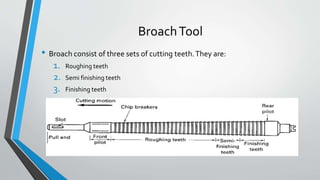

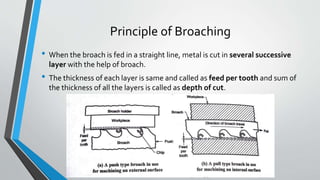

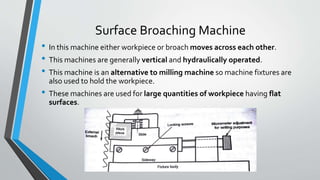

Broaching is a machining process where a broach tool with multiple cutting teeth is pushed or pulled through a workpiece to cut it into the desired shape. Broaching provides good dimensional accuracy and surface finish. There are different types of broaching machines like horizontal, vertical pull, continuous, and rotary table machines. Broaching is used to manufacture precision components like bearing caps, gears, and splines. It provides interchangeability but the initial costs of broaches and machines are high.