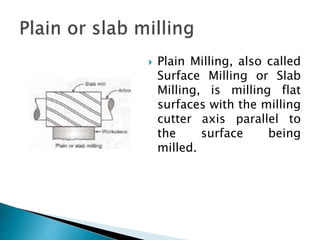

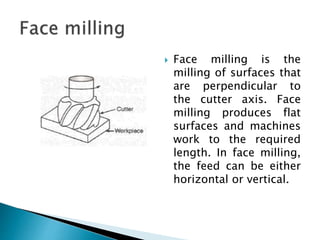

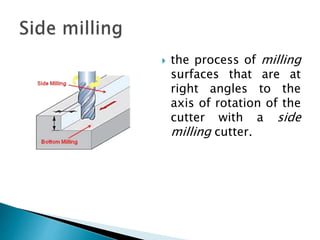

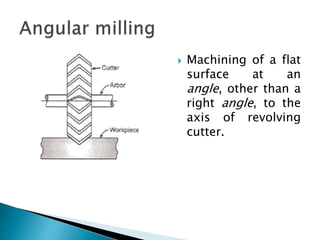

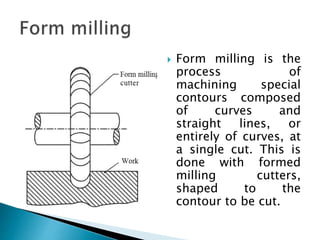

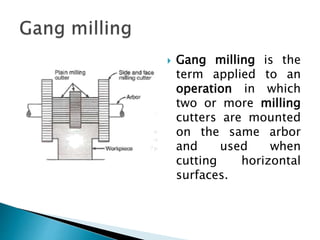

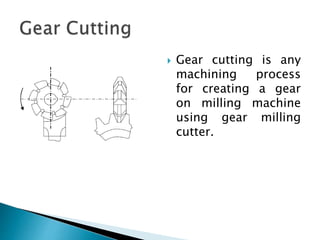

The document outlines various milling processes and techniques, including plain milling, face milling, and form milling, which involve removing material using rotary cutters. It details different types of milling cutters and operations like straddle and gang milling, as well as the specifics of machining surfaces at various angles. Additionally, it covers gear cutting as a specialized milling application.