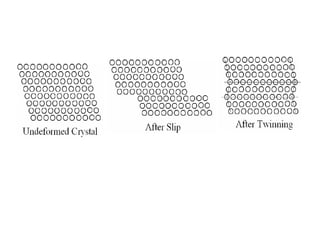

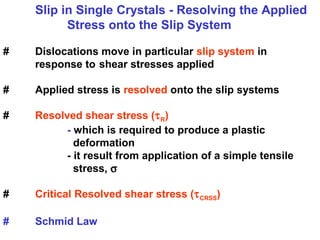

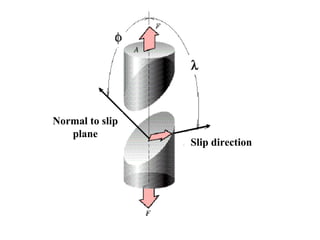

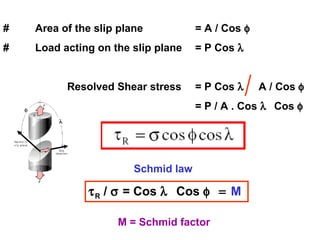

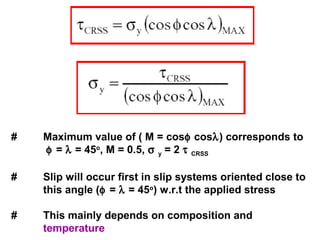

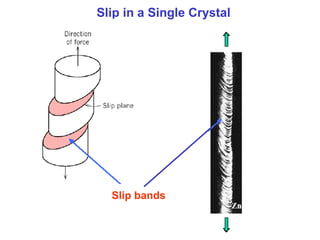

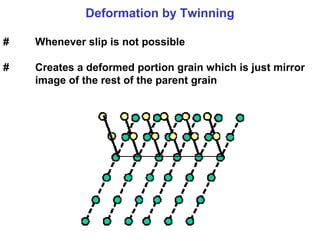

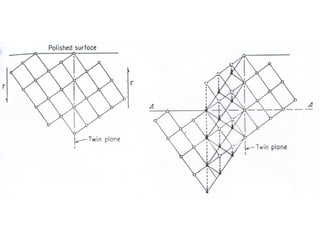

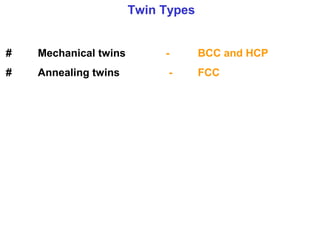

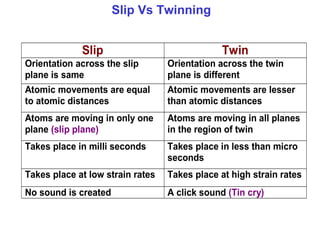

This document discusses two mechanisms of plastic deformation in metals: slip and twinning. Slip involves the sliding of crystal blocks along crystallographic planes called slip planes, analogous to pushing cards in a deck. Twinning results in a mirrored orientation of a crystal portion. Slip is the primary deformation mechanism and occurs when shear stress exceeds a critical value, following Schmid's law. Twinning occurs when slip is not possible and results in a deformed mirrored grain. The document compares the characteristics and conditions of slip versus twinning.