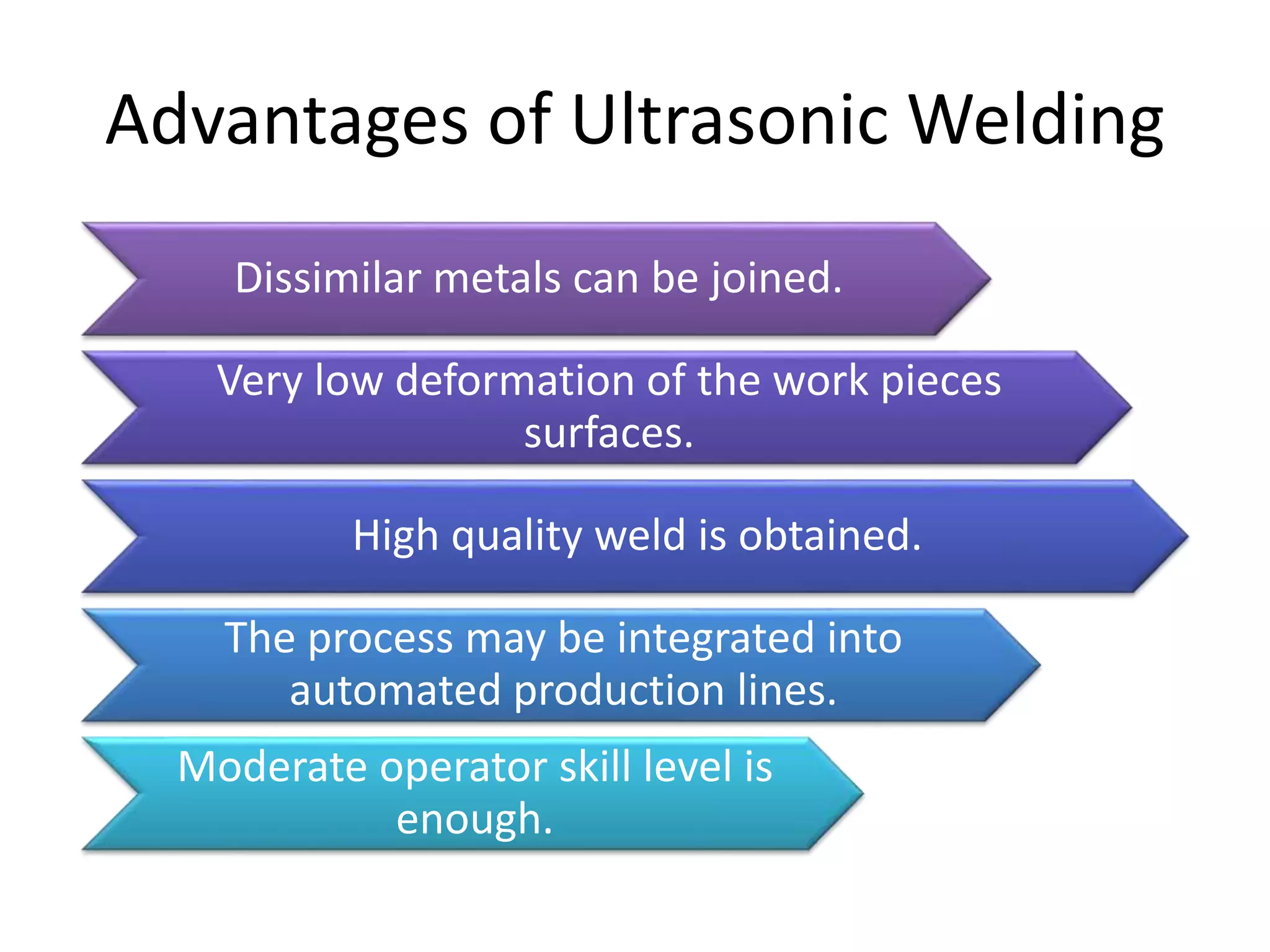

Solid state welding involves joining materials without melting them using pressure and heat below their melting points. There are several types of solid state welding including forge welding, cold welding, friction welding, explosive welding, diffusion welding, and ultrasonic welding. Each type uses different techniques like pressure, vibration, or explosive force to join materials like steel, aluminum, and titanium without melting them. Solid state welding has advantages like avoiding defects from melting and ability to join dissimilar metals, but also has disadvantages like requiring expensive equipment or time-consuming processes.