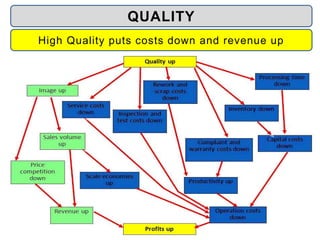

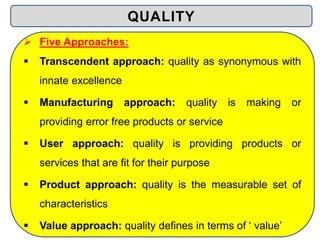

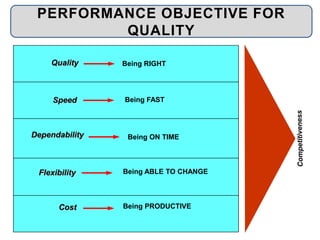

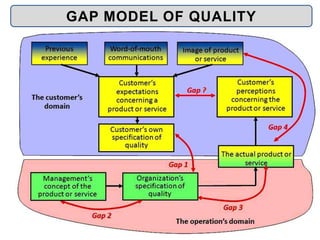

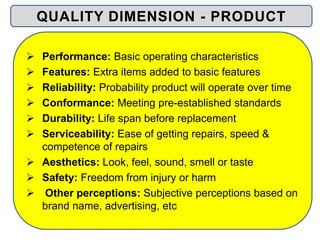

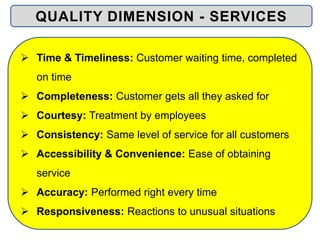

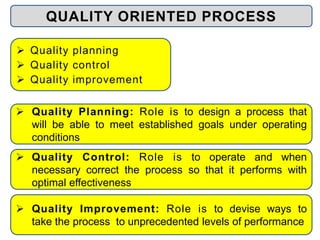

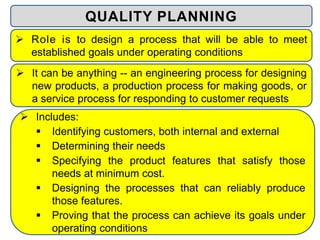

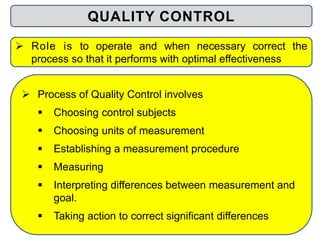

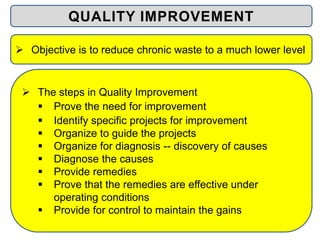

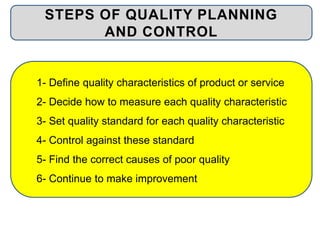

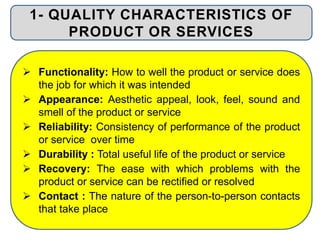

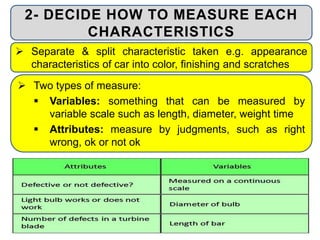

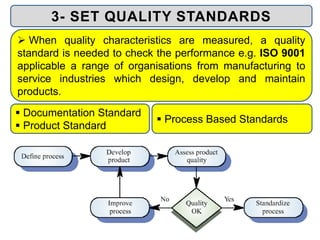

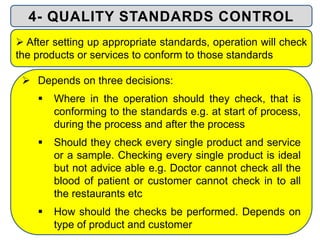

The document outlines key concepts of quality management, including objectives, dimensions, and control processes essential for meeting customer expectations. It discusses various quality models, characteristics, and the steps involved in quality planning and improvement. Additionally, it differentiates between quality control and quality assurance, emphasizing the importance of maintaining standards and continuously enhancing processes.