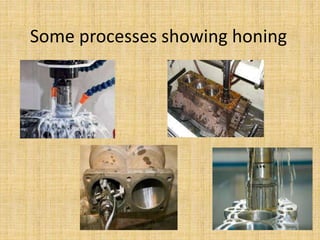

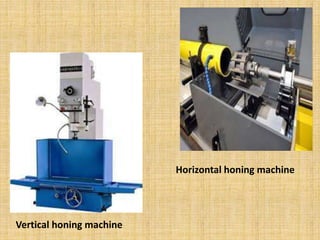

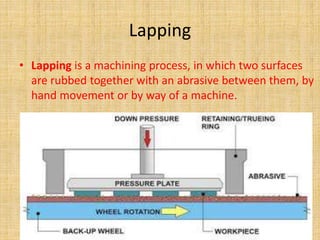

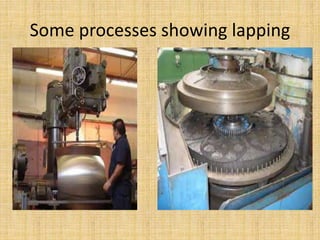

This presentation discusses various surface finishing processes. It provides details on honing, lapping, and super finishing. Honing uses an abrasive stone to improve the geometric form and surface texture of metal workpieces. Lapping rubs two surfaces together with an abrasive to achieve high precision and smooth finishes. Super finishing removes undesirable metal fragments to leave a smooth crystalline base. Each process is used to produce precise surfaces and dimensions for parts.