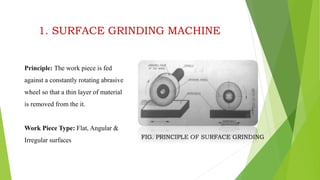

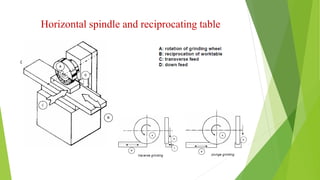

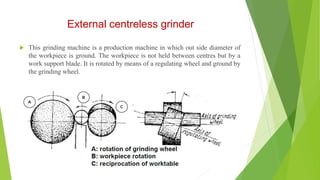

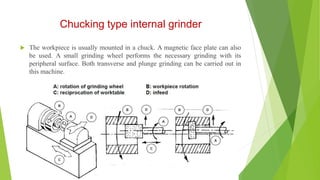

This document provides an overview of different grinding machine types used in manufacturing processes. It describes the principle of grinding where a rotating abrasive wheel removes a thin layer of material from a workpiece. The main types discussed are surface grinding machines, cylindrical grinding machines, centerless grinding machines, and internal grinding machines. For each type, the document outlines the basic principles and sub-types like horizontal or vertical spindle orientations for surface grinding or chucking vs planetary configurations for internal grinding.