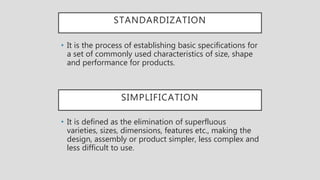

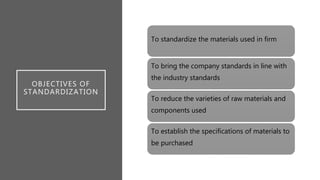

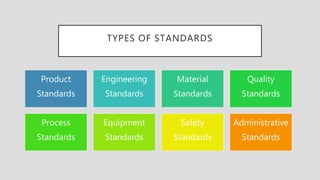

This document discusses variety reduction and standardization. It defines variety reduction as reducing the number of product, material, or part types within a given range to a lesser number that meets needs. Standardization establishes basic specifications for common product characteristics like size and shape. Simplification eliminates unnecessary varieties, sizes, and features to make products simpler. Benefits include better service, productivity, understanding problems, and inventory control with lower costs. Standardization aims for overall economy, convenience, uniformity, and quality assurance. It discusses levels, types, advantages, and disadvantages of standardization.