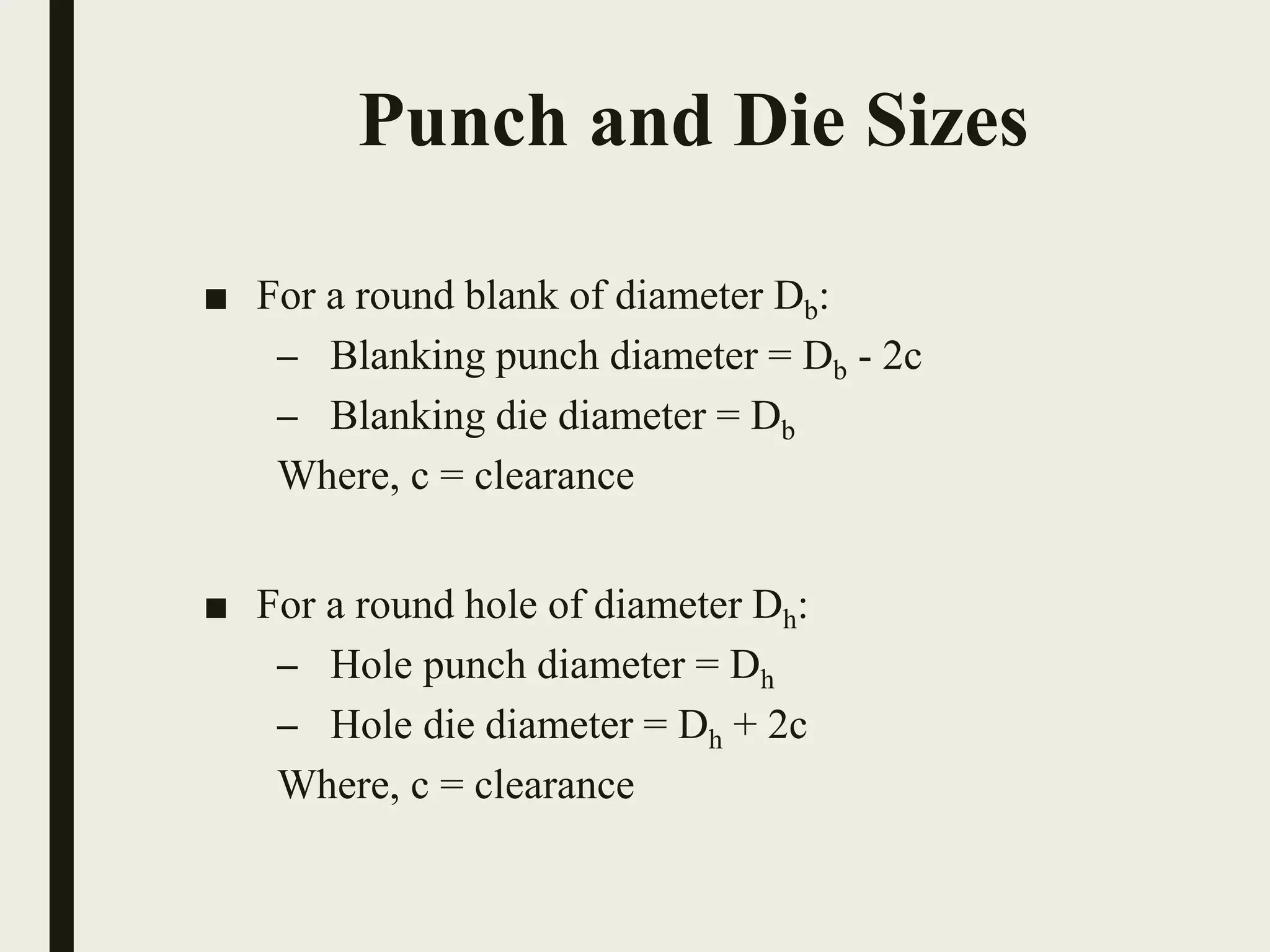

This document discusses various sheet metal forming processes. It describes cutting processes like shearing, blanking, and punching. It also describes bending, drawing, embossing, stretch forming, roll forming, and spinning. Sheet metal is commonly used to make parts for vehicles, appliances, furniture and more. Cutting is done using punches and dies in presses or shears. Proper clearance and tool sizes are important. Bending involves straining metal around an axis. Drawing forms complex curved shapes using punches and dies.