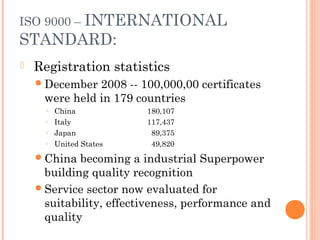

The document outlines the definition and principles of quality management systems, specifically focusing on the ISO 9000 standards that ensure product and service quality. It emphasizes the importance of documentation, management commitment, and continual improvement to achieve organizational objectives and customer satisfaction. The document also discusses the relationship between ISO 9000 and Total Quality Management (TQM), highlighting their compatibility and distinct origins.