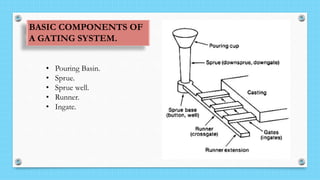

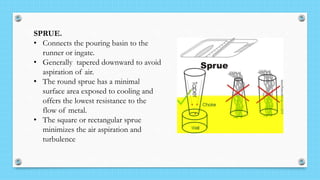

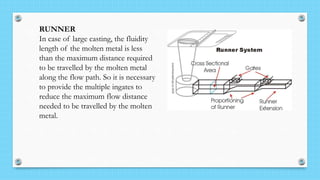

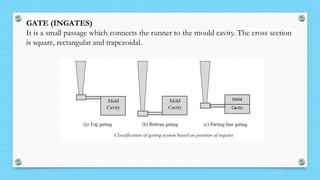

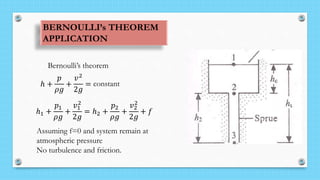

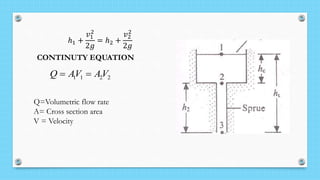

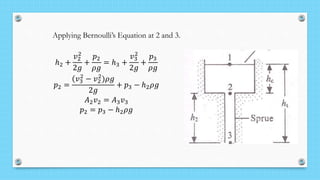

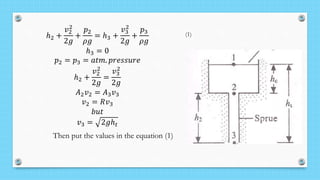

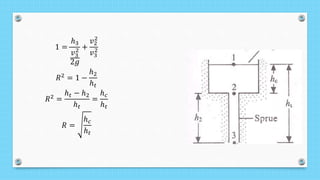

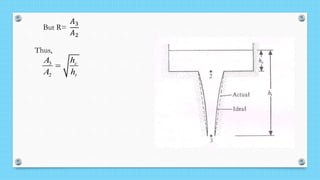

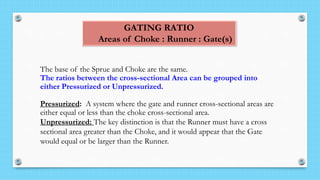

The document discusses the design of gating systems in metal casting, highlighting their role in directing molten metal to ensure uniform filling of casting cavities. It outlines key components such as the pouring basin, sprue, runner, and ingates, and provides guidelines for optimizing their configurations to minimize turbulence and improve flow efficiency. It also includes applications of Bernoulli's theorem and the continuity equation to analyze flow dynamics within these systems.