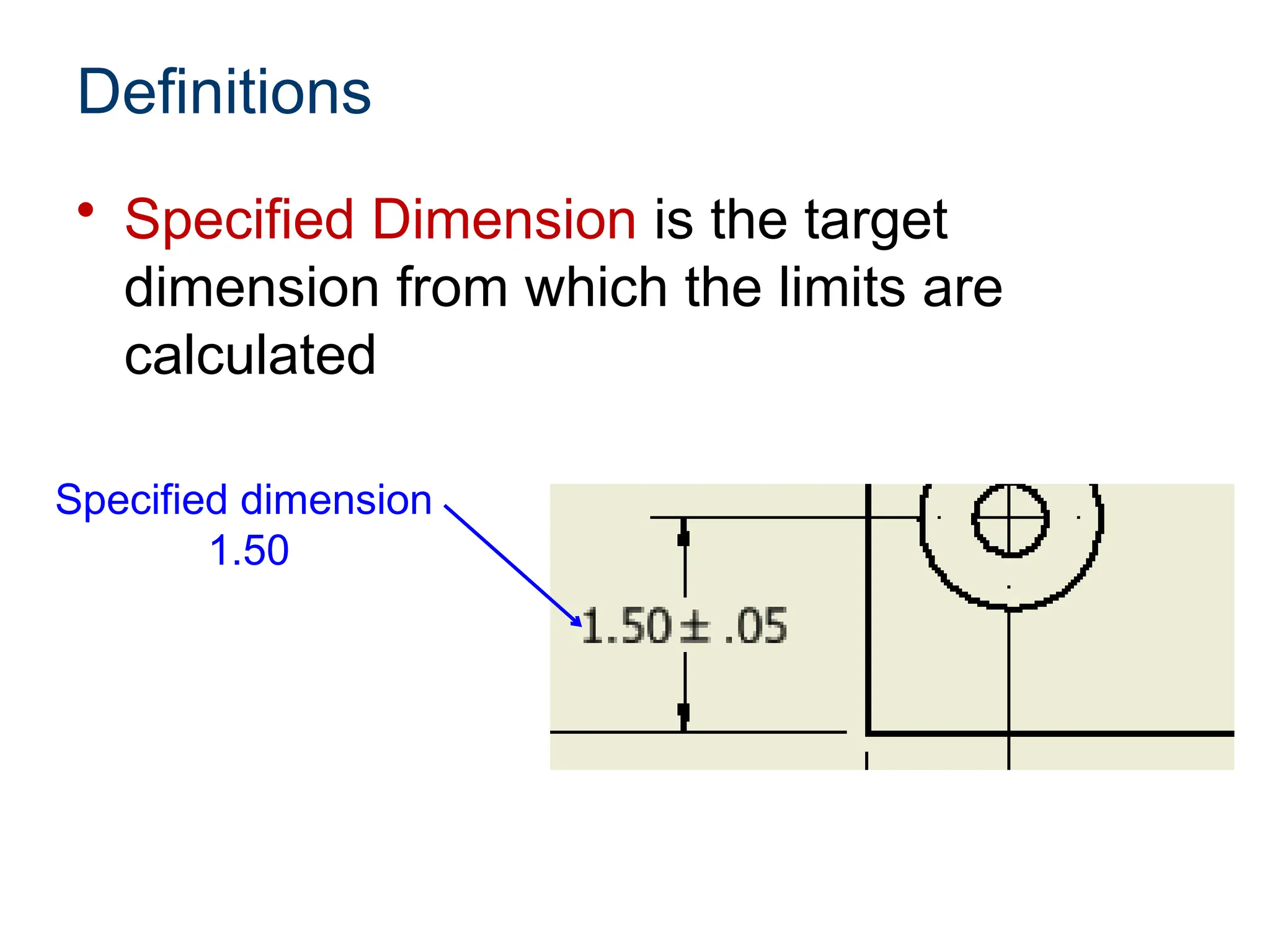

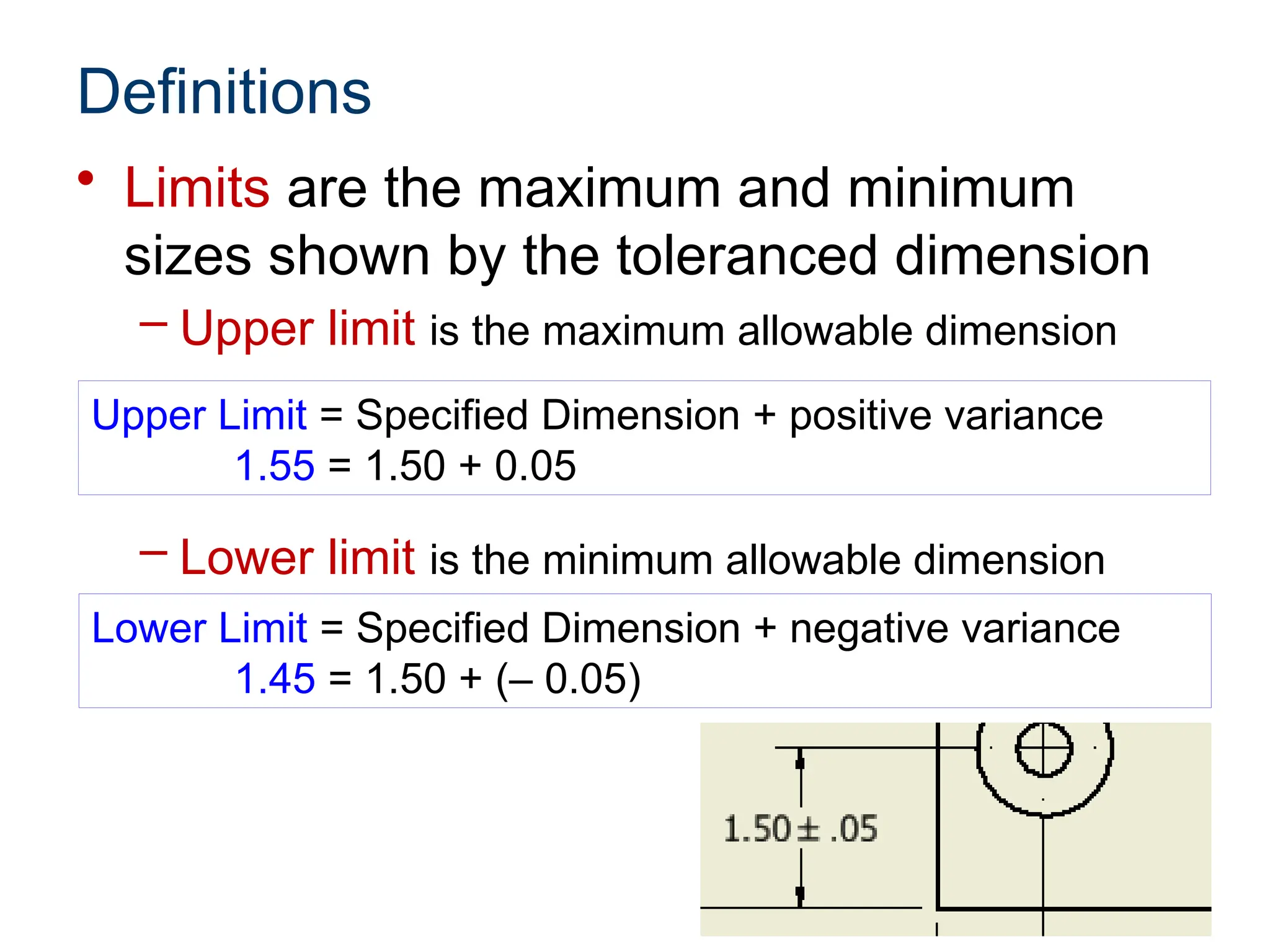

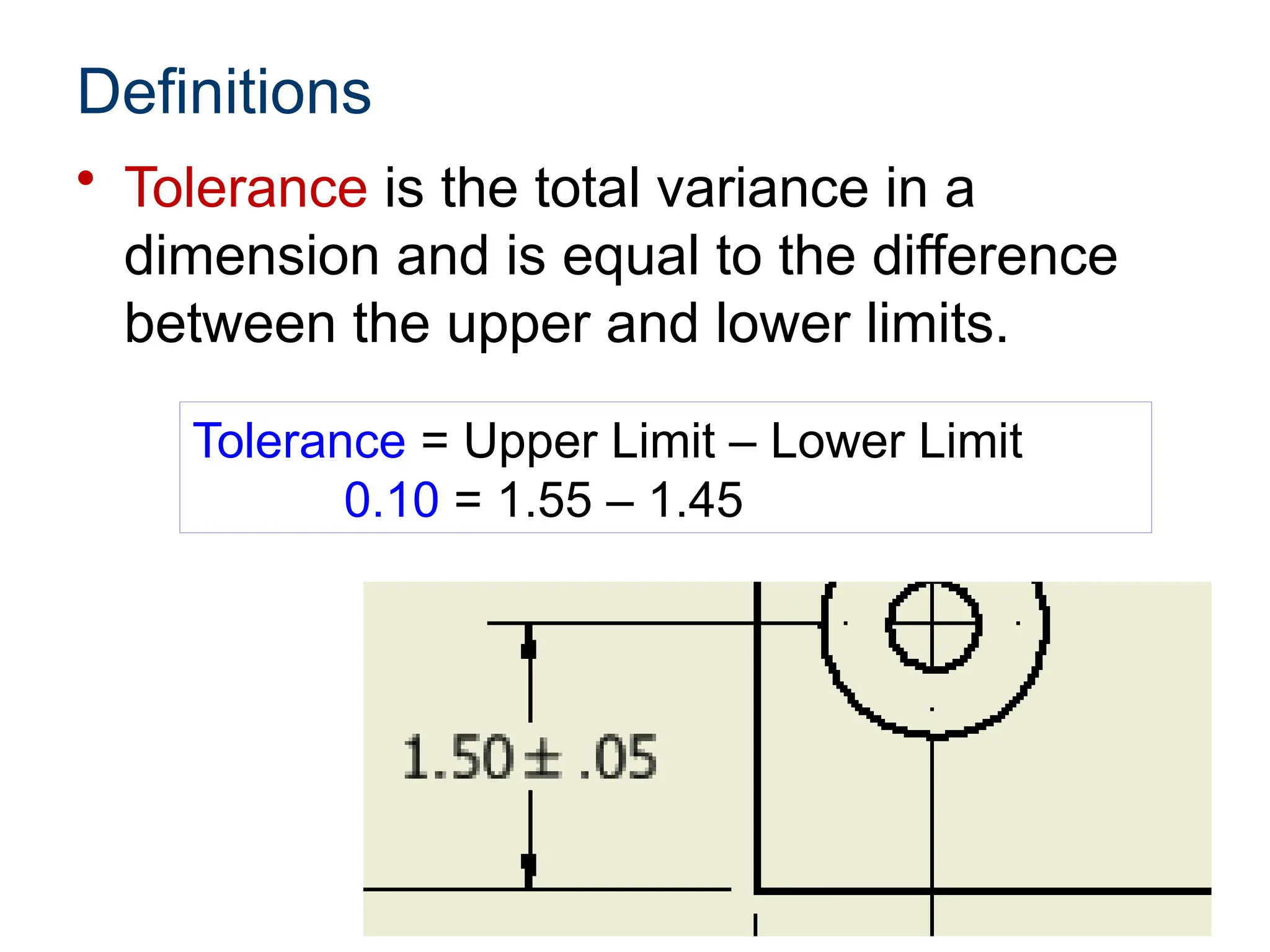

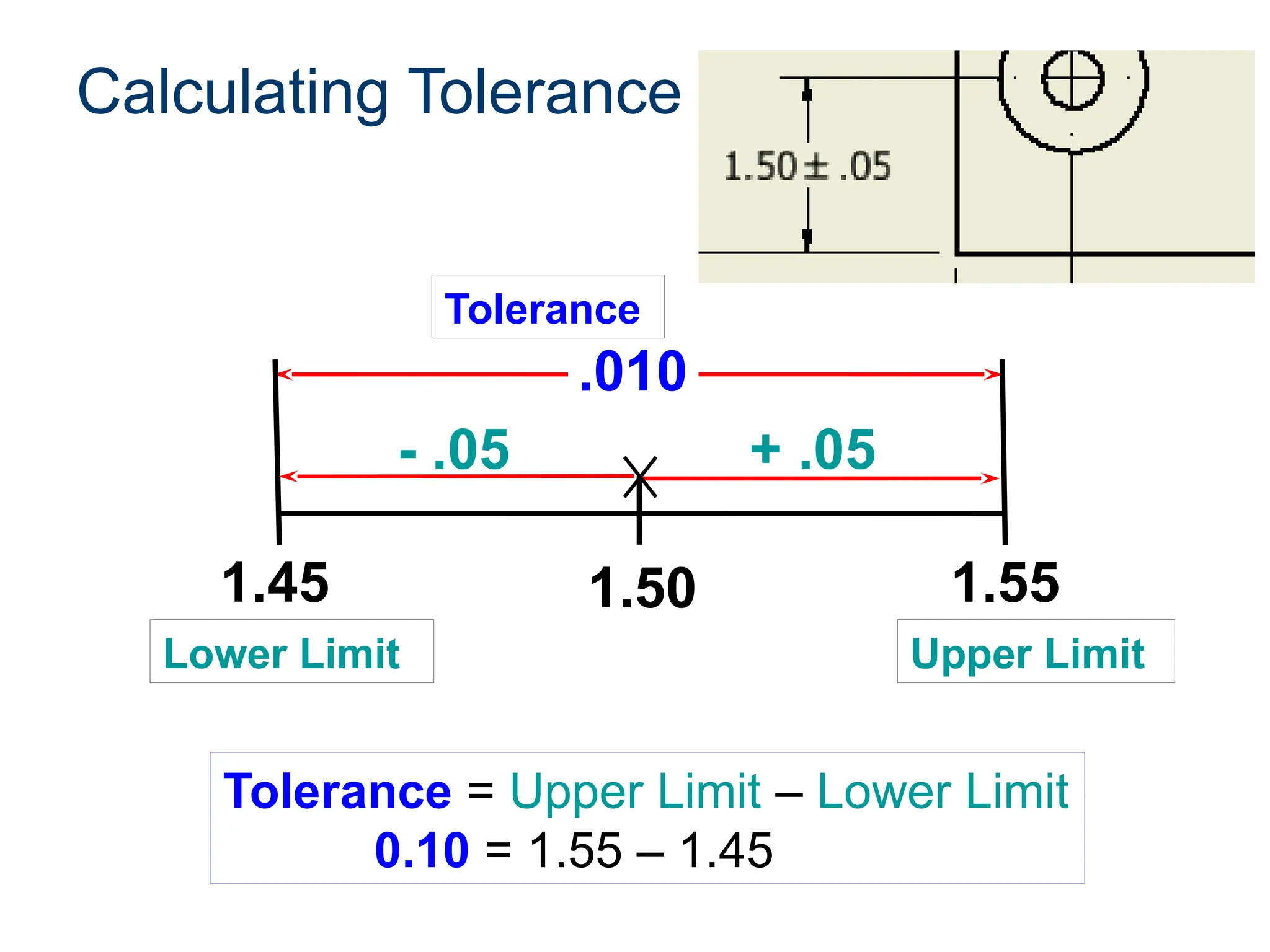

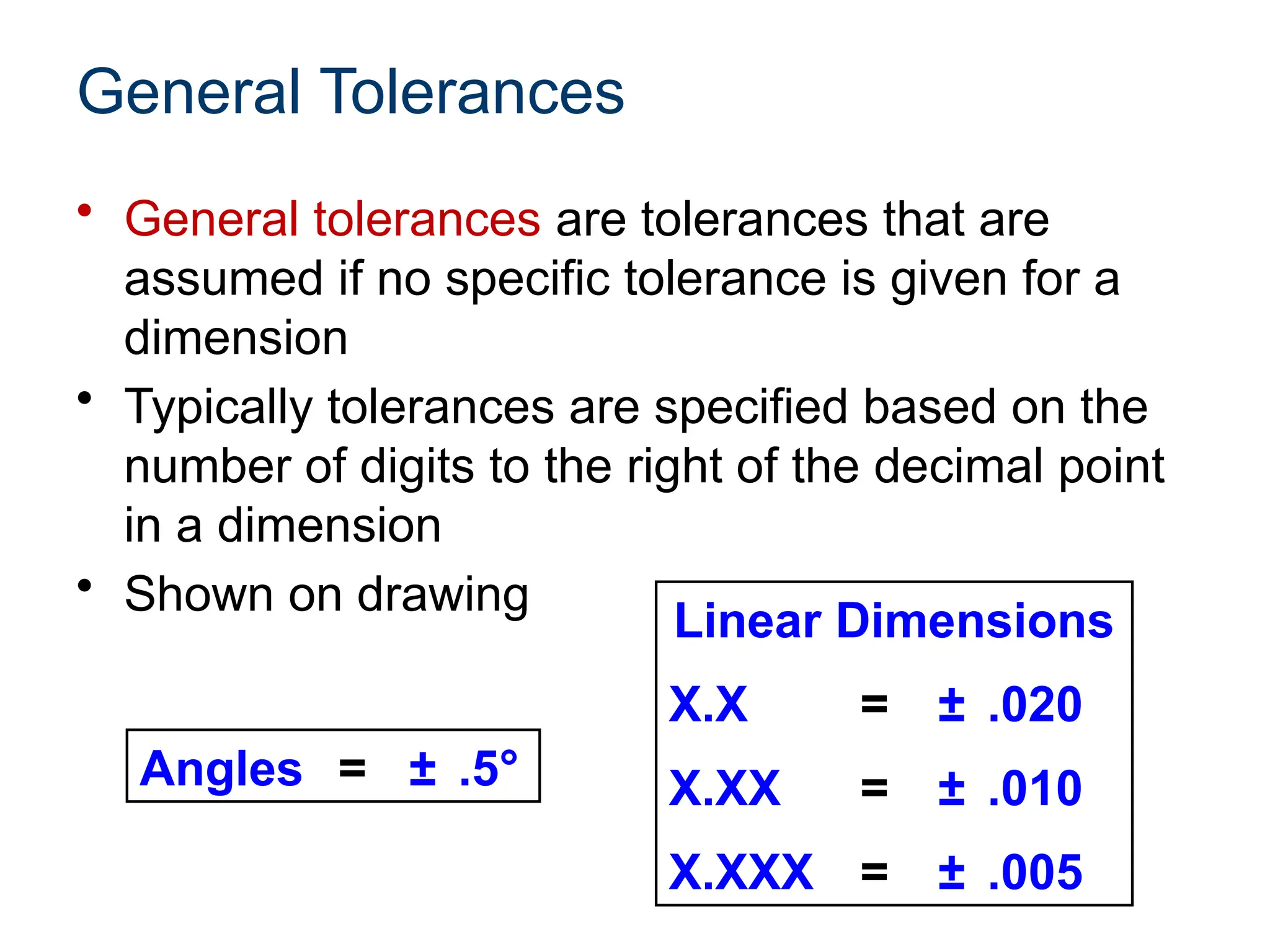

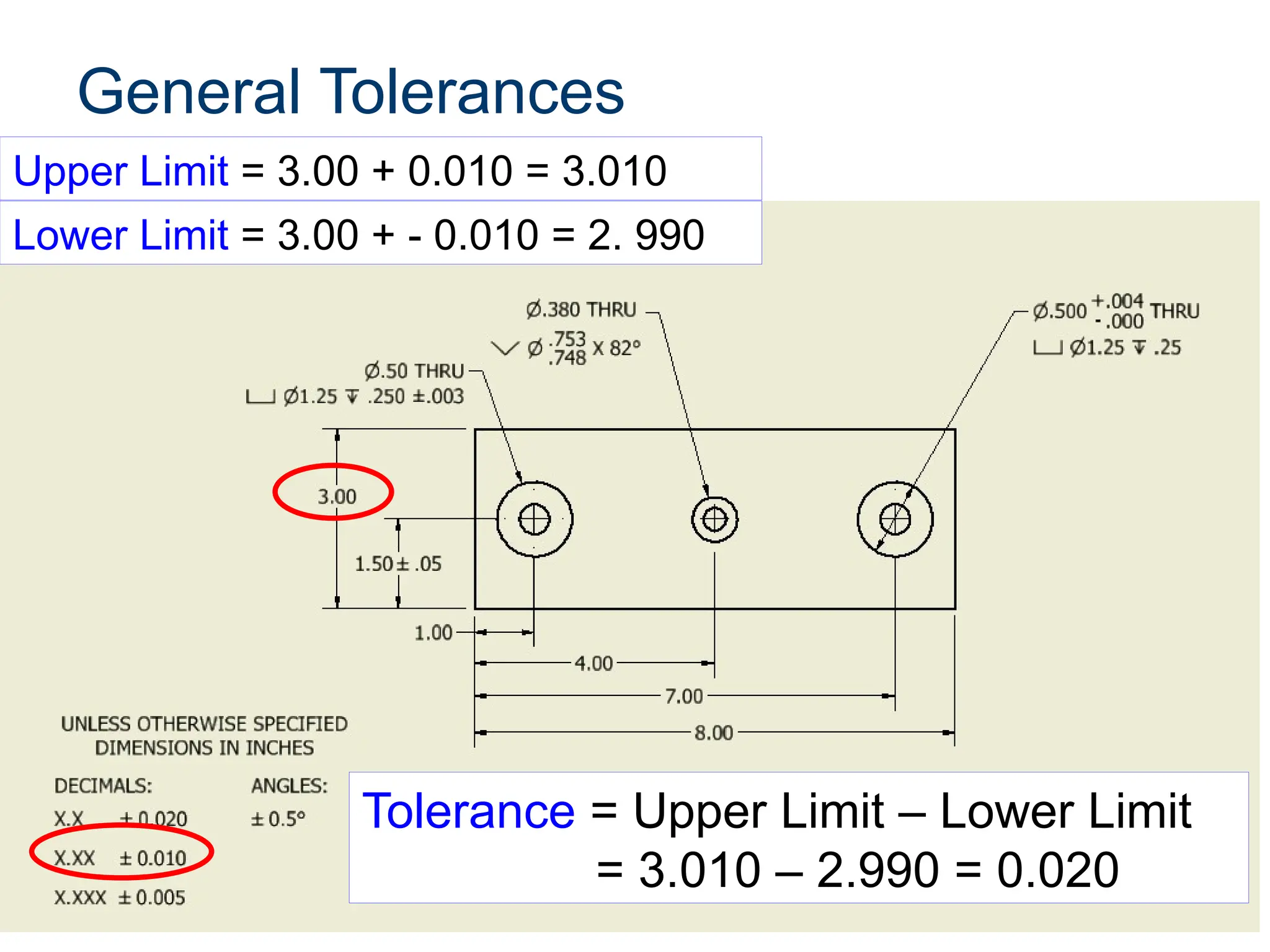

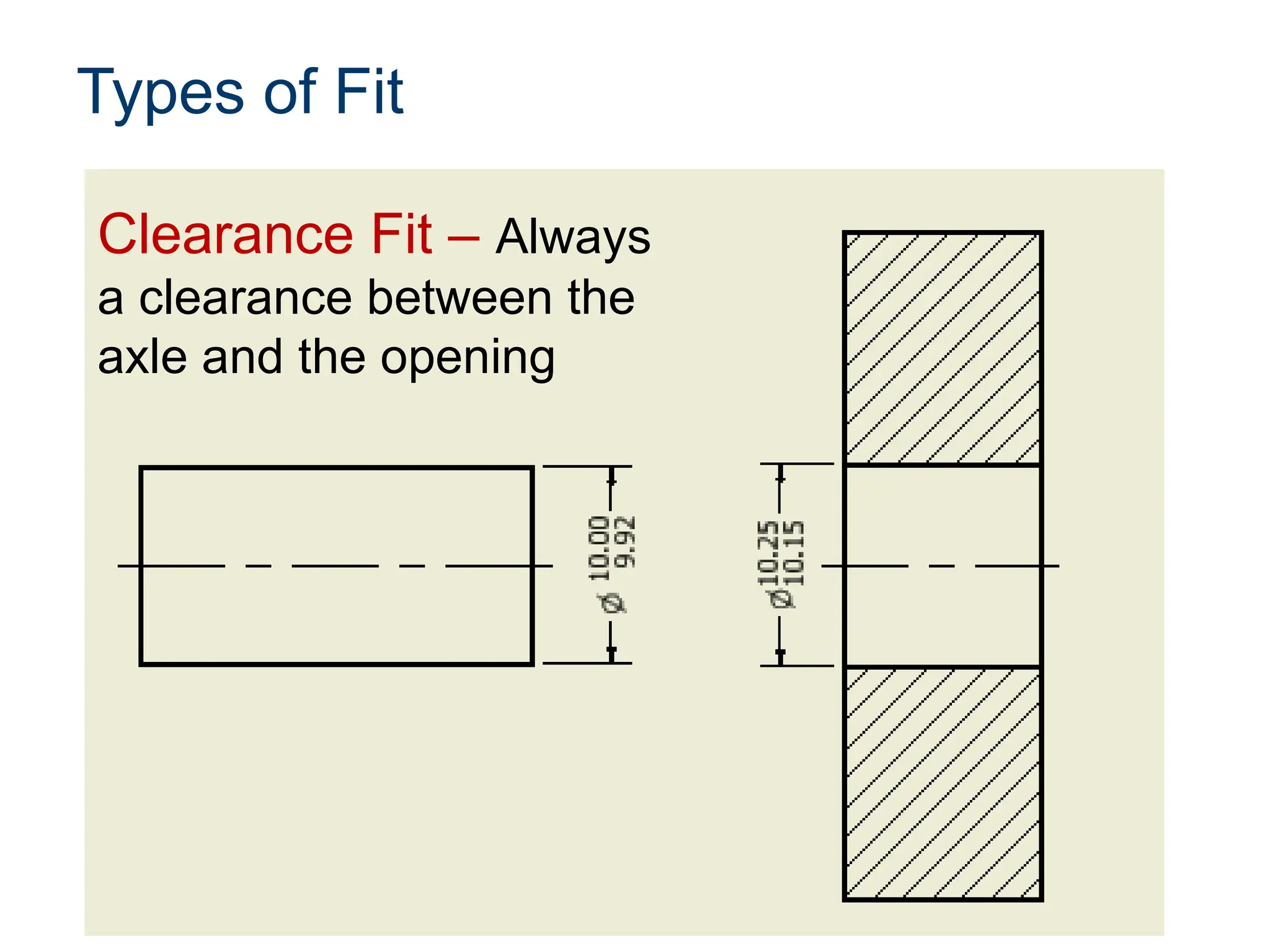

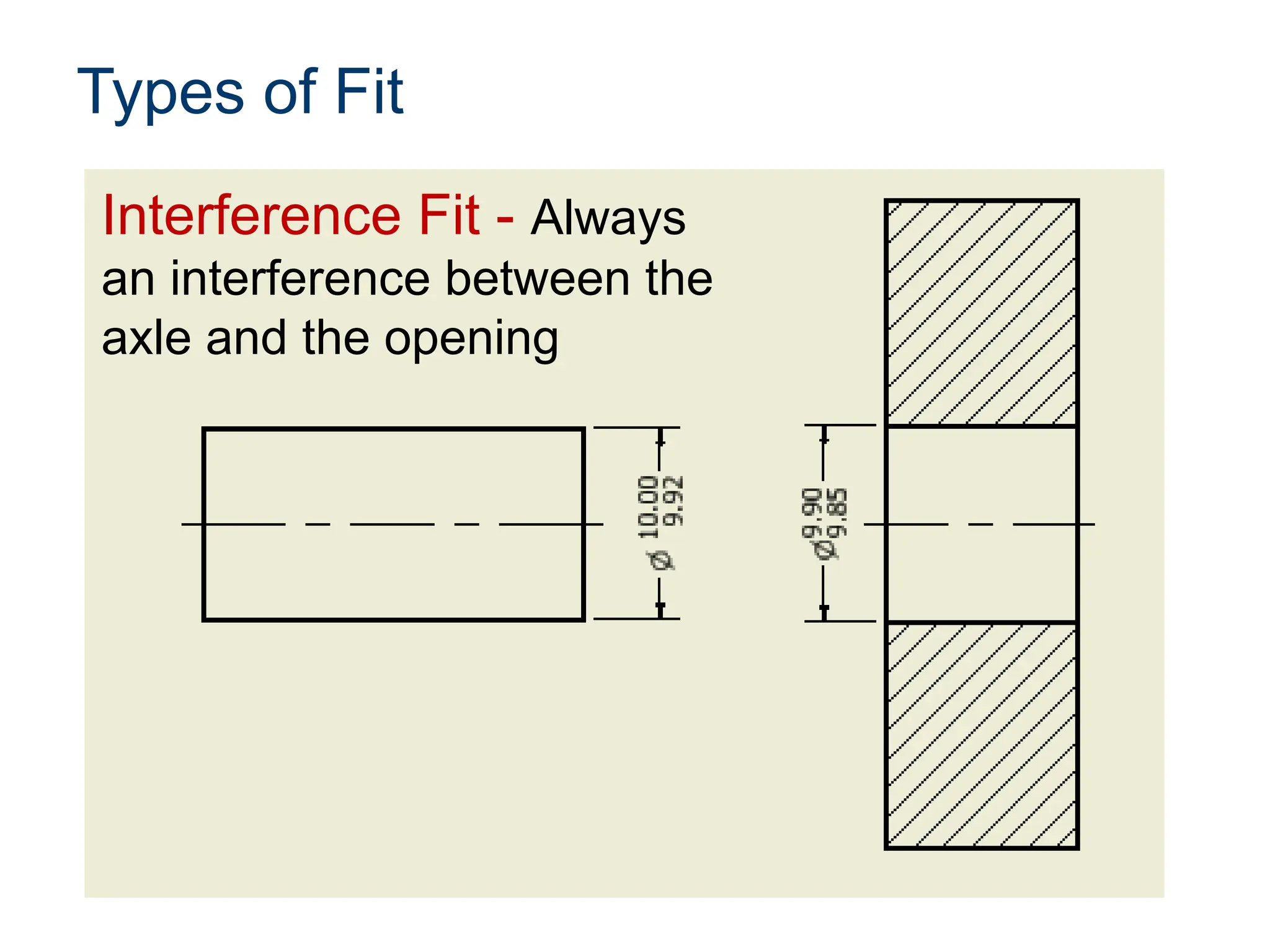

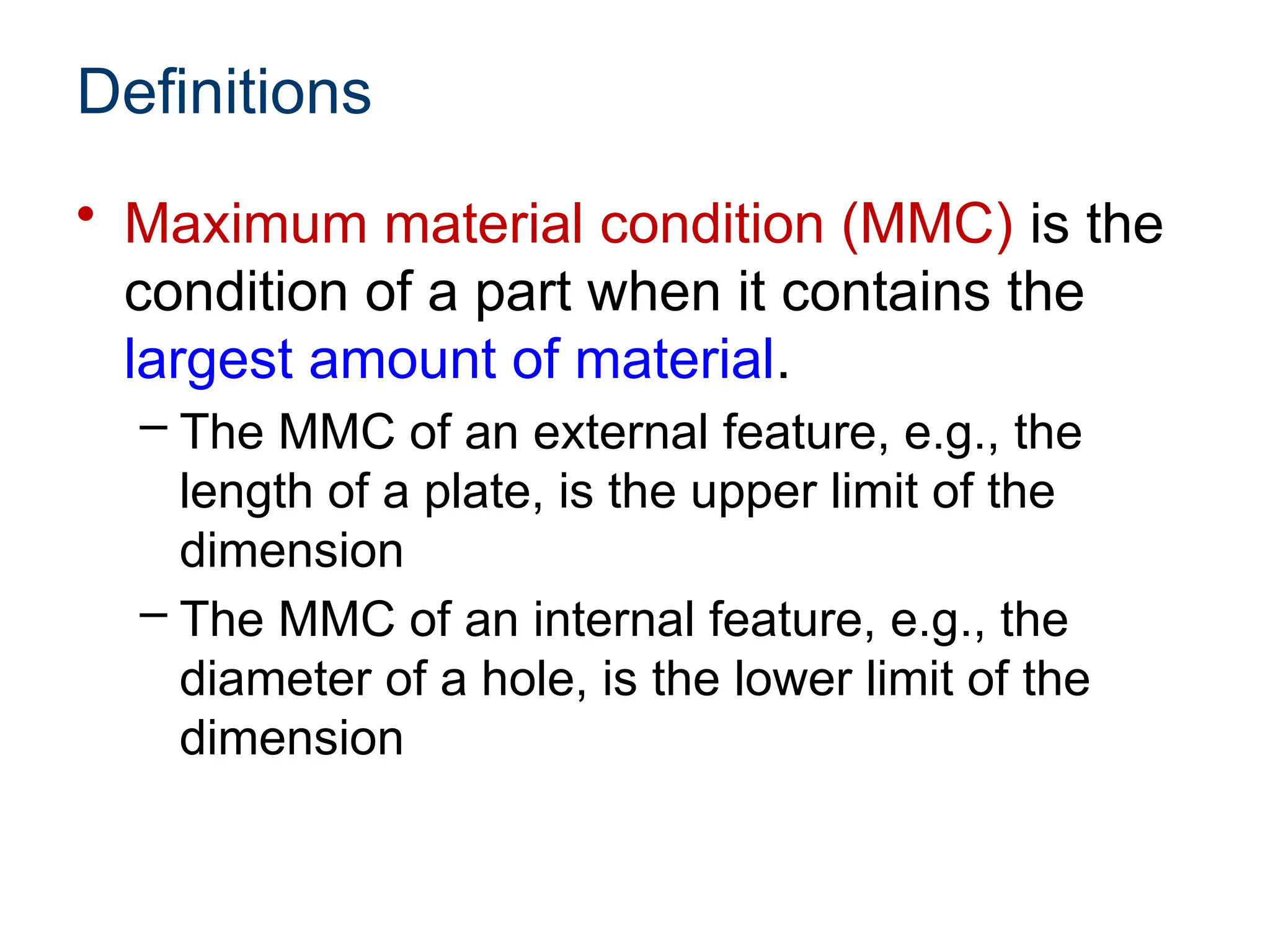

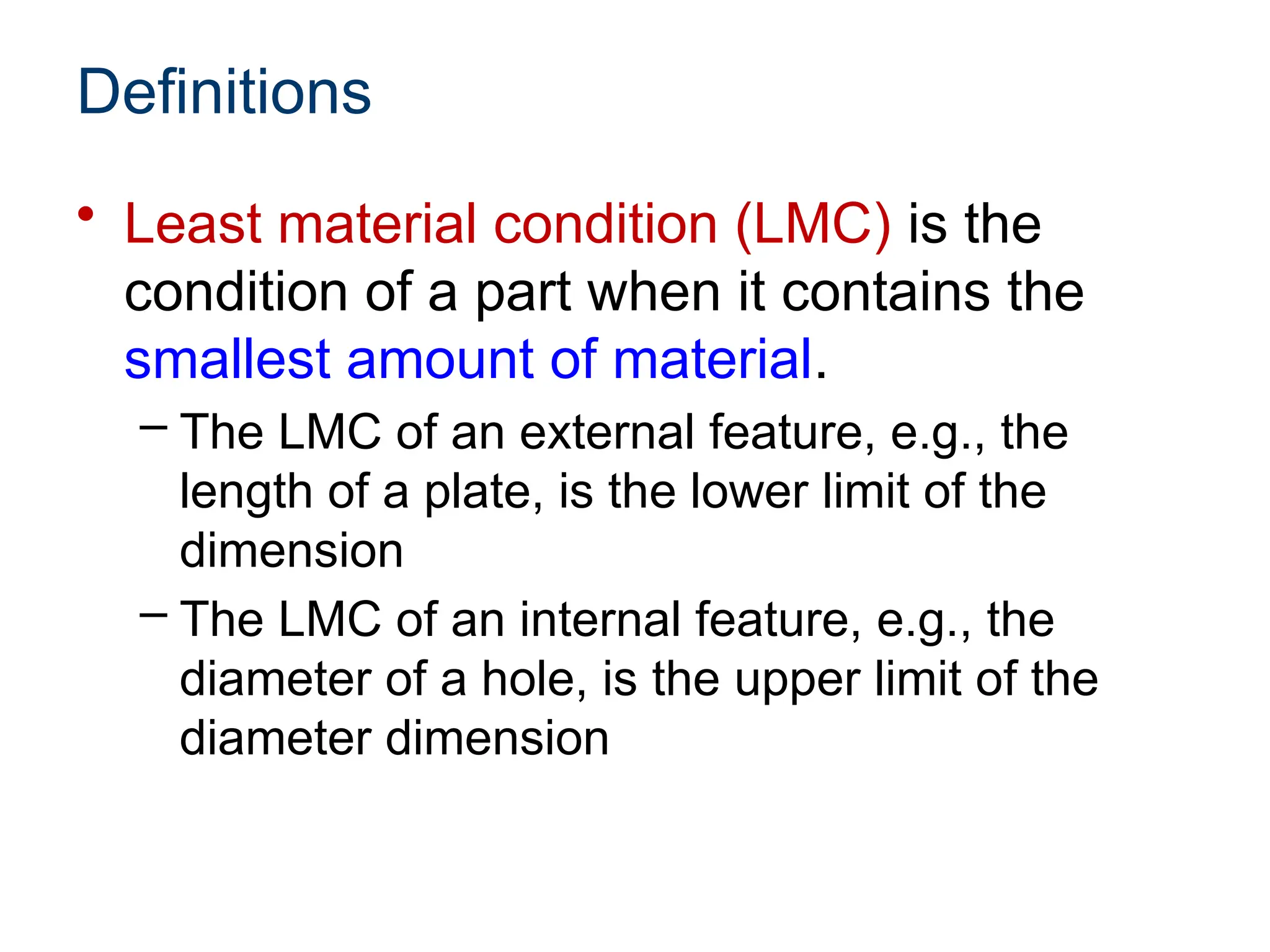

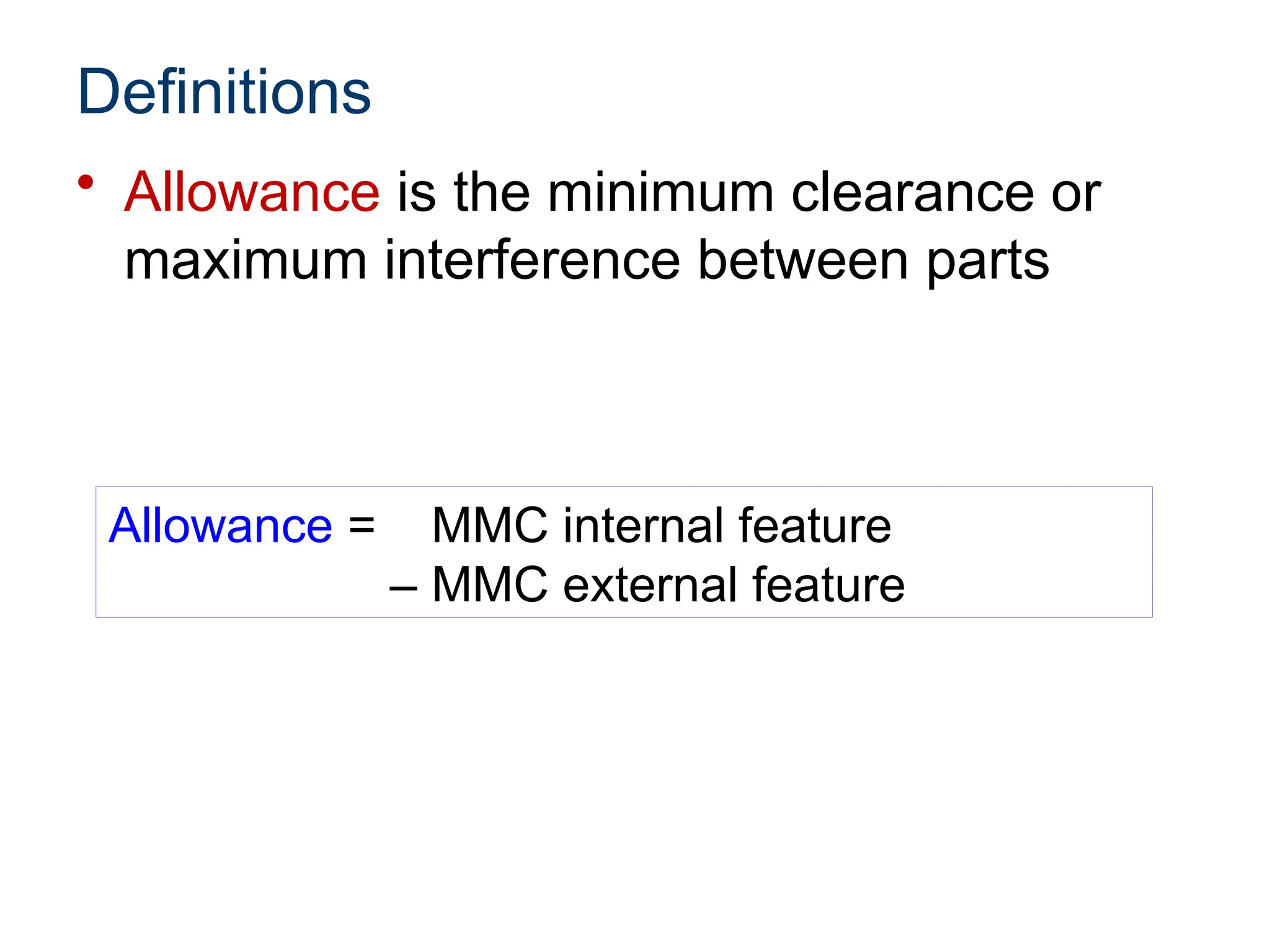

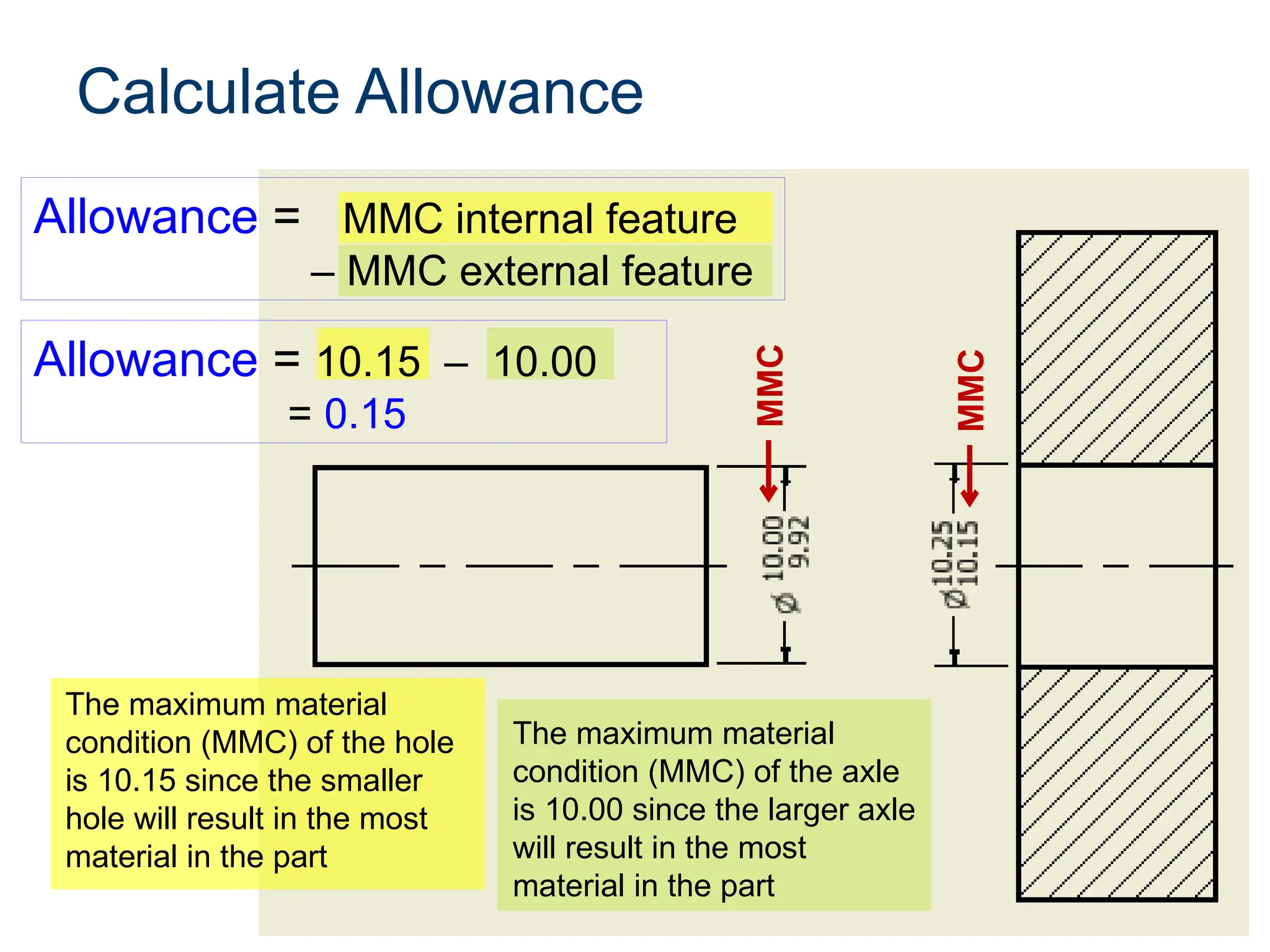

The document discusses the importance of tolerances in manufacturing, highlighting how variation is inevitable and tolerances control this variation in parts, particularly in assemblies for functionality and cost considerations. It explains different types of tolerances such as limit dimensions, bilateral, and unilateral tolerances, alongside definitions like maximum and least material conditions. General tolerances are addressed as well as concepts like fit types and allowances, emphasizing the need for appropriate specifications to avoid unnecessary costs and ensure proper part function.