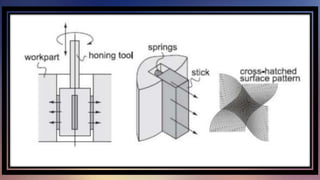

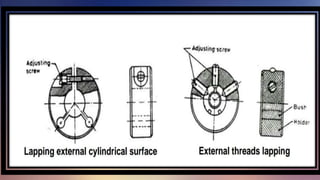

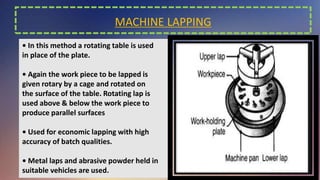

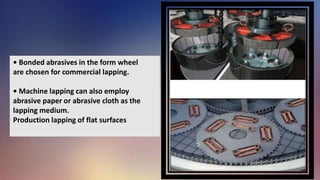

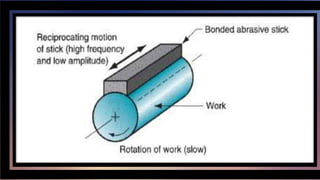

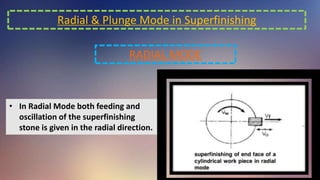

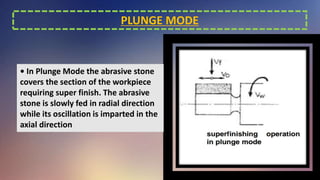

The document outlines superfinishing processes, focusing on honing, lapping, and superfinishing techniques used in precision machining. It details the processes involved, types of abrasives, and their specific applications in improving surface finish for various mechanical components. Key points include the differences in operational methods, the types of lapping, and the capabilities of each process in producing smooth surfaces.