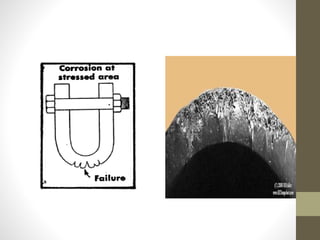

Stress corrosion cracking is the failure of a normally ductile metal caused by the combined effect of tensile stress and a corrosive environment. Three factors are required for stress corrosion cracking to occur: a susceptible material, a tensile stress (either applied or residual), and a corrosive environment. Stress corrosion cracking leads to the formation of cracks that propagate in the material over time and eventually result in sudden brittle fracture.