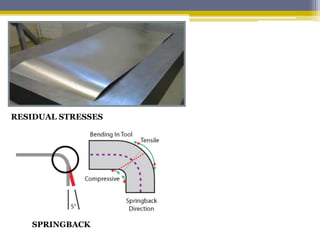

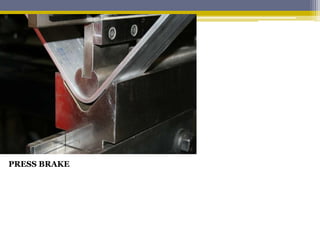

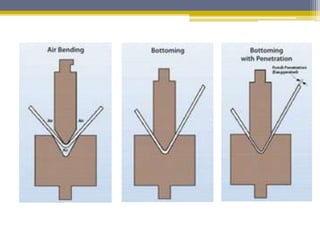

This document discusses various sheet forming techniques used to produce parts from sheet metal. It covers factors that must be considered like elongation and anisotropy. Specific techniques covered include deep drawing, bending, press braking, and shearing. Deep drawing involves stretching and drawing sheet metal into cylindrical or box shapes using a punch and die. Bending can be done with presses, rolls, or press brakes and factors like bend radius and anisotropy are important. Shearing uses punches and dies to cut blanks from sheet metal.