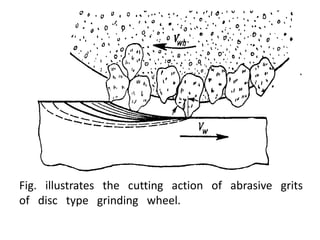

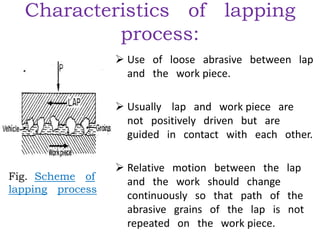

Surface finishing processes alter the surface of materials for aesthetic or functional purposes. Grinding is the most common abrasive machining process, using abrasive grits to cut material. Anodizing increases the thickness of the natural oxide film on aluminum, producing a corrosion-resistant and durable surface. Lapping uses loose abrasives to remove material within tight tolerances. Honing uses an abrasive tool that both rotates and reciprocates to smooth bore surfaces. These finishing techniques improve appearances, functionality, and sales value of products.