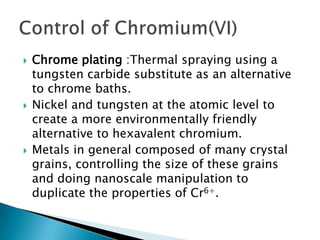

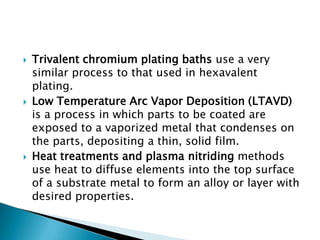

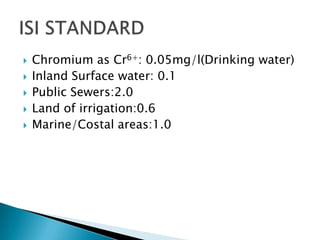

Chromium is a silvery transition metal that occurs naturally in ores like chromite. It has several important industrial uses including in stainless steel production and metal plating. Chromium exists in two main oxidation states, Cr3+ and Cr6+, with Cr6+ being more toxic and carcinogenic. Alternative plating methods are being developed to replace the use of hexavalent chromium due to its health and environmental risks.

![ Chromate salts contain the chromate

anion, CrO42−. Dichromate salts contain the

dichromate anion, Cr2O72−. They are

oxoanions of Cr in the oxidation state +6.

2[CrO4]2- + 2H+ ⇌ [Cr2O7]2- + H2O

The chromate ion is the predominant species

in alkaline solutions, but dichromate can

become the predominant ion in acidic

solution](https://image.slidesharecdn.com/chromiumppt-121115122324-phpapp01/85/Chromium-ppt-10-320.jpg)