The document discusses key aspects of quality management and inventory management from a procurement perspective. It covers four factors that determine quality levels, such as appropriate specifications and monitoring suppliers. Quality is defined in terms of performance, reliability, and conforming to requirements. Total quality management requires customer satisfaction and continuous improvement. Inventory exists to satisfy demand and prevent stockouts, but excess inventory incurs carrying costs. Managing inventory levels, order quantities, and reducing variability can lower costs.

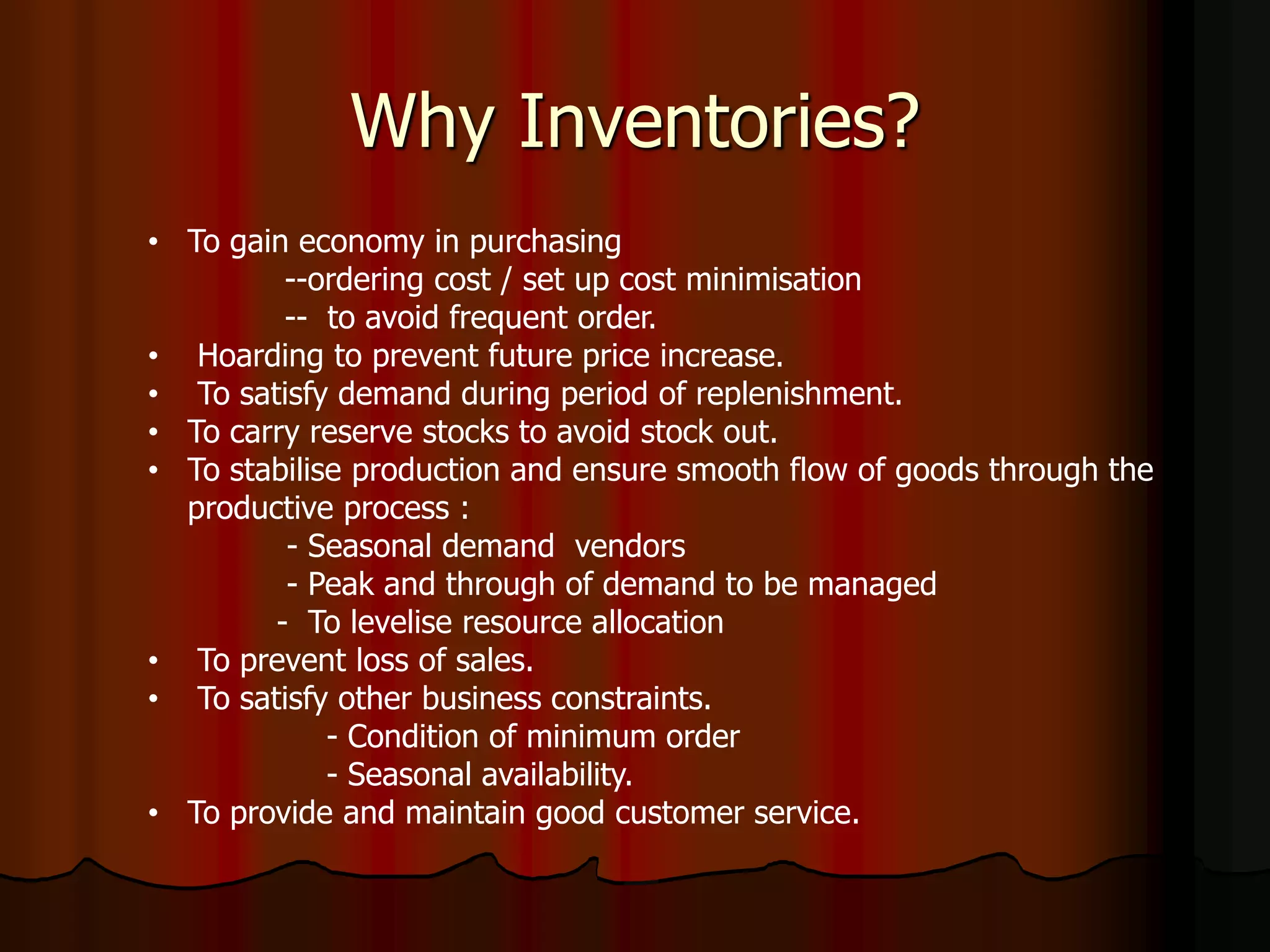

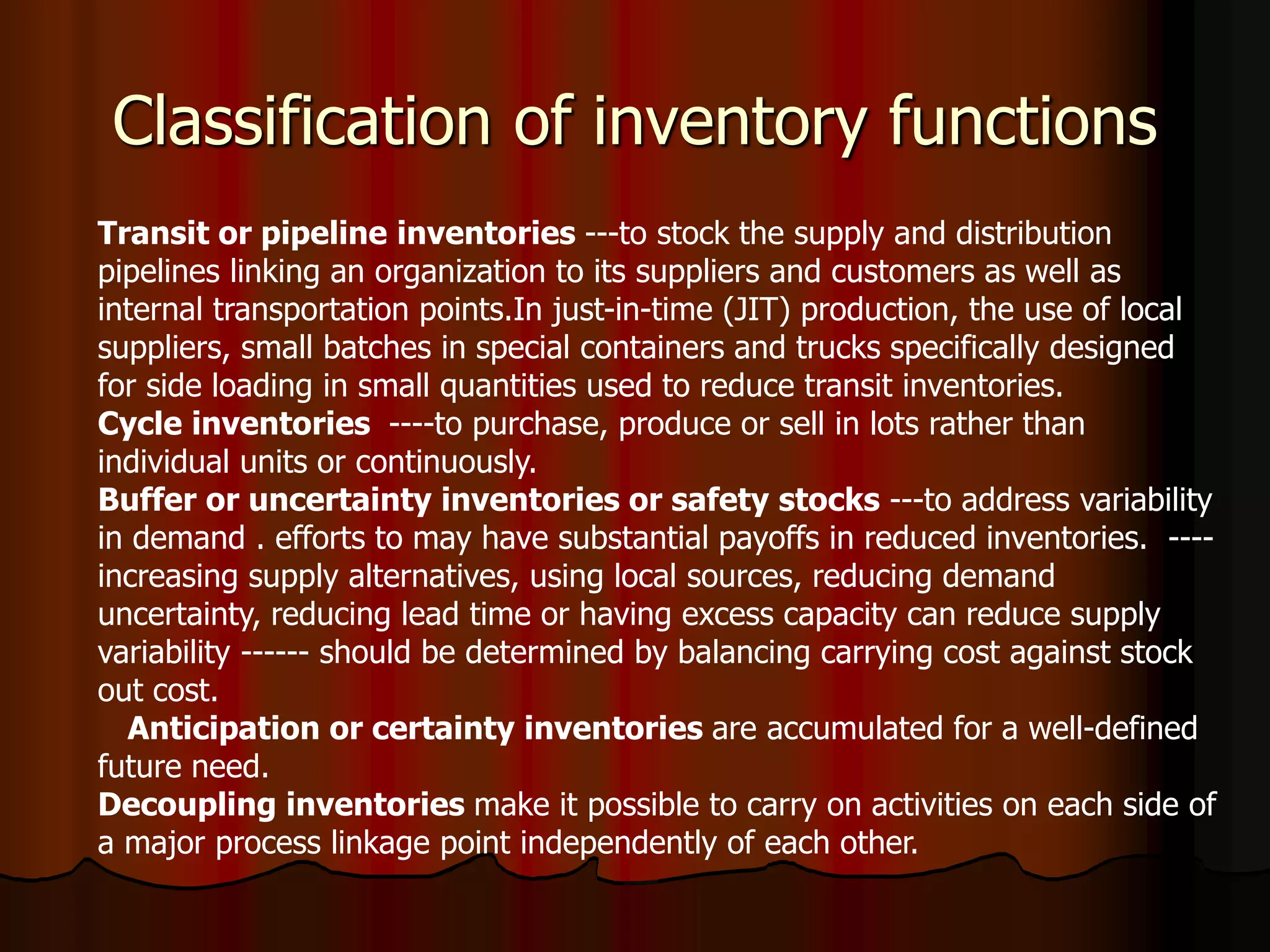

![Indicators of poor Inventory

Management

• Stock on hand is high compared to lead time * average consumption

• Frequent stock outs

• Backlog of orders or frequent failure of delivery commitments of high turn

over of customers due to cancellations.

• Uniform inventory policy to different items

• Adhoc policy on minimum stock maintenance

• Uneven production with frequent lay offs and over time working or break

down due to

• Non-availability of spare parts.]

• Discrepancies in stock counts.](https://image.slidesharecdn.com/qualitymanagment-150418015337-conversion-gate01/75/Quality-managment-19-2048.jpg)