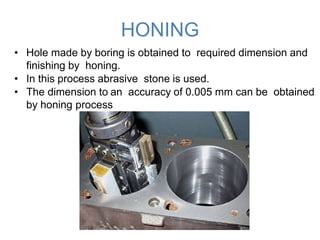

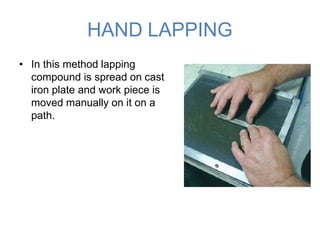

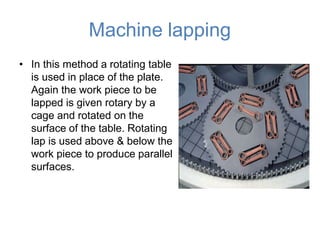

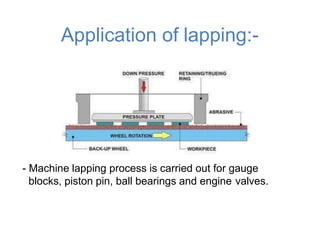

The document discusses super finishing processes which are used to remove defects from grinding operations and achieve a high surface quality. It describes three main super finishing processes: honing, lapping, and super finishing. Honing is used to finish bores and involves rotating abrasive stones to cut metal. Lapping uses abrasives and less pressure/heat to produce highly accurate flat surfaces. Super finishing is a type of honing that uses less pressure, higher speeds, and more lubricant to produce smooth external surfaces with minimal heat. The goal of these processes is to improve the dimensional accuracy and surface finish of parts.