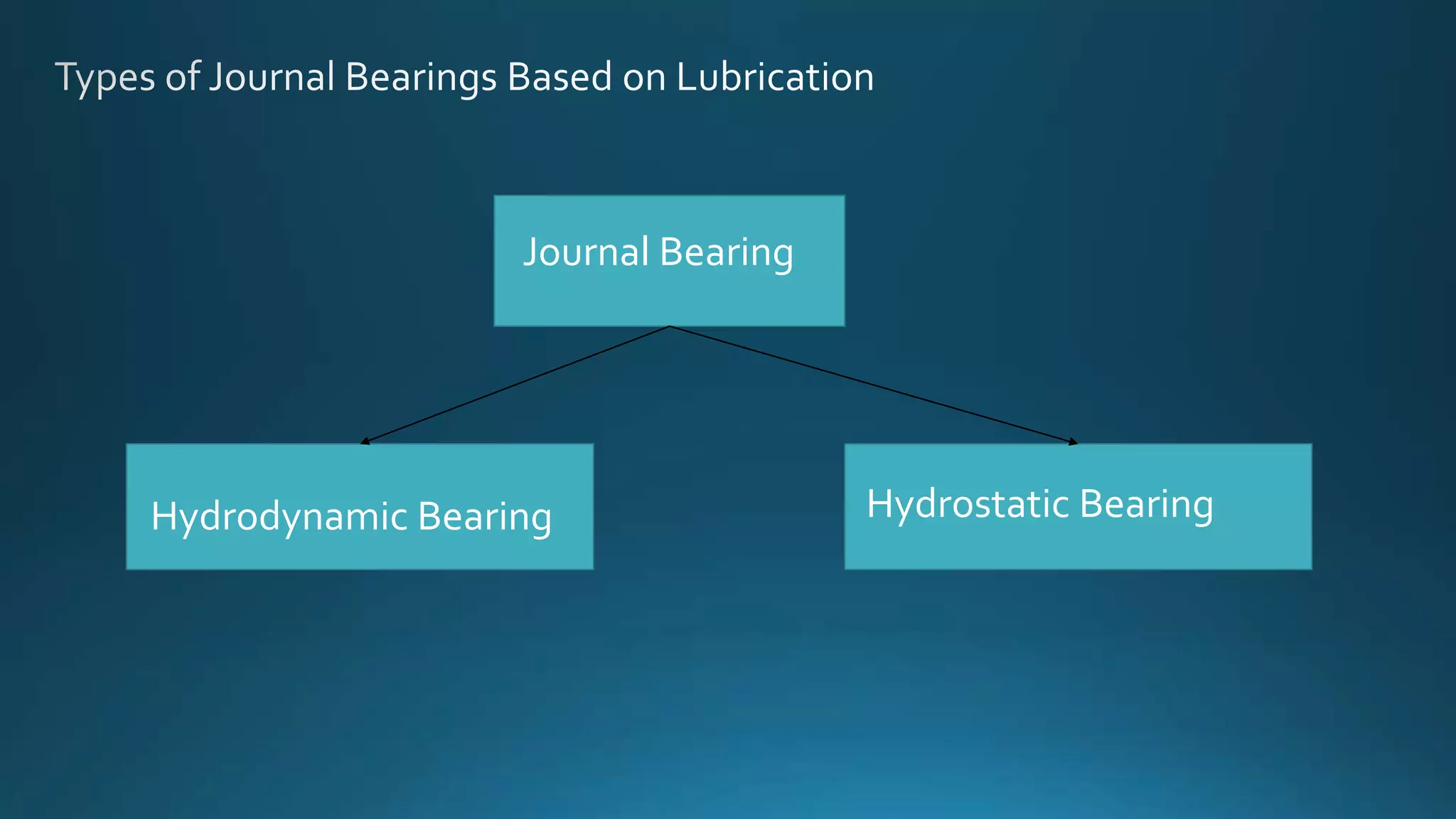

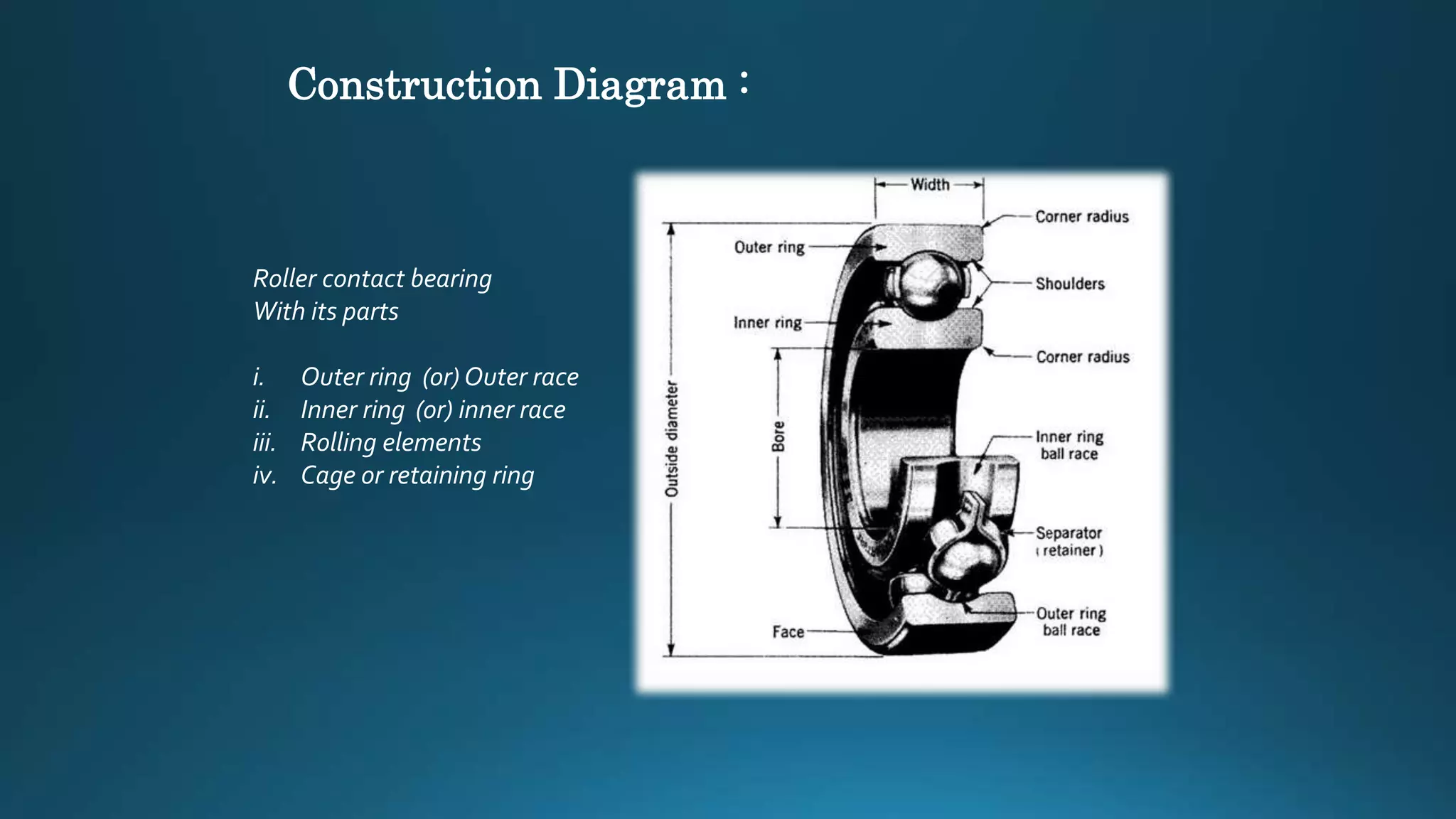

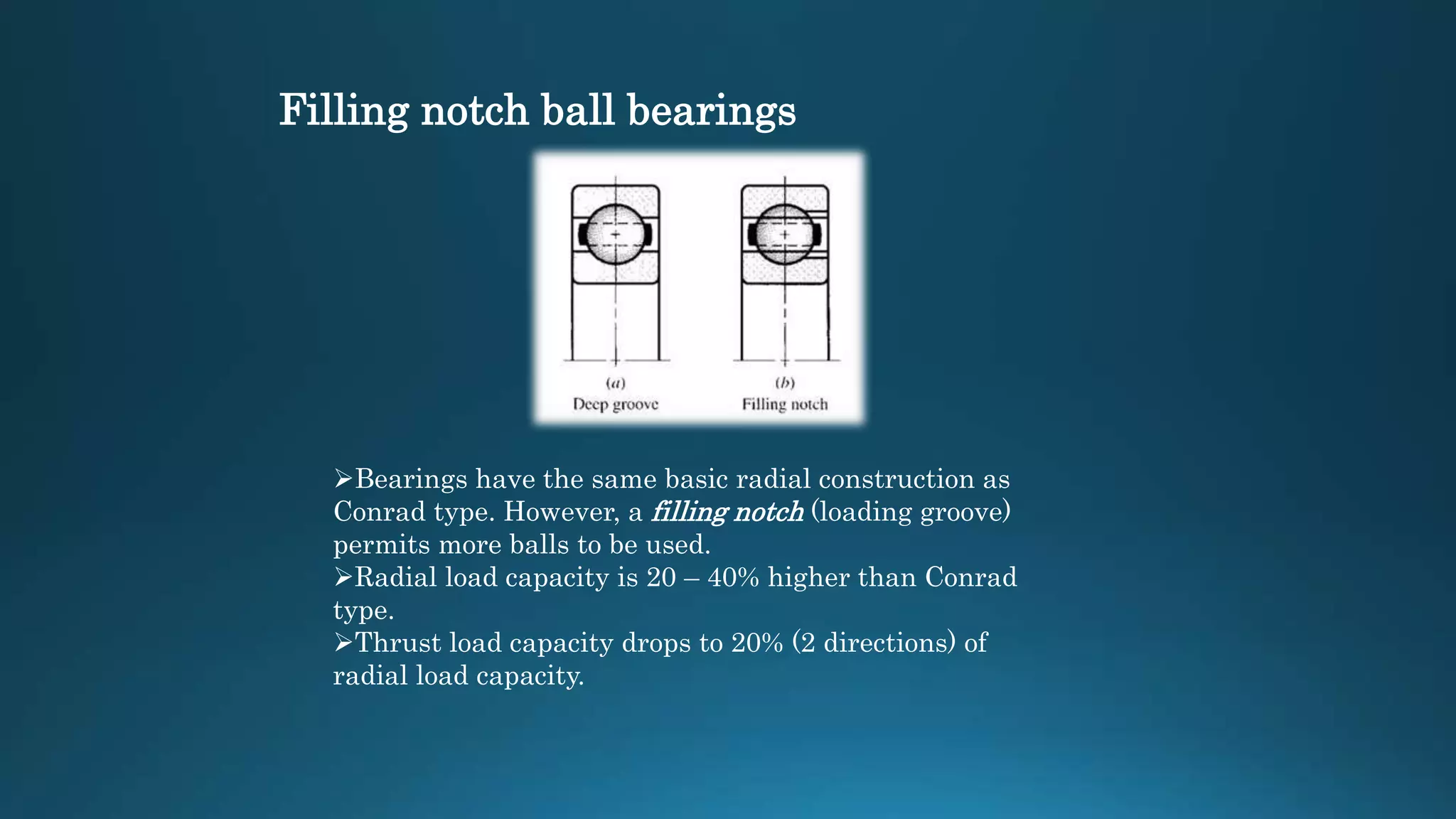

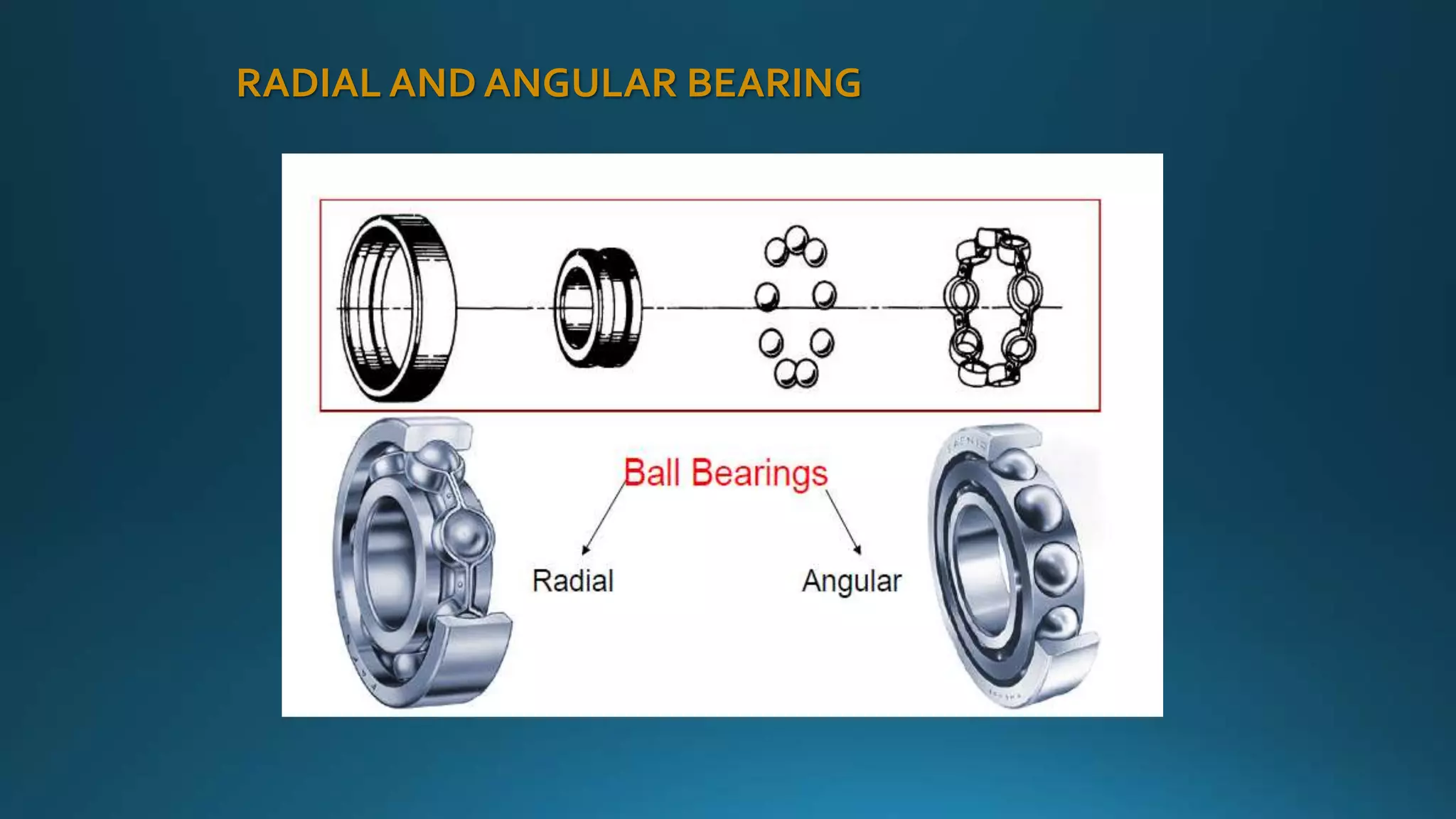

This document discusses different types of bearings used in mechanical engineering. It describes bearings as machine components that support another element and allow relative motion while carrying a load. There are two main types - sliding contact bearings and rolling contact bearings. Rolling contact bearings, also called anti-friction bearings, use balls or rollers between elements and have lower coefficients of friction than sliding contact bearings. The document further details types of rolling contact bearings like ball bearings, roller bearings, and their construction and applications.