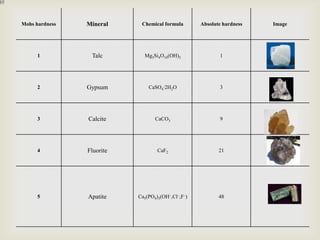

The document discusses shore hardness testing, which measures the resistance of materials to indentation. Shore hardness is measured using a durometer indenter that penetrates the sample, with higher numbers indicating greater resistance. The shore scale has two types - Shore A for softer rubbers and Shore D for harder materials. Shore hardness provides an empirical measure of indentation resistance but does not predict other material properties. Mohs hardness characterizes scratch resistance and was created by Friedrich Mohs using minerals to demonstrate increasing hardness.