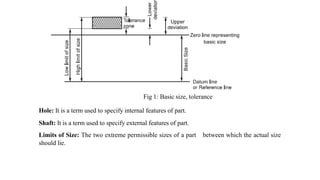

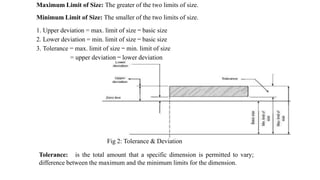

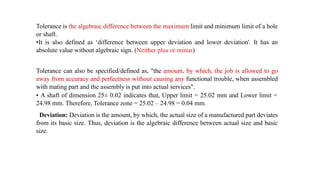

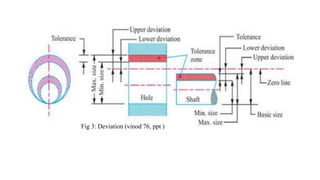

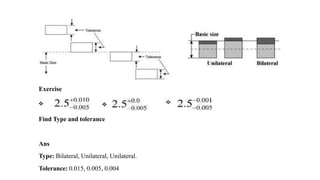

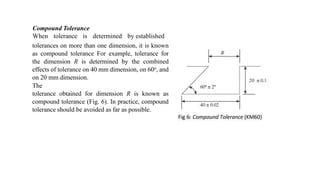

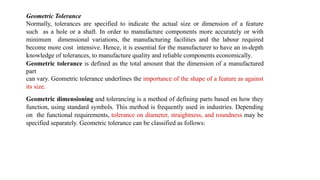

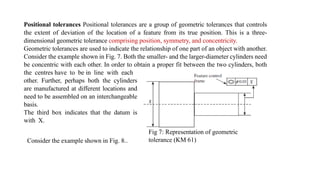

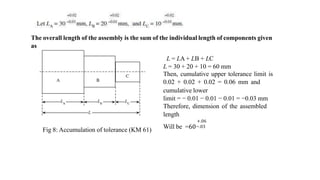

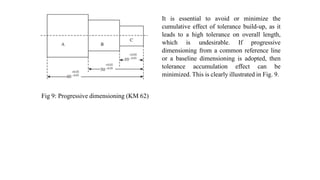

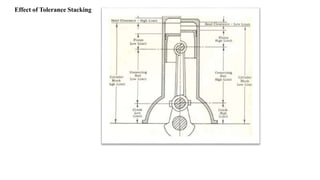

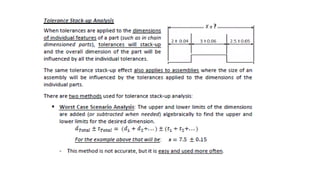

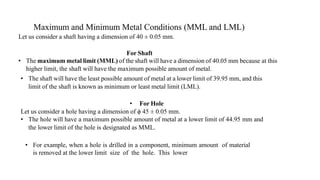

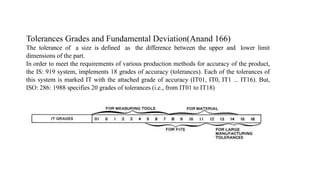

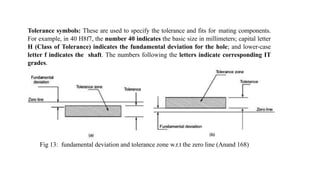

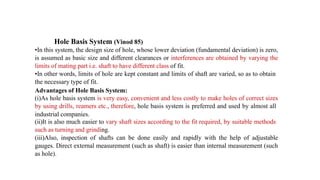

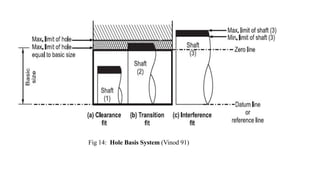

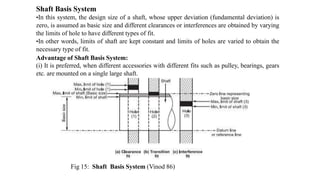

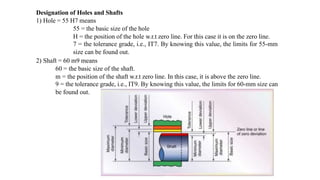

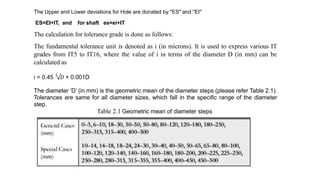

The document discusses limits, fits, and tolerances in manufacturing. It defines key terms like basic size, tolerance, deviation, allowance and different types of fits and tolerances. Tolerance is specified to indicate the permissible variation in a part's actual size from its nominal dimensions. Allowance refers to the intentional difference between mating features to achieve a desired fit. The document also discusses principles of interchangeability and how tolerances are accumulated in an assembly. Maximizing interchangeability requires minimizing the effects of tolerance stacking.

![PRINCIPLE OF INTERCHANGEABILITY

Modern production techniques require that a complete product be broken into various component

parts so that the production of each part becomes an independent process, leading to

specialization.

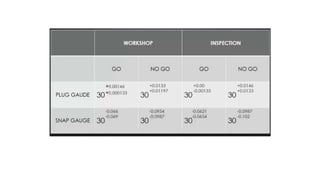

When interchangeable manufacture is adopted, any one component selected at random should

assemble with any other arbitrarily chosen mating component. In order to assemble with a

predetermined fit, the dimensions of the components must be confined within the permissible

tolerance limits. By interchangeable assembly, we mean that identical components, manufactured

by different operators, using different machine tools and under different environmental

conditions, can be assembled and replaced without any further modification during the assembly

stage and without affecting the functioning of the component when assembled.

When one component assembles properly (and which

satisfies the functionality aspect of the assembly/product)

with any mating component, both chosen at random, then it

is known as interchangeability [Anand.150]](https://image.slidesharecdn.com/module2partilimitsfitsandtolerances-220311142811/85/Module-2-part-i-limits-fits-and-tolerances-3-320.jpg)

![For example, consider the assembly of a shaft and a part with a hole. The two mating parts

are produced in bulk, say 1000 each. By interchangeable assembly any shaft chosen

randomly should assemble with any part with a hole selected at random, providing the

desired fit.

Another major advantage of interchangeability is the ease with which replacement of

defective or worn-out parts is carried out, resulting in reduced maintenance cost.

In order to achieve interchangeability, certain standards need to be followed, based on which

interchangeability can be categorized into two types—universal interchangeability and local

interchangeability.

When the parts that are manufactured at different locations are randomly chosen for assembly, it

is known as universal interchangeability. To achieve universal interchangeability, it is desirable

that common standards be followed by all and the standards used at various manufacturing

locations be traceable to international standards[Km51].

When the parts that are manufactured at the same manufacturing unit are randomly drawn for

assembly, it is referred to as local interchangeability. In this case, local standards are followed.](https://image.slidesharecdn.com/module2partilimitsfitsandtolerances-220311142811/85/Module-2-part-i-limits-fits-and-tolerances-4-320.jpg)

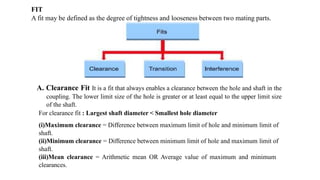

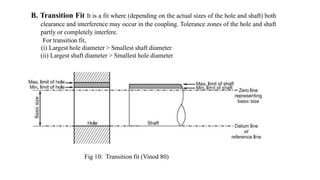

![(a)Wringing fit: It provides either zero interference or a clearance. It is employed, where

parts can be replaced without difficulty during minor repairs.

(b)Push fit: It provides small clearance. It is employed for parts that must be dis-assembled

during operation of a machine. For example: Changing gears etc.

C. Interference Fit It is a fit that always ensures some interference between the hole and

shaft in the coupling. The upper limit size of the hole is smaller or at least equal to the lower

limit size of the shaft.

Therefore, for Interference fit : Smallest shaft diameter > Largest hole diameter.

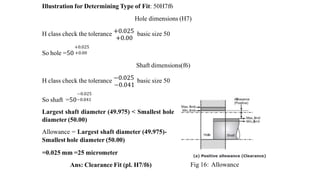

•In clearance fit, allowance is the minimum clearance, i.e. difference between minimum

size of hole and maximum size of shaft. It is referred as positive allowance. [Ref. Fig. 11(a)].

• In interference fit, allowance is the maximum interference, i.e. difference between

minimum size of hole and maximum size of shaft. It is referred as negative allowance. [Ref.

Fig. 11(b)].](https://image.slidesharecdn.com/module2partilimitsfitsandtolerances-220311142811/85/Module-2-part-i-limits-fits-and-tolerances-27-320.jpg)

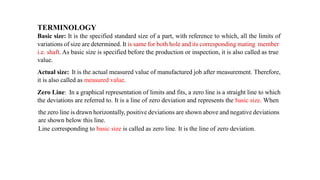

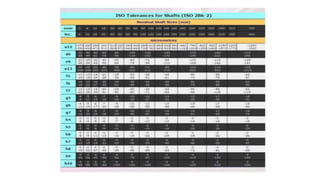

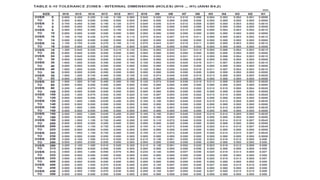

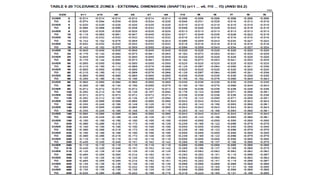

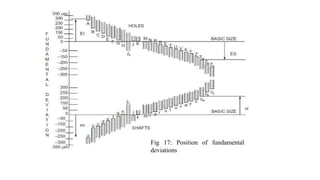

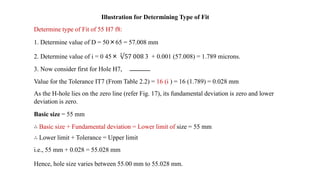

![4. Now consider for shaft 55f8,

Value for the tolerance IT8 (From Table 2.2) = 25 (i ) = 25 (1.789 microns) = 0.0447 mm

As the f-shaft lies below the zero line (refer Fig. 17), its fundamental deviation is the upper deviation.

Hence, the formula for fundamental deviation from Table 2.3 is = [−5.5 D 0 . 41 ].

−5.5 D 0 . 41 = = −5.5 (57.0.08) 0 . 41 = = −28.86 microns = −0.0288 mm

∴ Now, upper limit of shaft = Basic size + Fundamental deviation

= 55 mm + (−0.0288) = 54.9712 mm

And, lower limit of shaft = Upper limit of shaft + Value for the Tolerance IT8

= 54.9712 − 0.0447 = 54.9265 mm

Hence, shaft size varies between 54.9712 mm to 54.9265 mm. and hole size varies

between 55.00 mm to 55.028 mm.

5. To check the type of fit we have to calculate

Maximum clearance = 55.028 mm − 54.9265 mm = 0.1015 mm [∴ clearance exists] Minimum

clearance = 55.00 mm -54.9712 mm = 0.028 mm [∴ clearance exists]

6.Therefore, we can conclude that the type of fit of 55 H7f8 assembly results into ‘Clearance fit’.](https://image.slidesharecdn.com/module2partilimitsfitsandtolerances-220311142811/85/Module-2-part-i-limits-fits-and-tolerances-49-320.jpg)