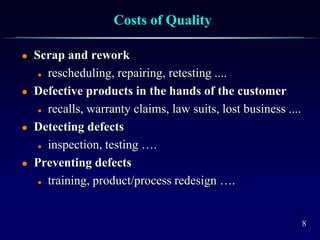

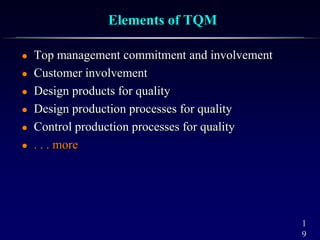

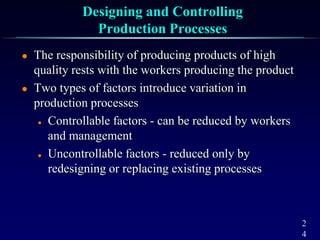

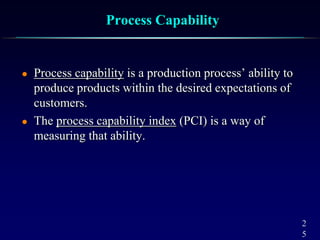

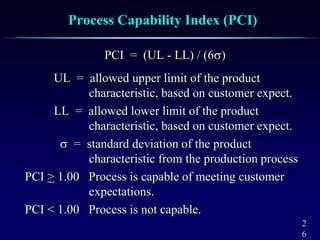

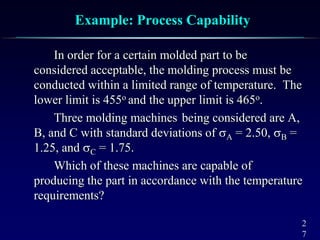

This document provides an overview of quality management and what it takes to achieve world-class status. It defines quality as meeting or exceeding customer expectations. Modern quality management involves adopting total quality management (TQM) programs that focus on continuous improvement, employee empowerment, and designing quality into products and processes. World-class companies implement extensive TQM programs to consistently deliver best-in-class quality and satisfy customers.