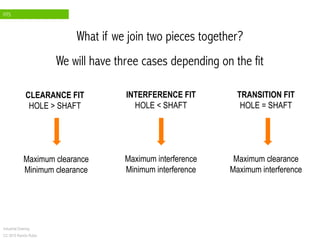

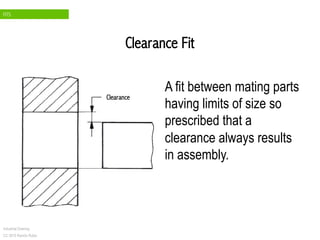

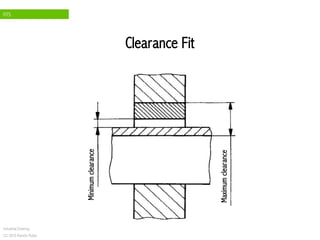

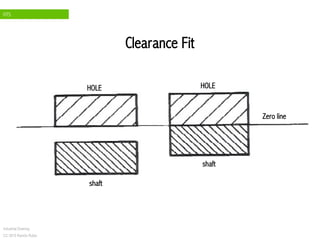

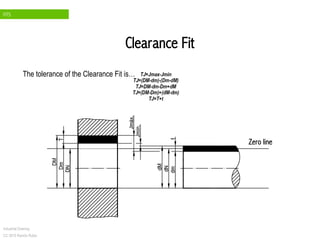

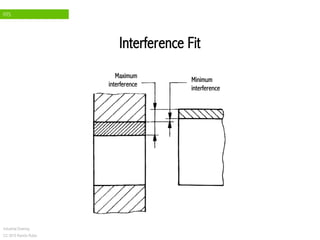

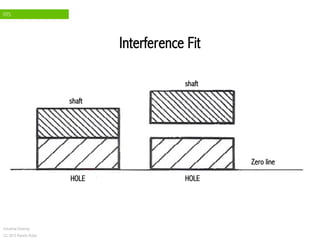

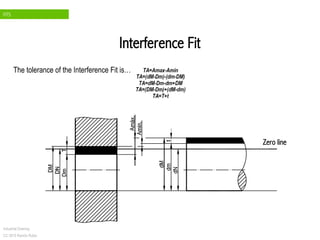

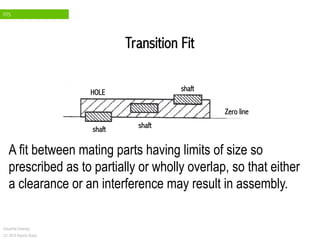

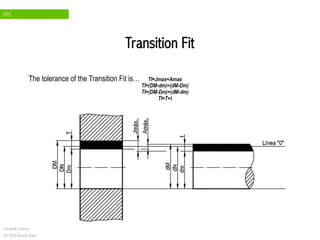

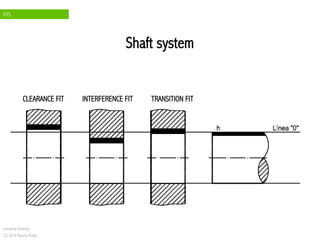

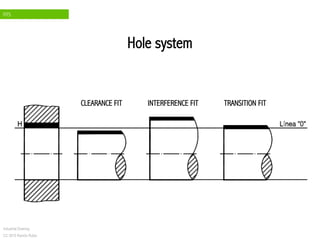

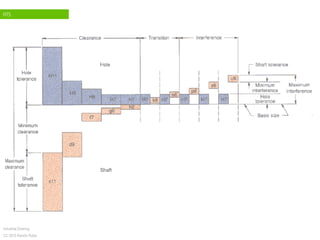

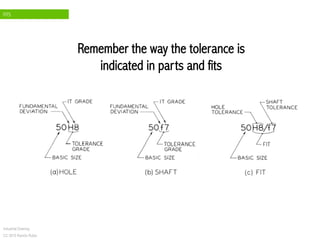

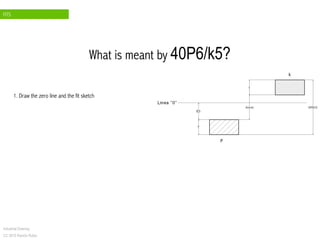

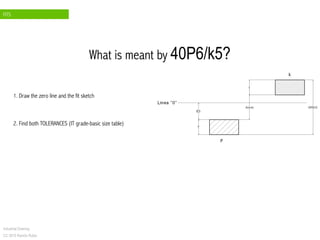

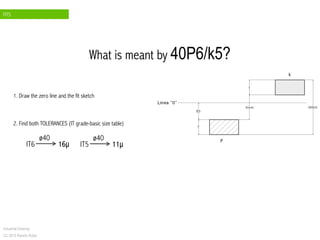

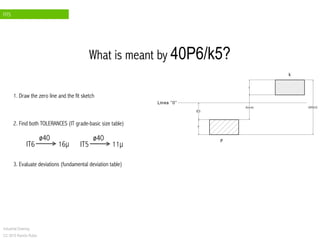

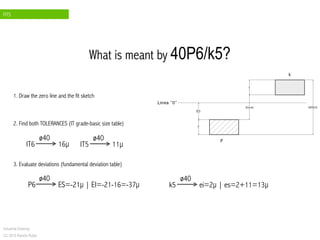

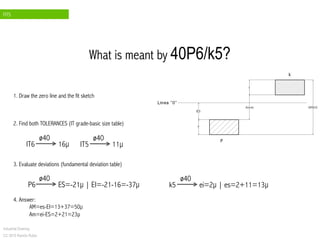

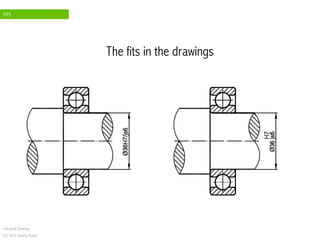

This document discusses different types of fits between mating parts in mechanical assemblies, including clearance fits, interference fits, and transition fits. For clearance fits, the hole is larger than the shaft to allow free movement. For interference fits, the hole is smaller than the shaft to create friction. Transition fits allow for either a clearance or interference when assembled. The document explains how to interpret fit tolerances written on drawings using International Tolerance grades and deviation tables.