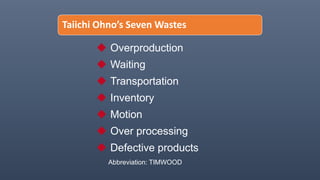

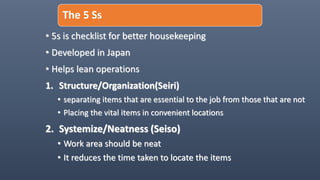

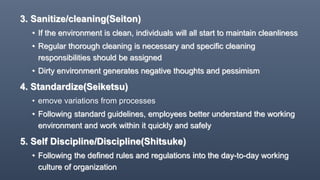

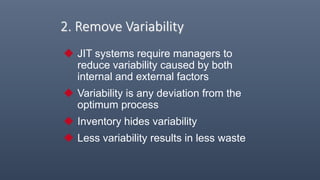

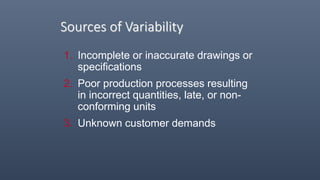

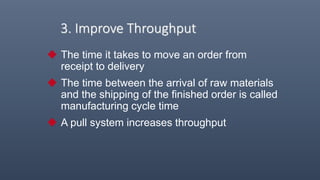

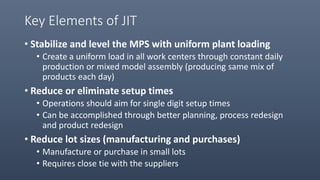

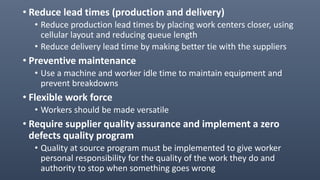

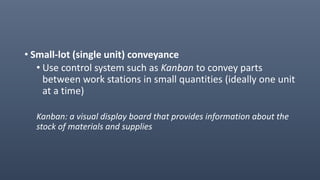

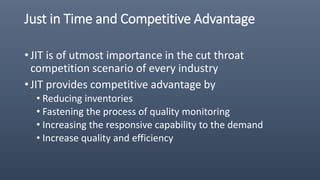

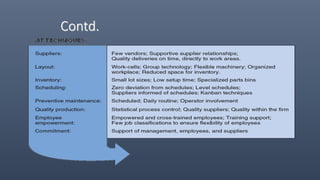

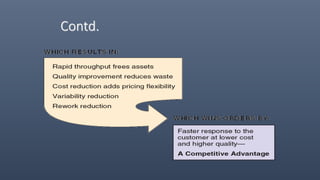

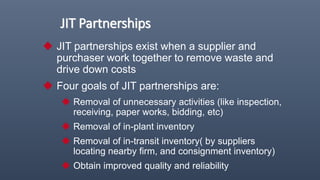

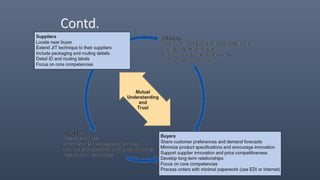

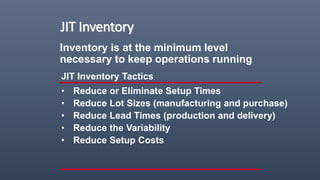

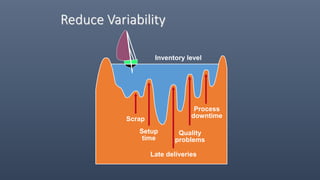

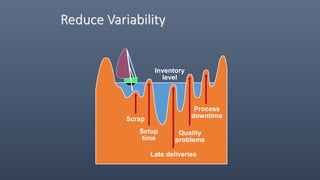

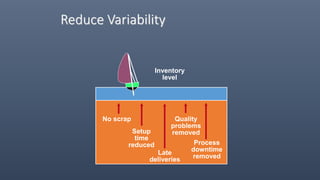

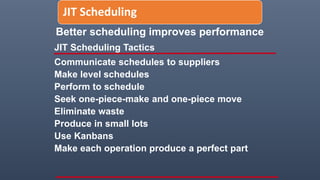

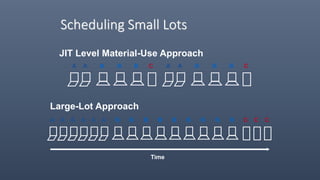

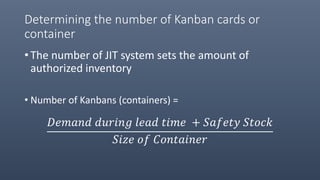

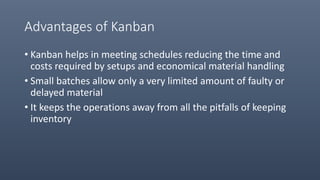

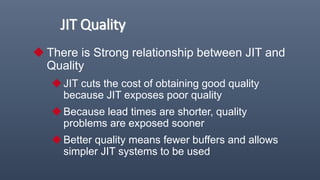

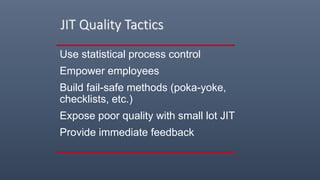

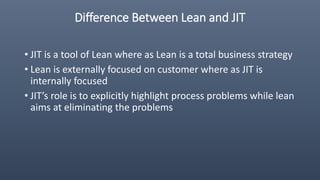

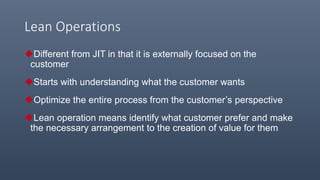

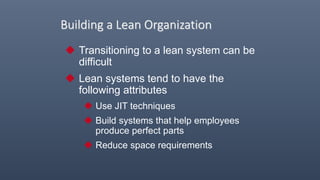

This document provides an introduction to Just-in-Time (JIT) and Lean operations principles. It discusses that JIT aims to produce the right part at the right time with no waste. Key aspects of JIT include eliminating waste, reducing variability, and improving throughput. Specific tactics covered include implementing the 5S methodology, using kanban systems for pull production, establishing JIT partnerships with suppliers, and focusing on small lot sizes, reduced set-up times and lead times to minimize inventory levels. The document also contrasts JIT with Lean operations and discusses approaches for implementing JIT and Lean principles in both manufacturing and service industries.