1) Super finishing processes such as honing, lapping, and super finishing are used to remove grinding defects from parts, obtain a desired surface finish, and improve geometry.

2) Finishing methods can involve material removal using fine machining, honing, and lapping, or forming without removal using glazing, blasting, and tumbling.

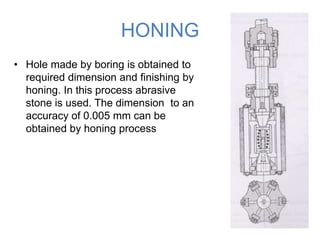

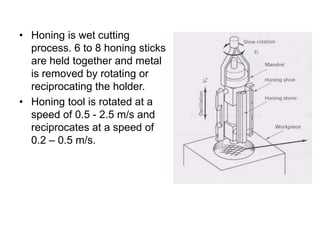

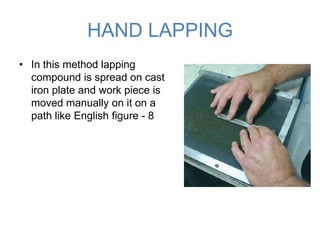

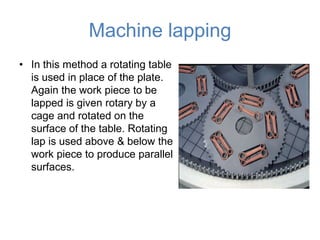

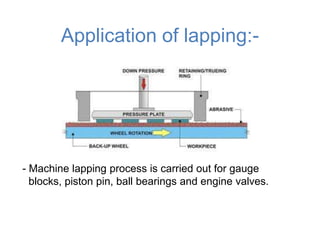

3) Specific super finishing processes include honing using abrasive stones, hand lapping by moving a workpiece on an abrasive plate, and machine lapping using a rotating table and rotating laps above and below the workpiece.