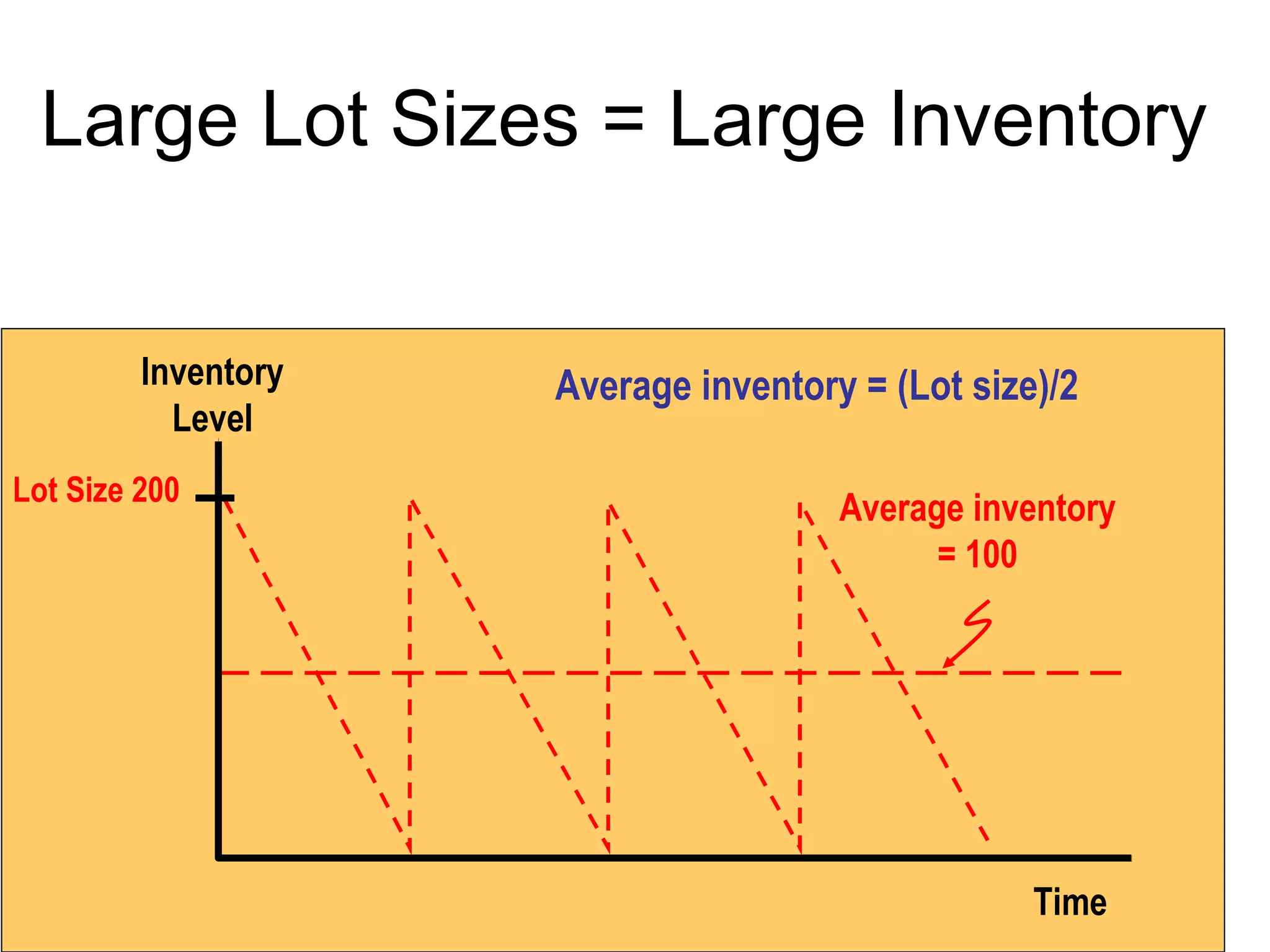

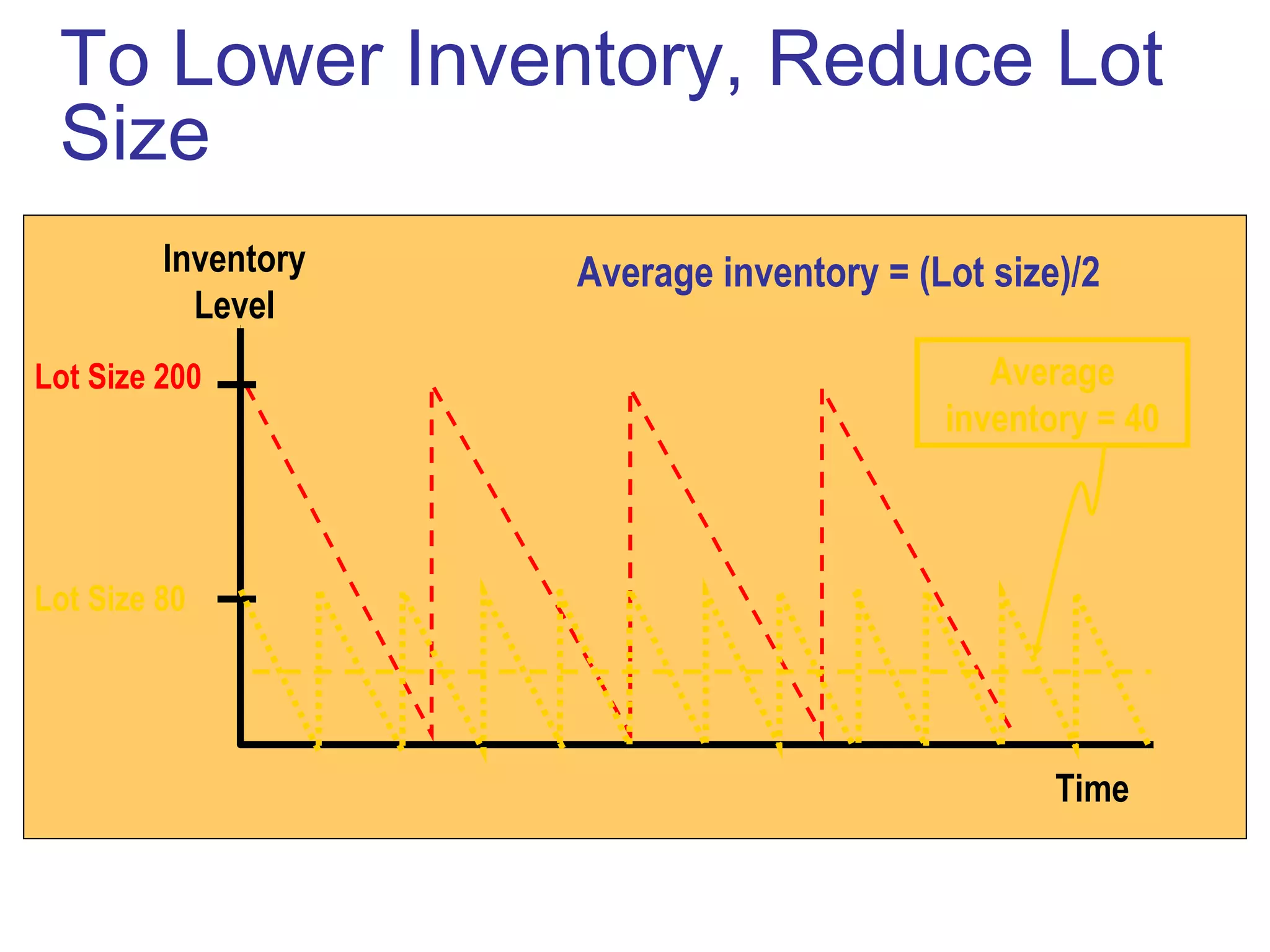

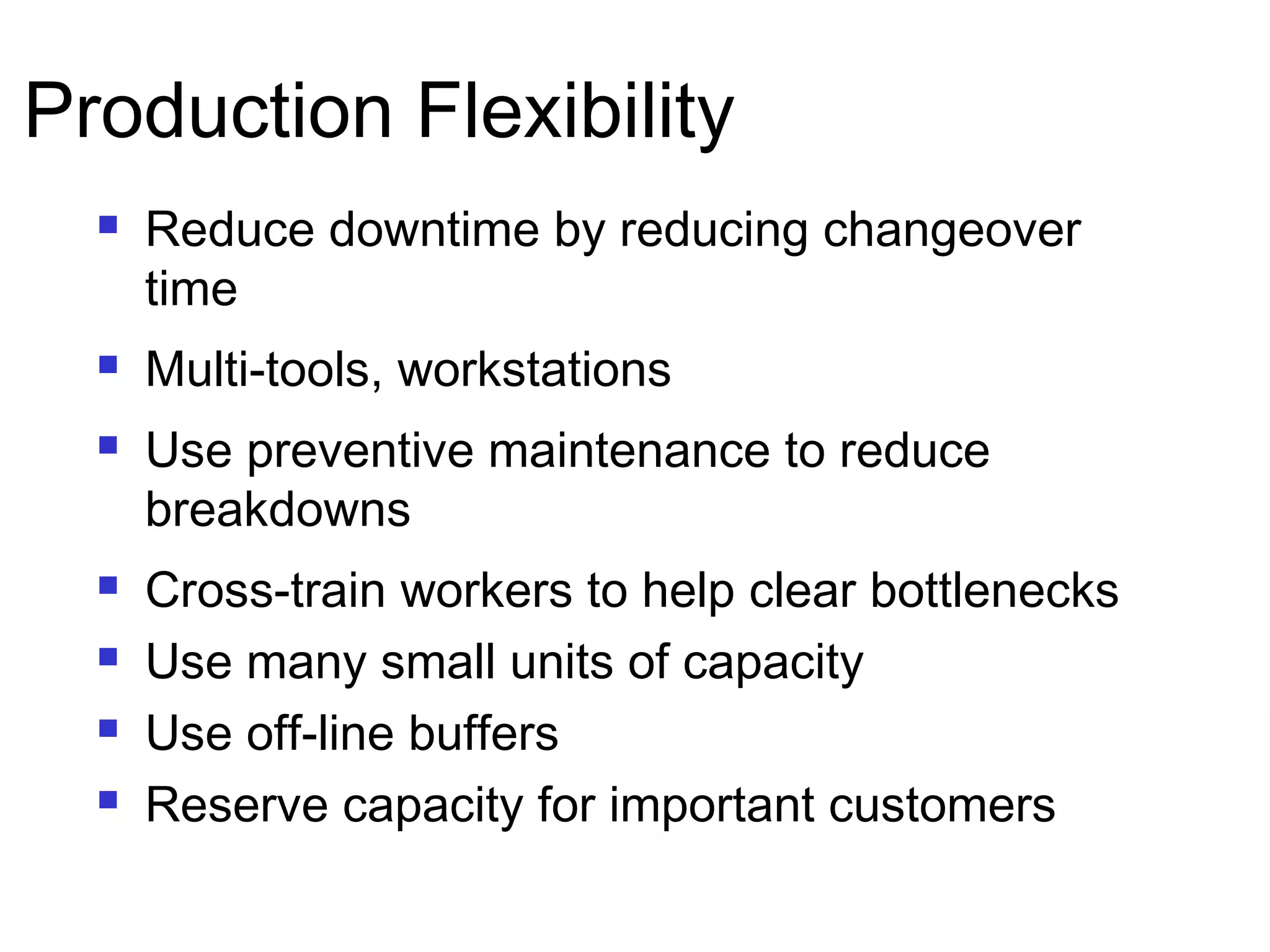

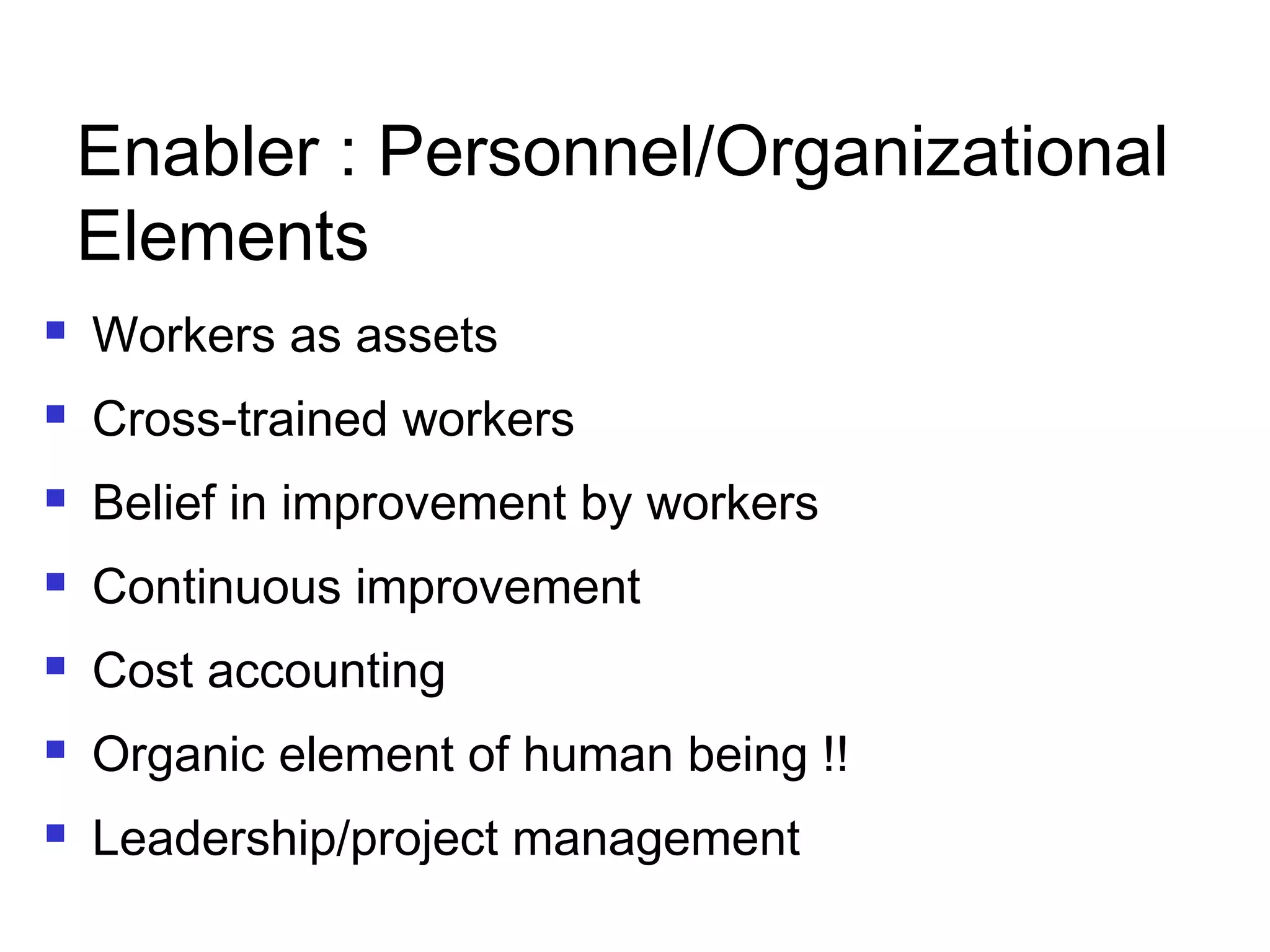

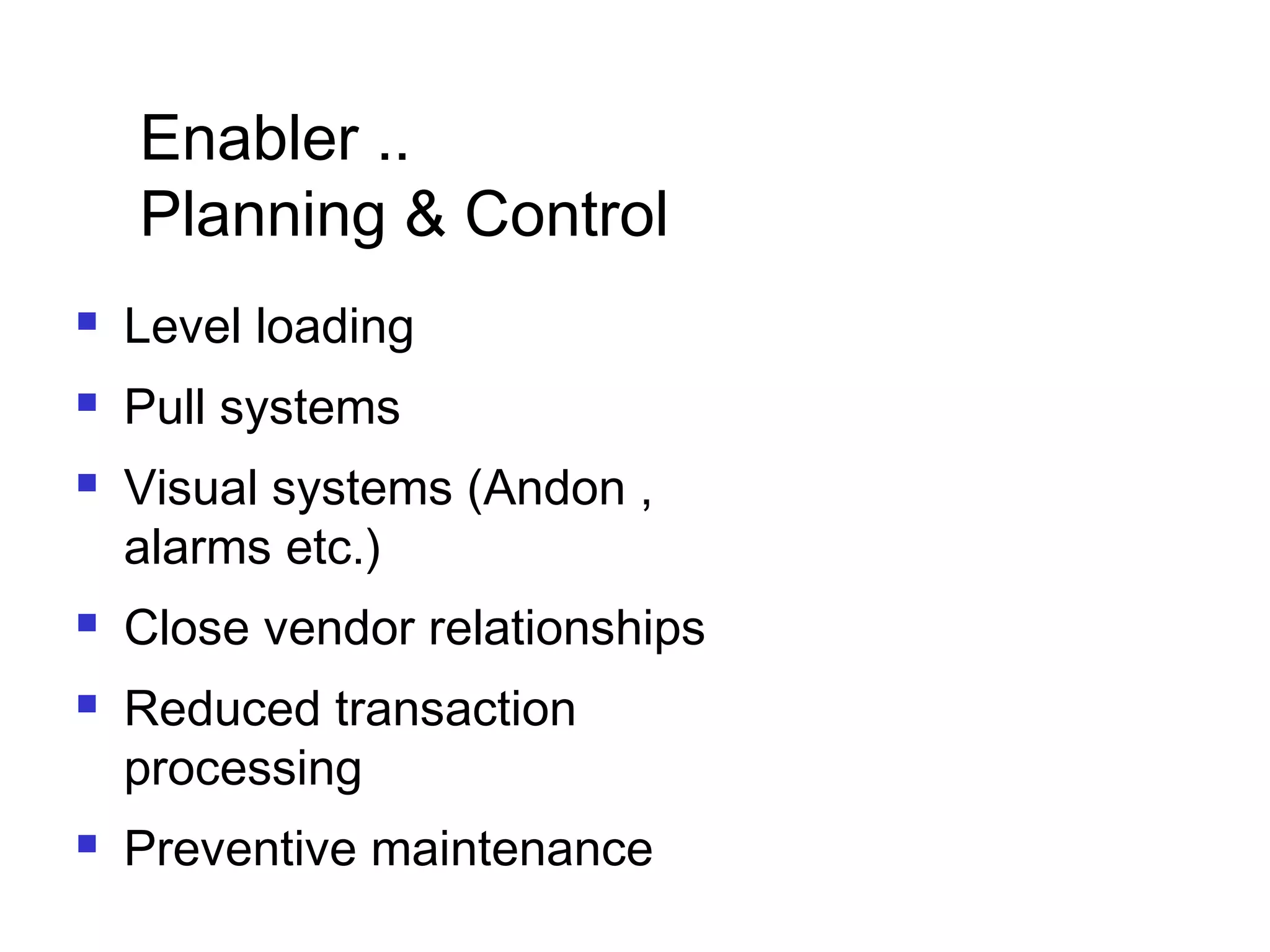

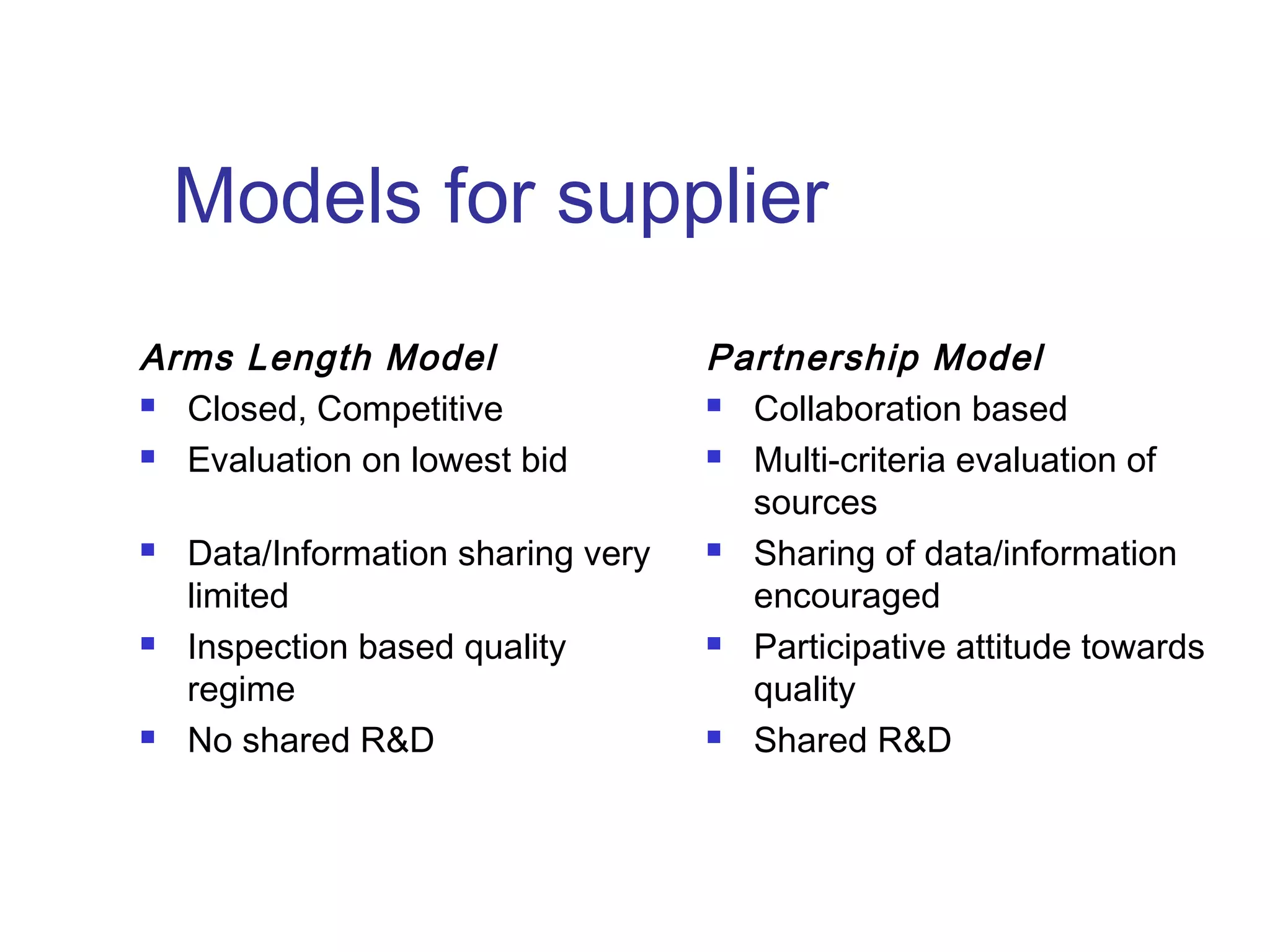

The document discusses the challenges and solutions of production systems, particularly highlighting the just-in-time (JIT) approach aimed at reducing waste and improving efficiency. JIT emphasizes producing only what is needed, when it is needed, and advocates for the elimination of inventory to expose underlying problems in the production process. Key components of successful JIT implementation include management commitment, collaboration with suppliers, process design, and continuous improvement efforts.