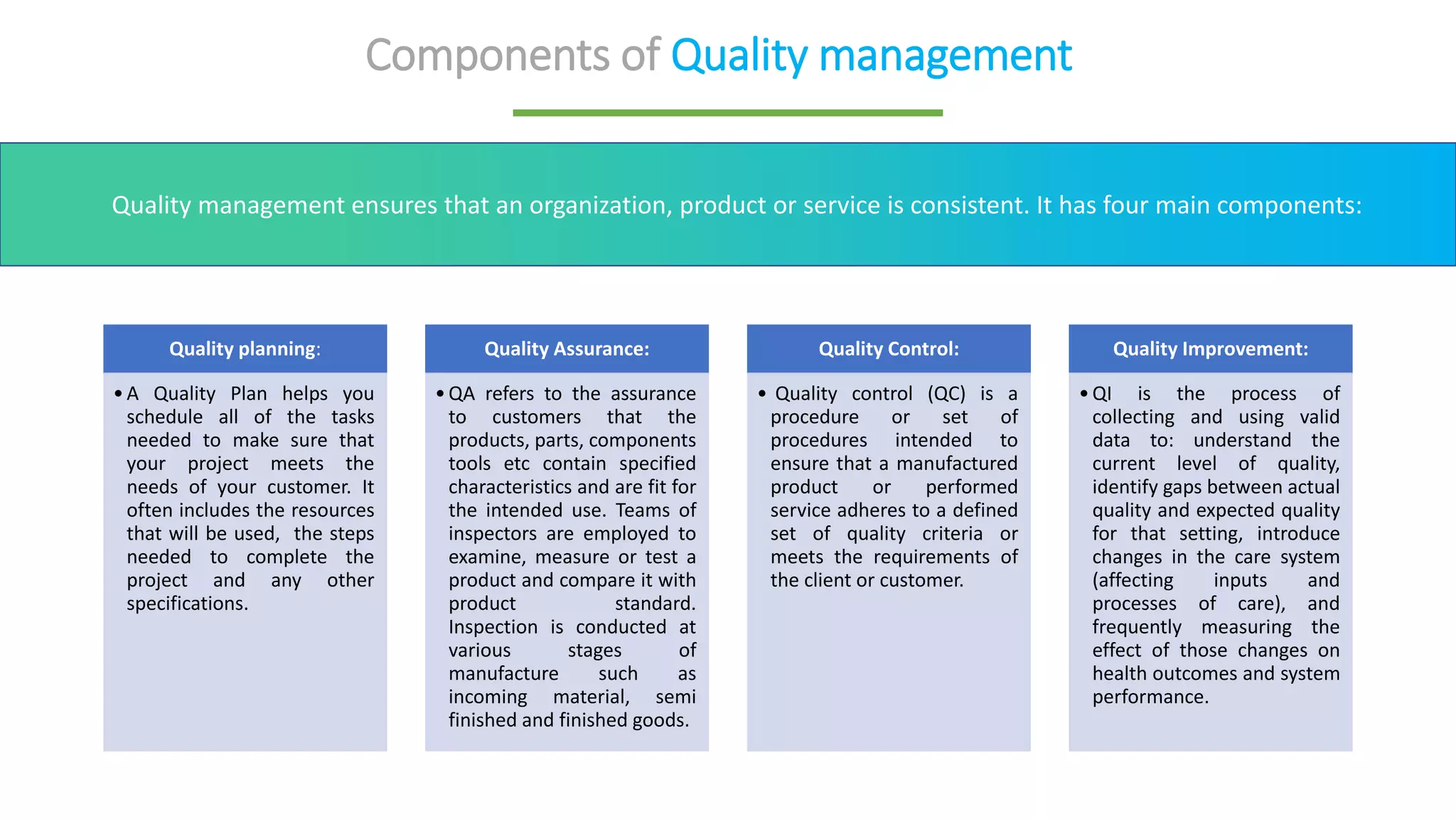

Japan faced criticism for low quality products in the 1960s but implemented effective quality management that transformed its reputation. Quality management ensures consistency through planning, assurance, control, and improvement. It uses tools like control charts, histograms, and flow charts. Customer perceptions of quality are measured using SERVQUAL criteria of reliability, assurance, tangibles, empathy and responsiveness. International standards like ISO 9000 define quality systems. Total quality management involves all employees continuously improving processes, products, services and culture through principles like customer focus, communication and fact-based decision making. The PDCA (plan-do-check-act) cycle is used for process improvement. Six Sigma aims to define, measure, analyze, improve and control quality within processes.