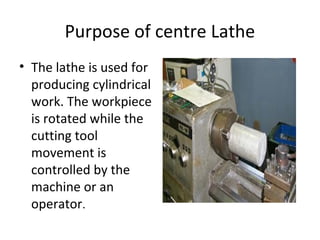

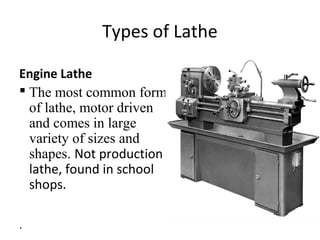

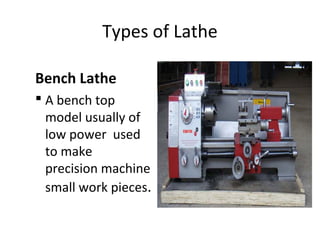

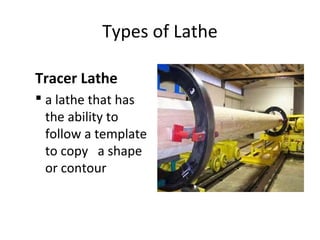

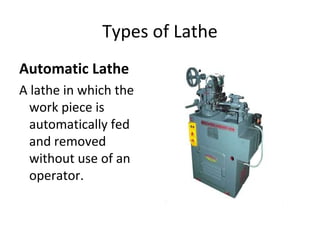

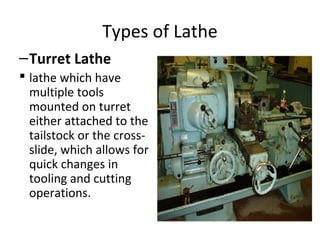

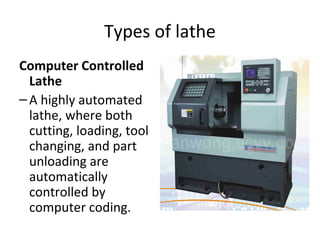

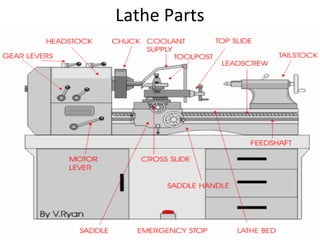

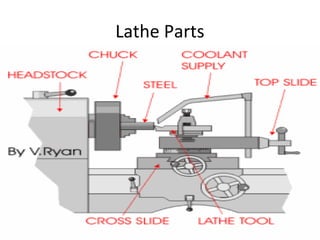

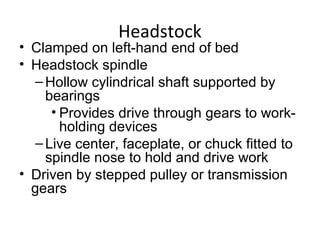

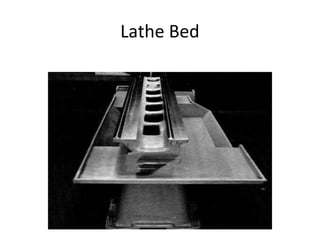

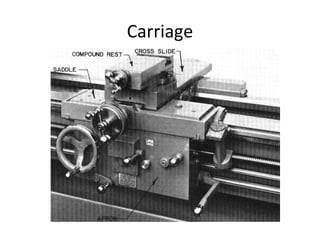

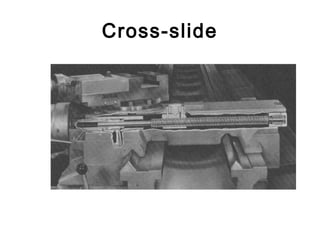

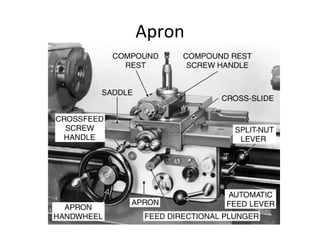

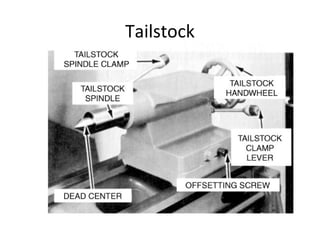

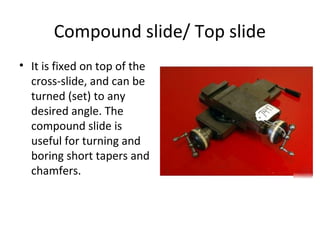

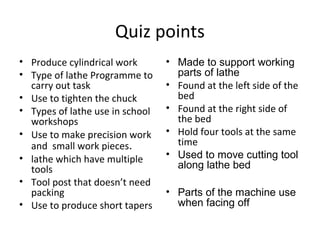

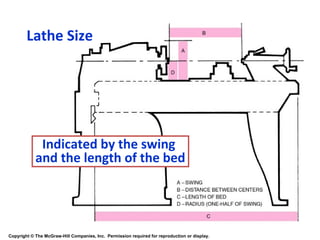

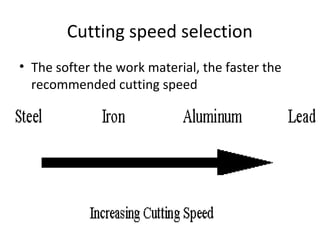

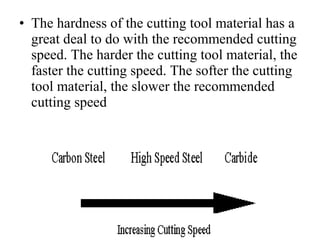

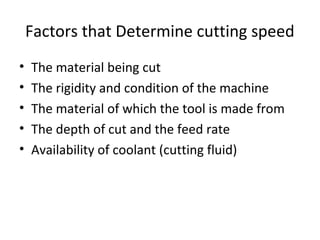

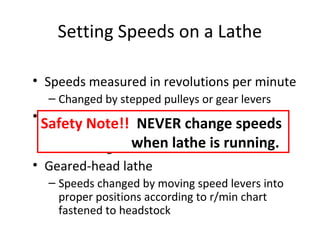

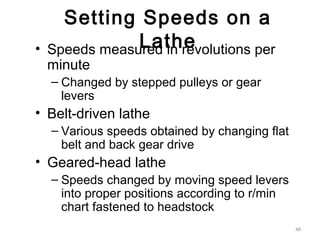

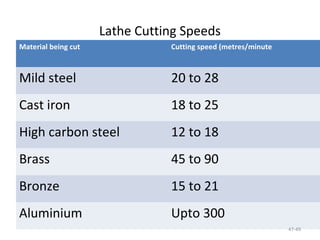

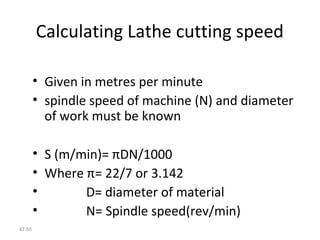

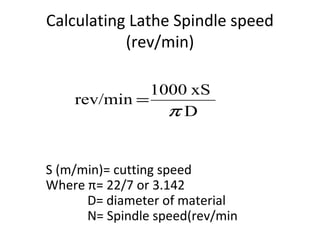

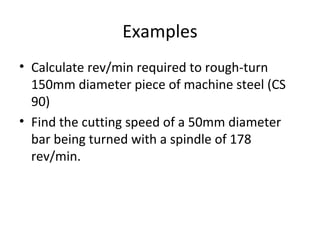

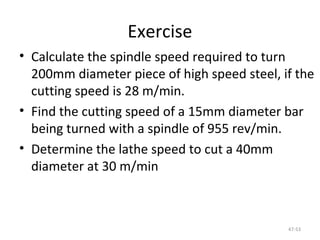

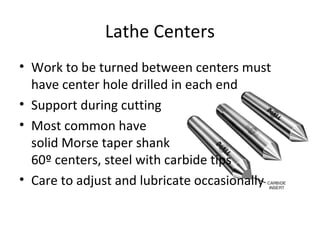

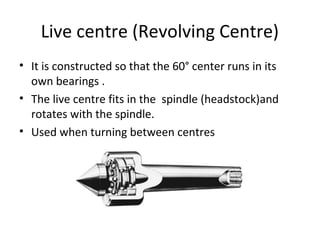

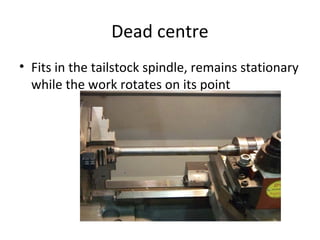

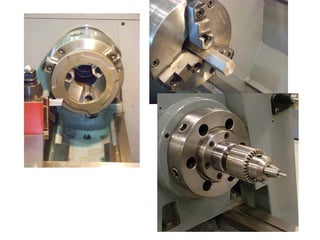

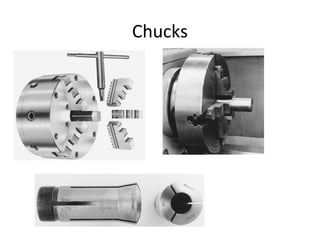

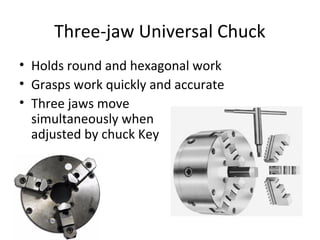

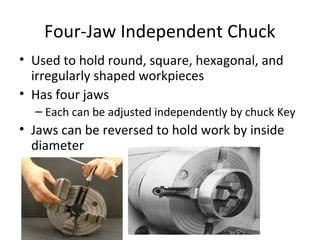

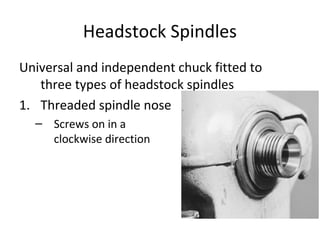

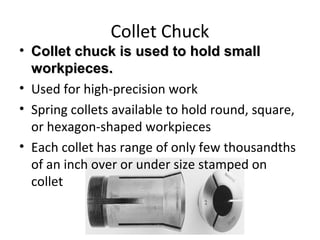

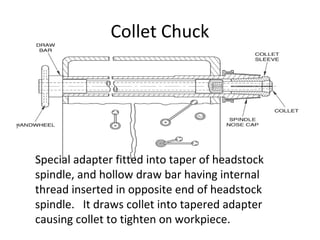

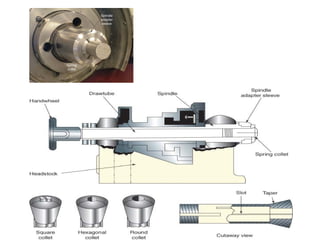

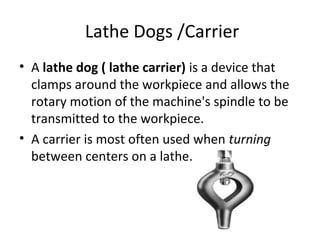

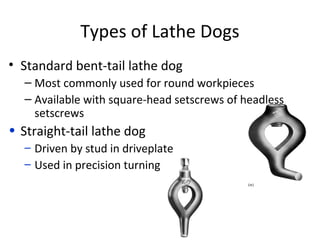

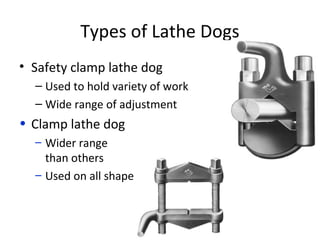

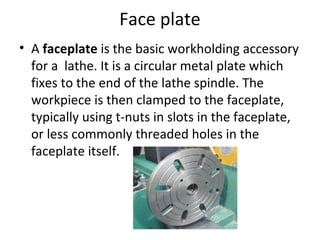

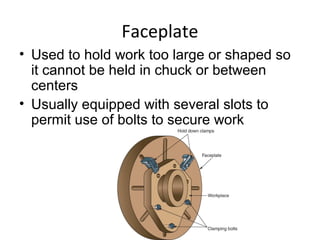

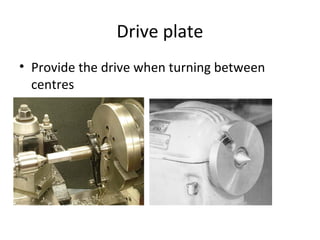

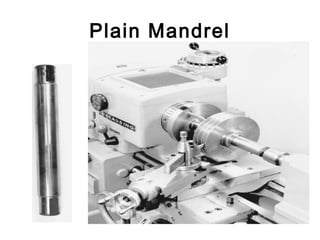

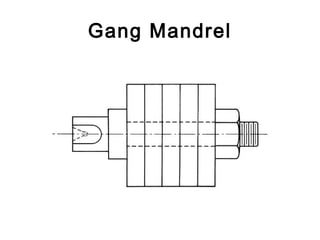

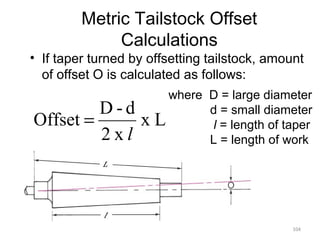

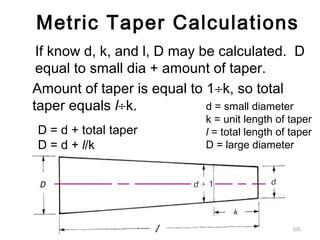

This document provides information about mechanical engineering and the centre lathe. It discusses the main parts and functions of the lathe, including the headstock, bed, carriage, cross-slide, apron, tailstock, tool post, and quick-change gearbox. It also covers lathe safety, types of lathes, cutting speeds, lathe accessories such as centers, chucks, faceplates, and work holding methods. The objectives are to identify lathe parts and their purposes, discuss safety procedures, calculate cutting speeds, and describe various lathe accessories.