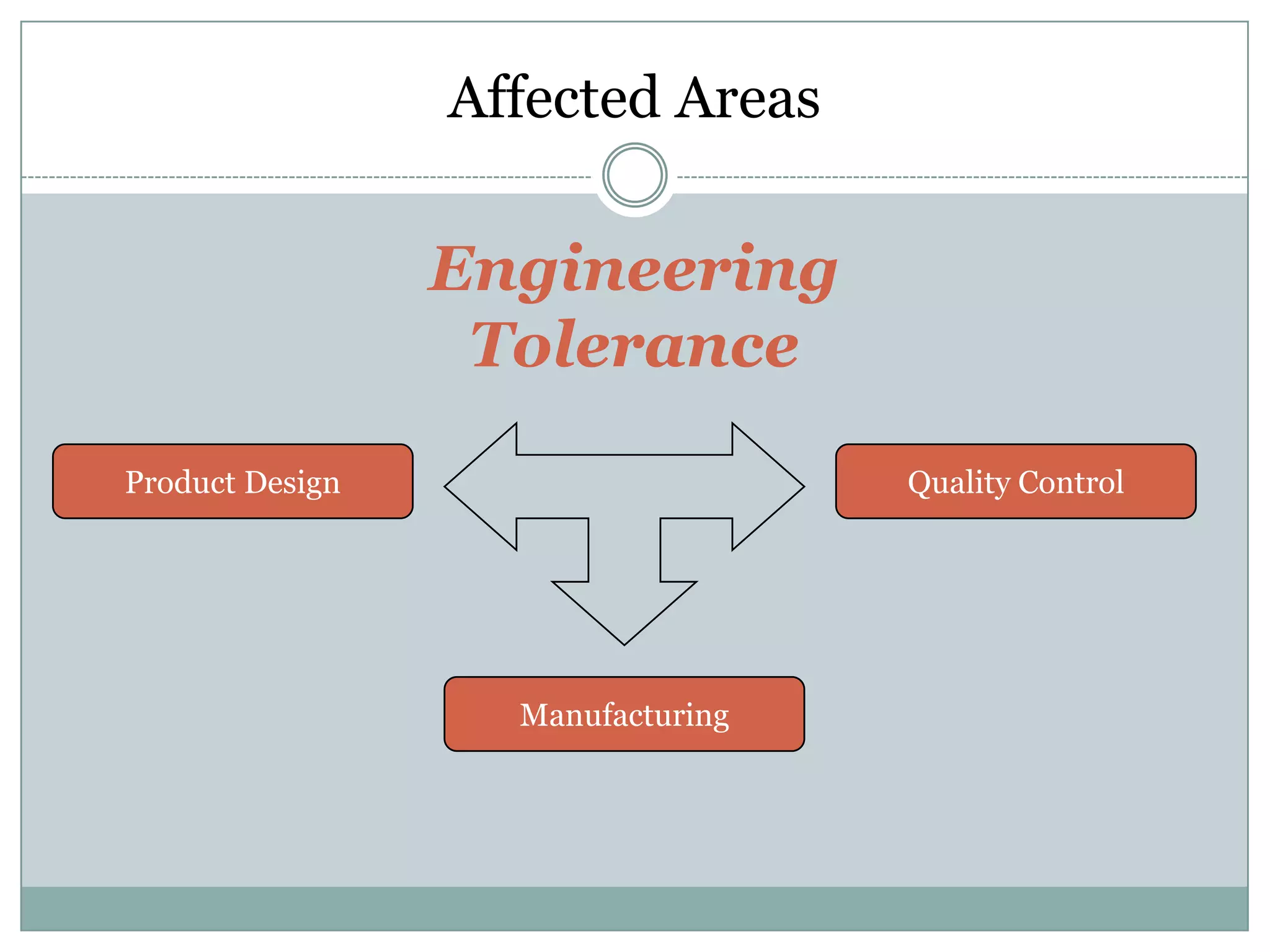

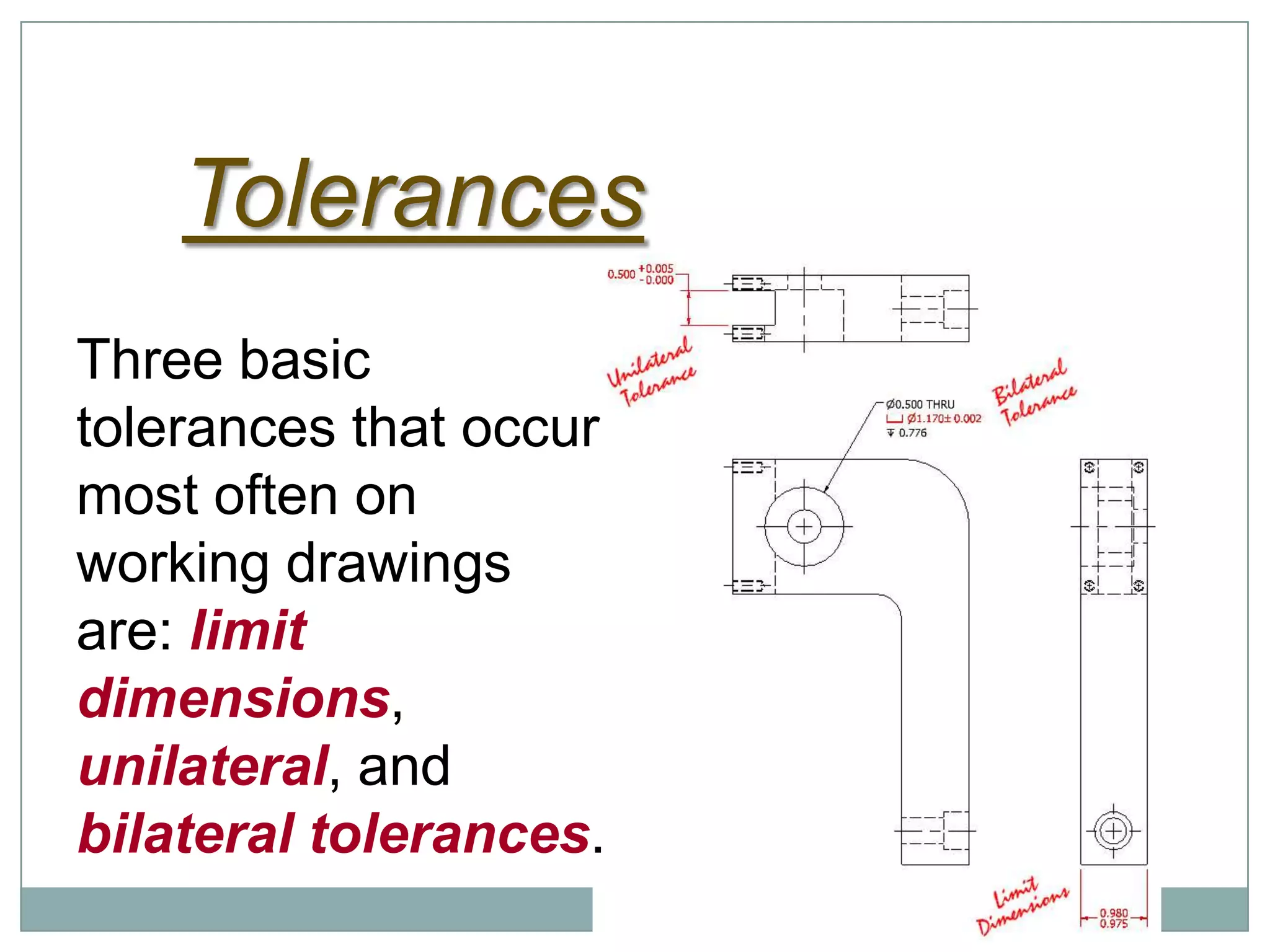

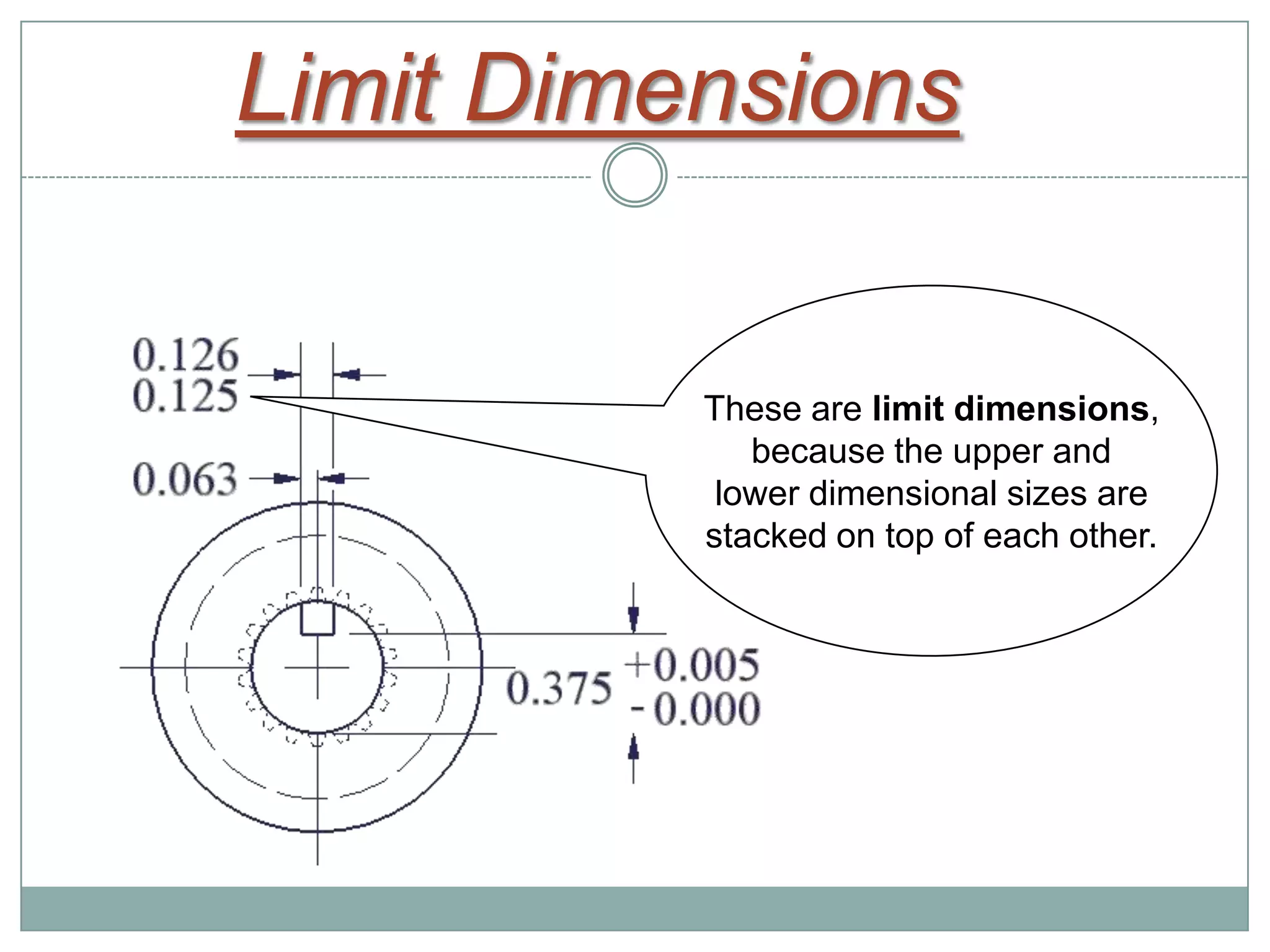

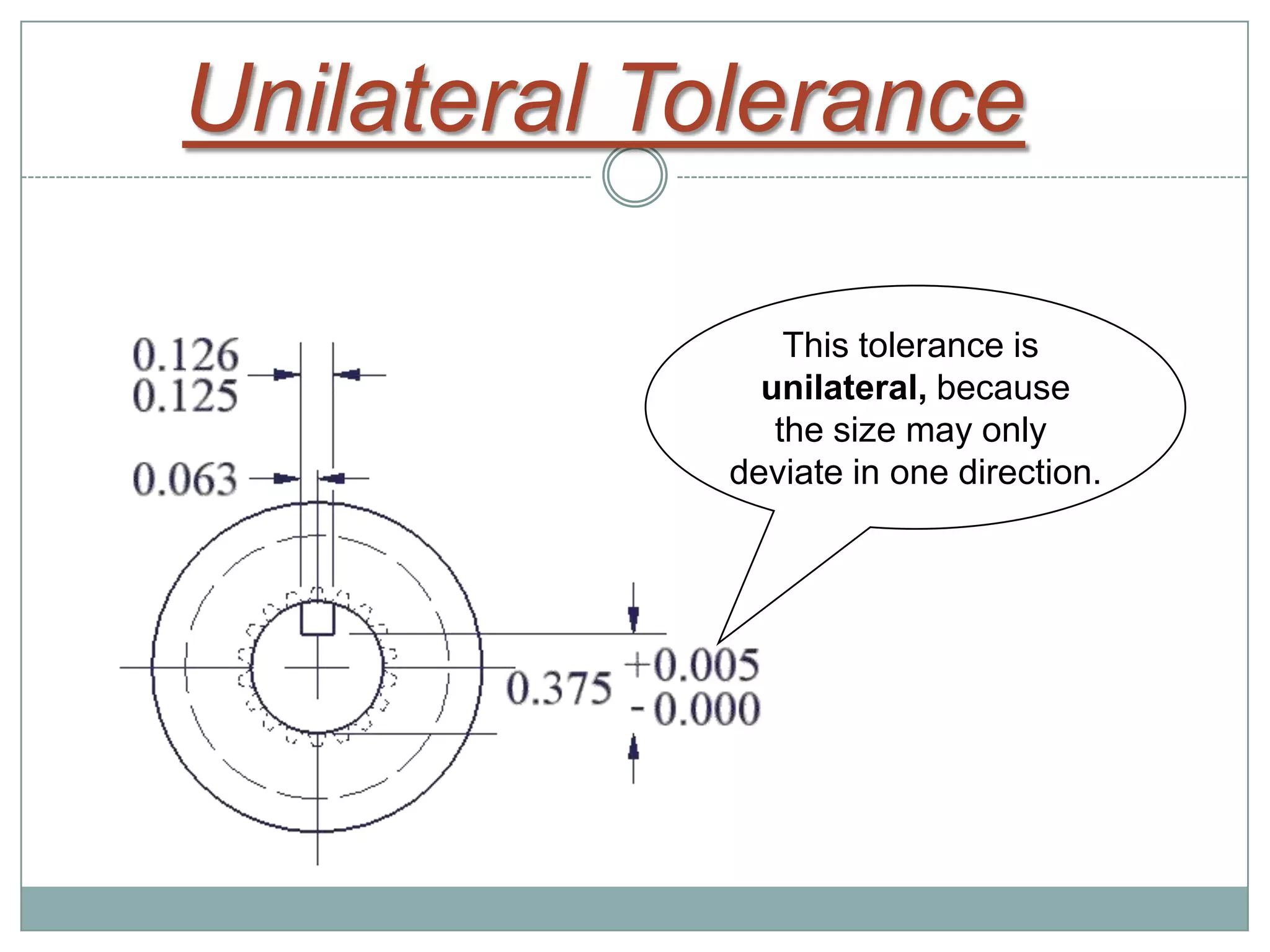

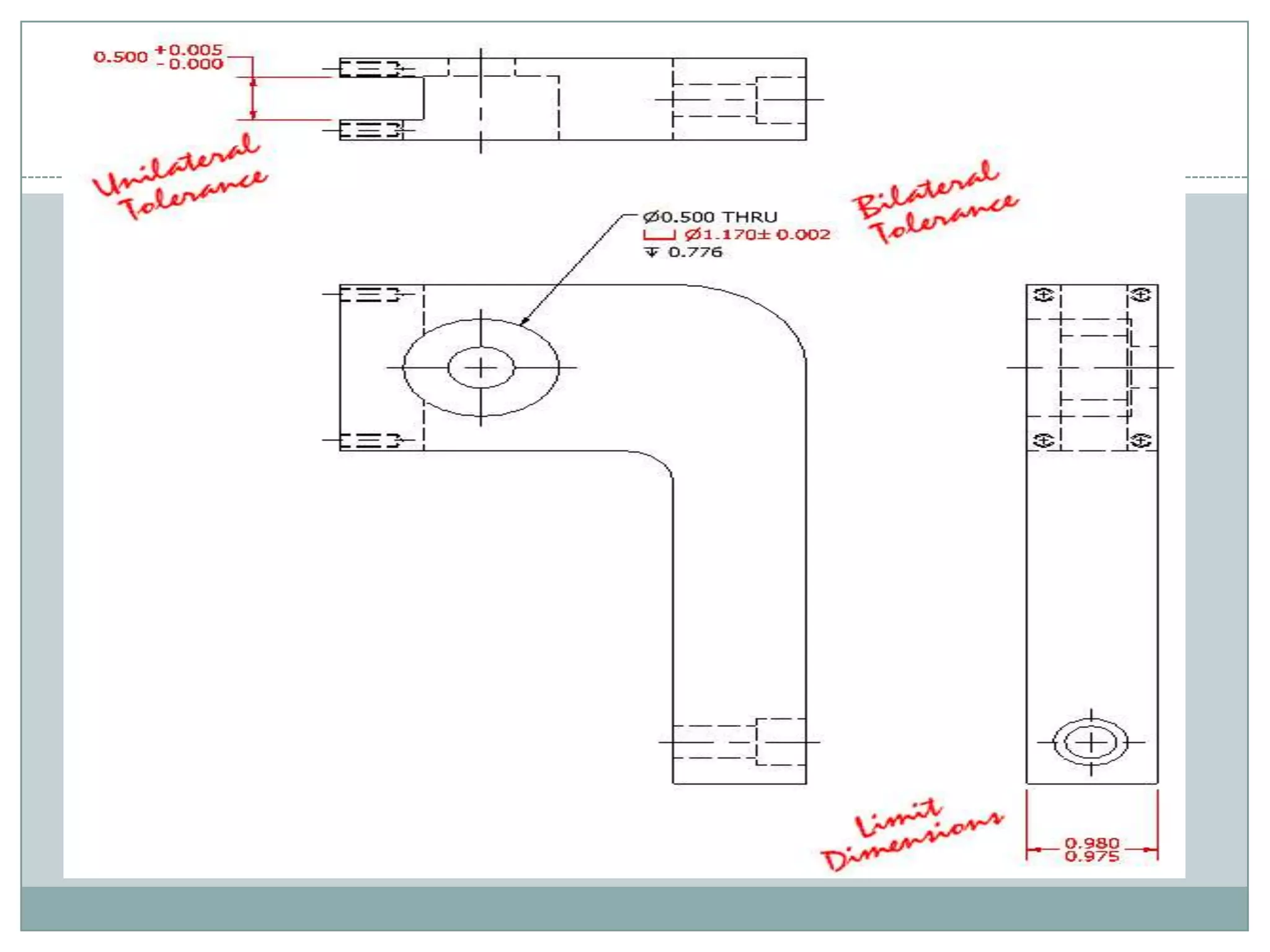

The document discusses tolerances and allowances in manufacturing. It defines tolerance as the acceptable variation from a nominal dimension, with three common types being limit, unilateral, and bilateral tolerances. Allowance is defined as a planned deviation from nominal to account for dimensional changes during future manufacturing processes, such as grinding or heat treating. The document explains that tolerances and allowances are important for interchangeable parts, product design, quality control, and manufacturing efficiency.