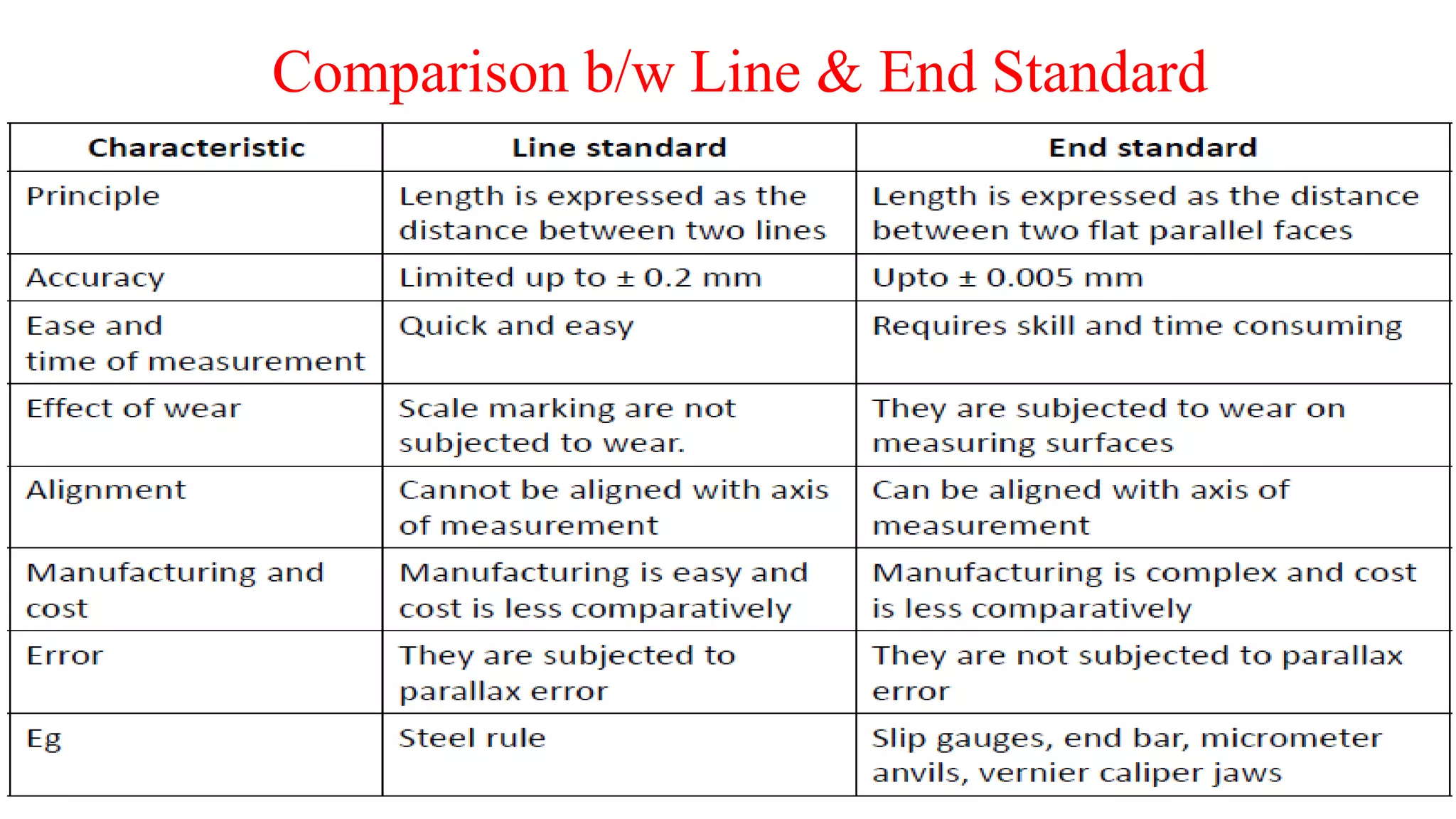

Line standards and end standards are two categories of instruments used to directly measure linear dimensions.

A line standard measures the distance between the centers of two engraved lines, such as a ruler. It allows for quick measurements over a wide range but lacks precision due to line thickness and susceptibility to parallax errors.

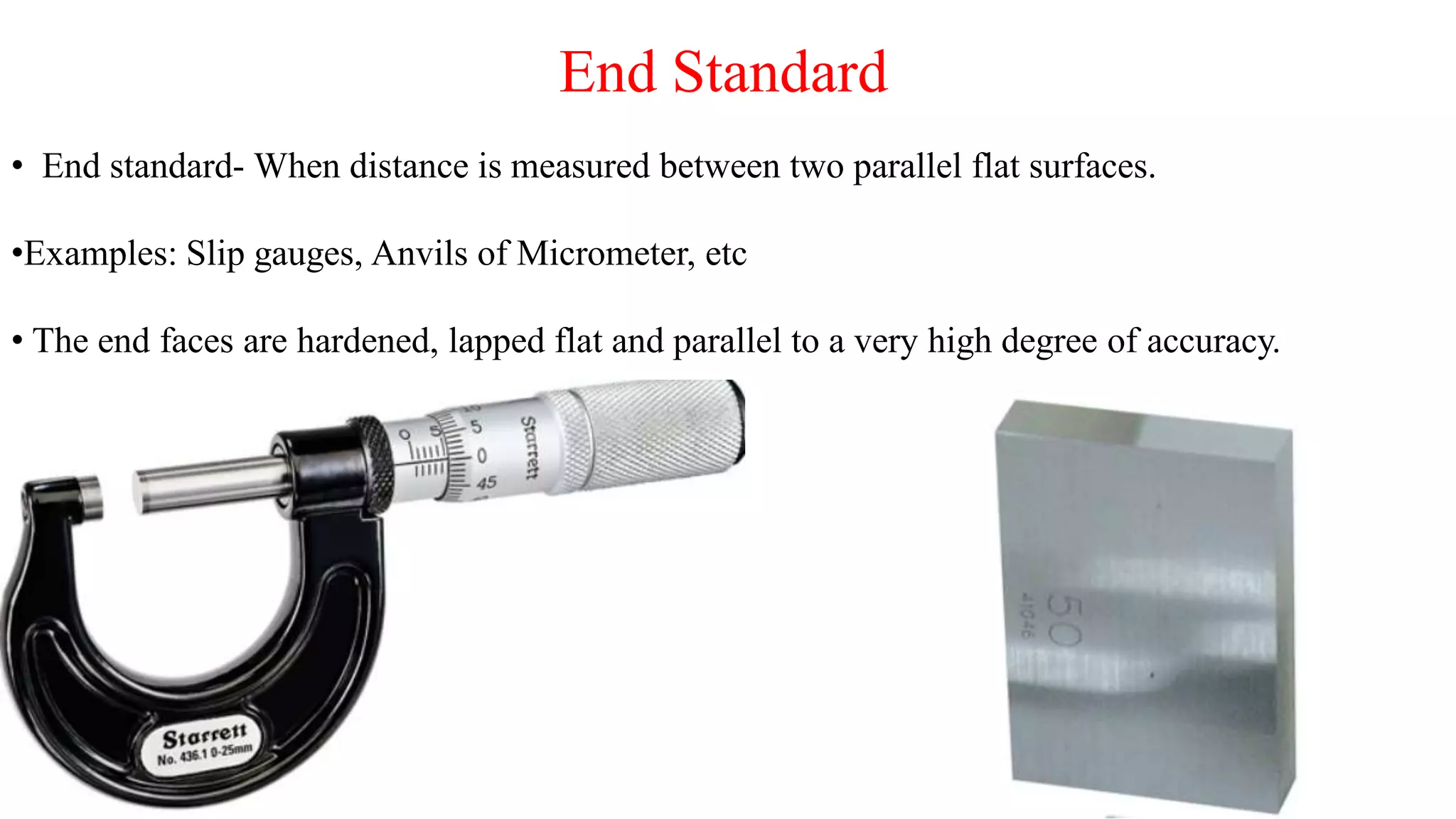

An end standard measures the distance between two parallel flat surfaces, such as slip gauges or a micrometer anvil. It provides highly accurate measurements of close tolerances but is more time-consuming and the faces can wear over time. End standards have a built-in datum for alignment and are not subject to parallax.