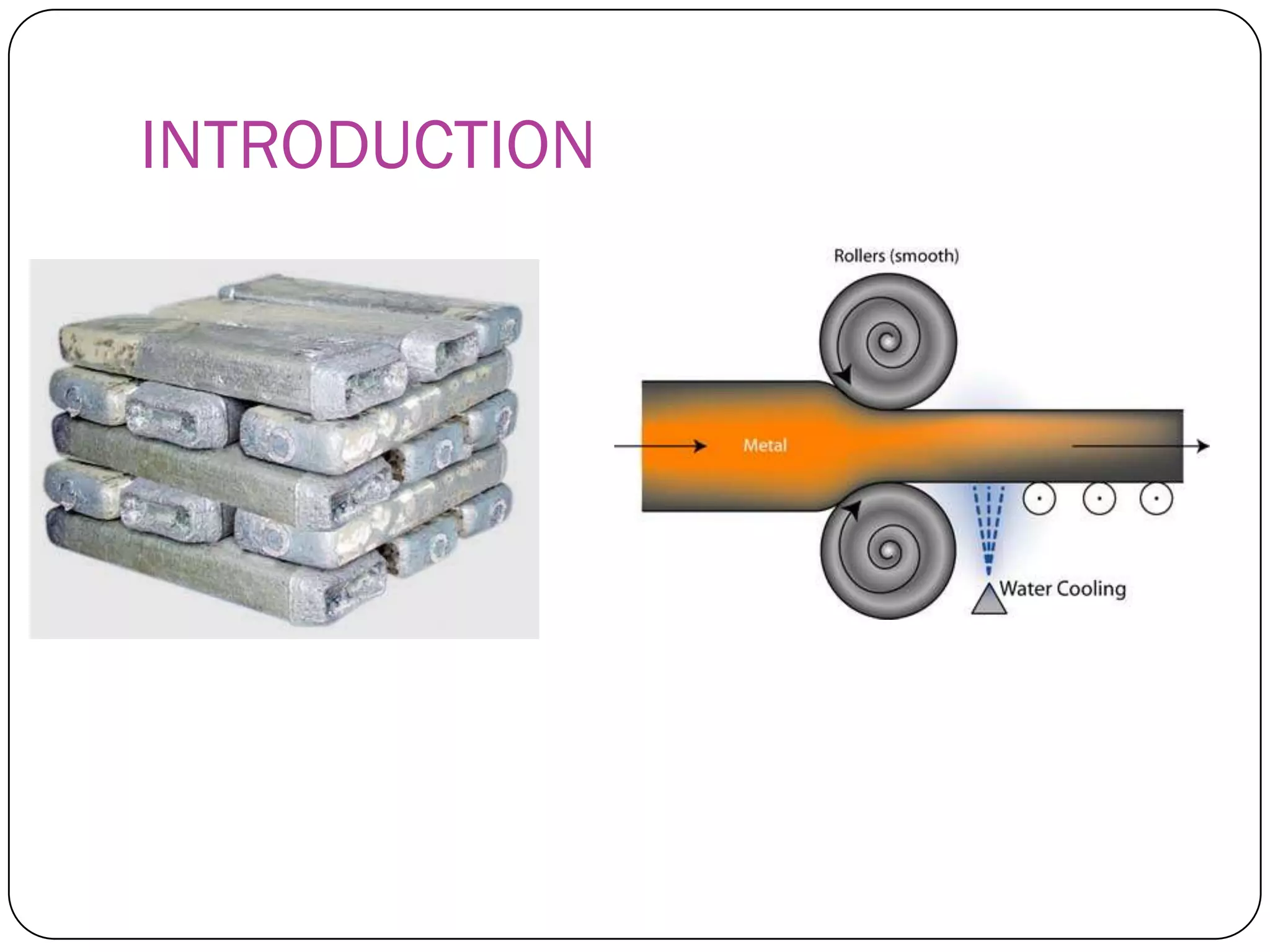

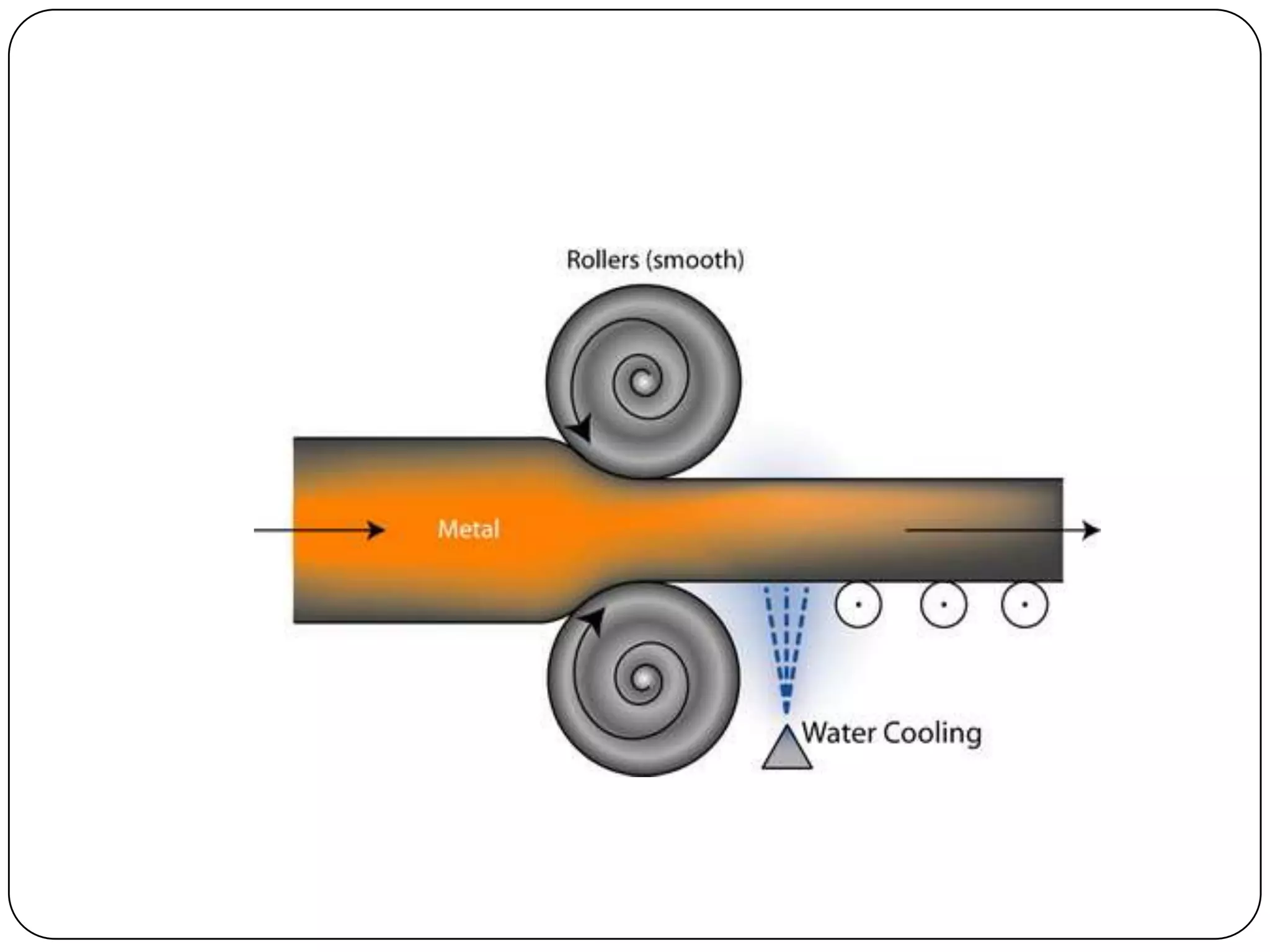

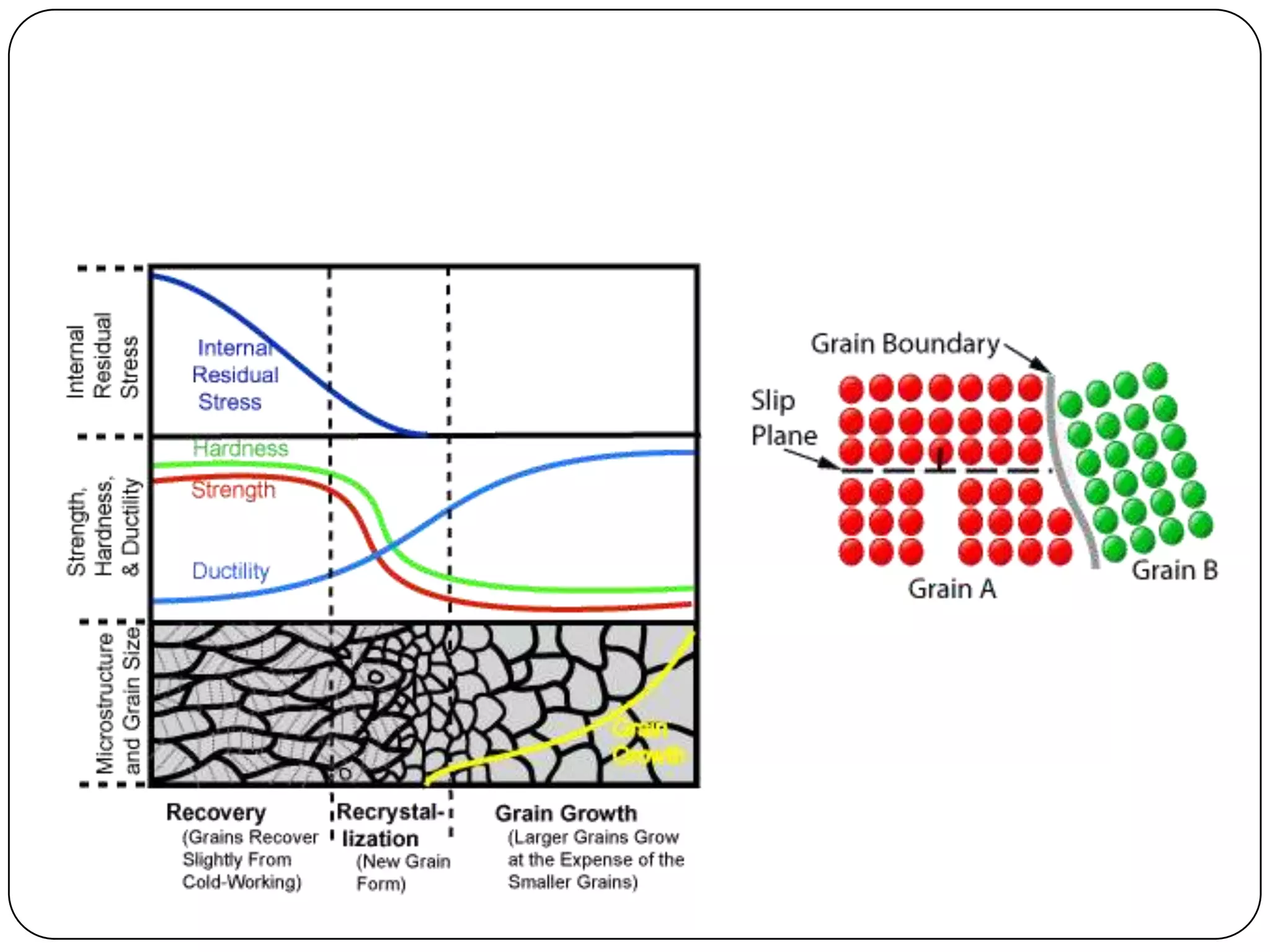

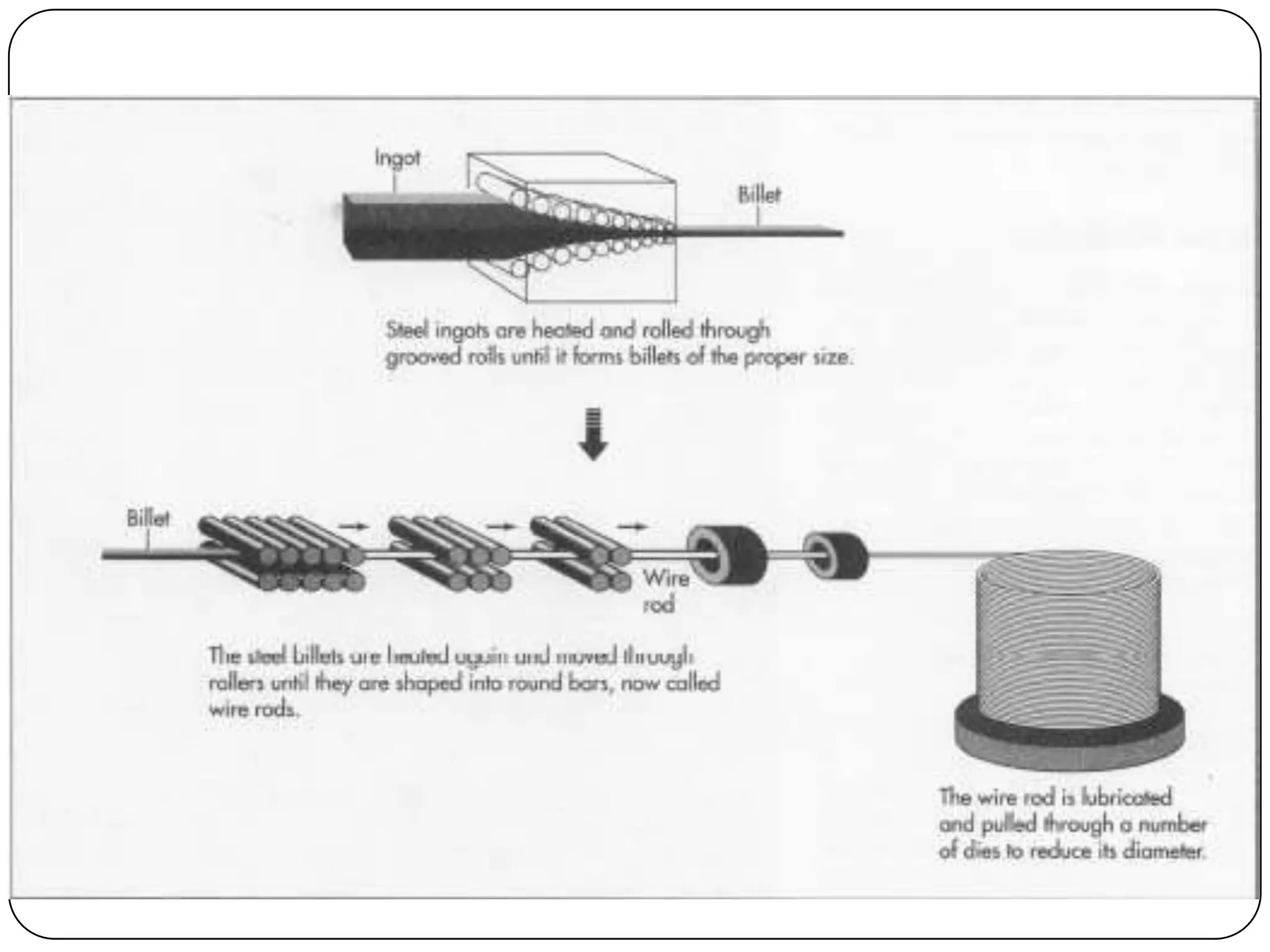

Bulk deformation processes like rolling are used to reduce the thickness or change the cross-section of metal workpieces. Rolling involves compressing metal between rotating rolls to produce flat products like plates and sheets. Hot rolling is done above the metal's recrystallization temperature to facilitate greater reduction in thickness than cold rolling. It produces a softer microstructure through recrystallization while cold rolling strengthens metals but makes them more brittle. Both processes impact the mechanical properties and microstructure of metals.