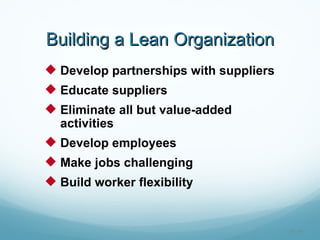

This document discusses key concepts related to Just-in-Time (JIT) and Lean operations including defining JIT, the Toyota Production System (TPS), Lean operations, the seven wastes, the 5Ss, JIT partnerships, variability reduction, and throughput improvement. It also covers JIT inventory techniques like pull systems, reduced lot sizes, and kanban. The overall goal of JIT and Lean is to eliminate waste and provide value to the customer.