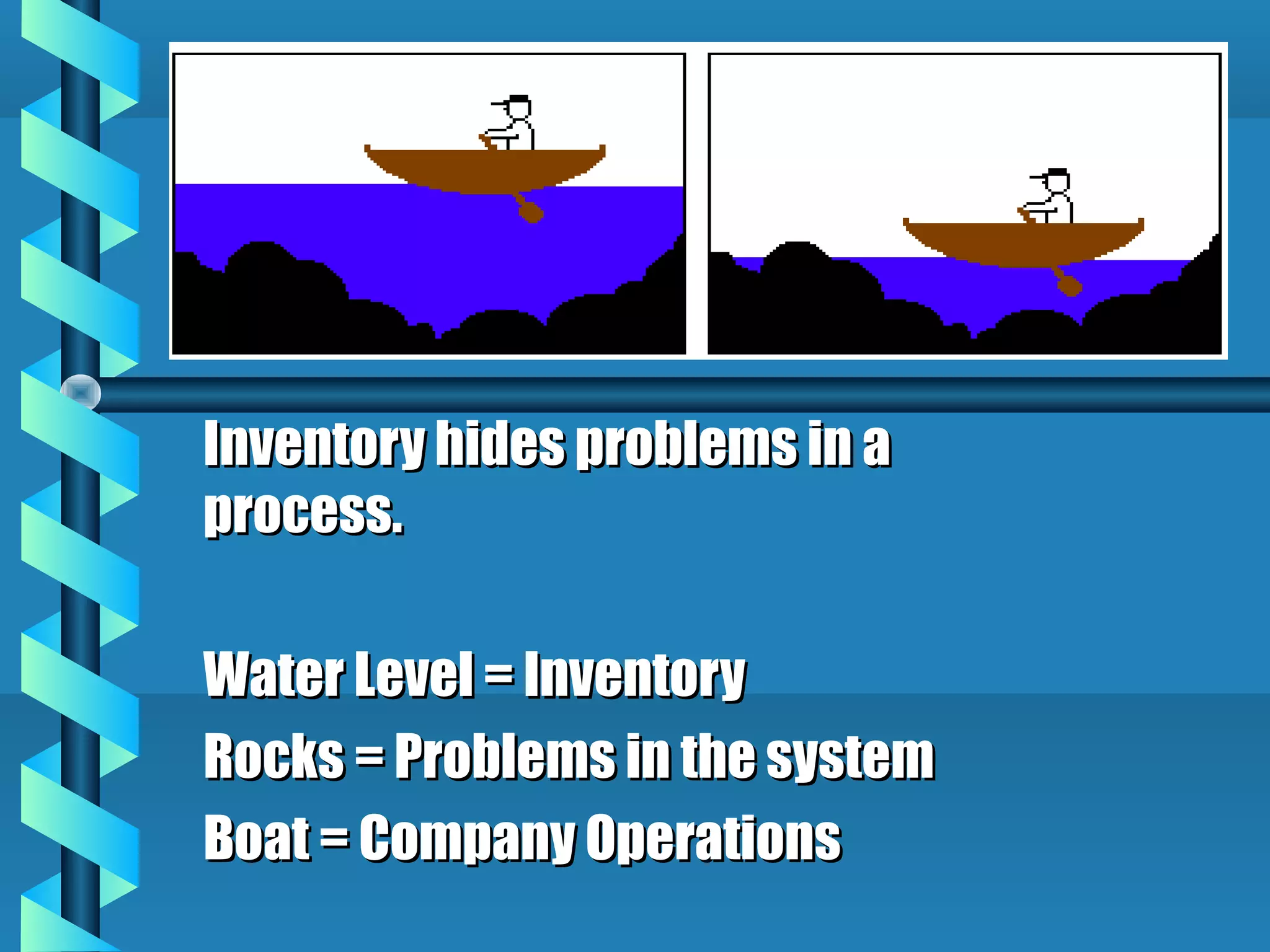

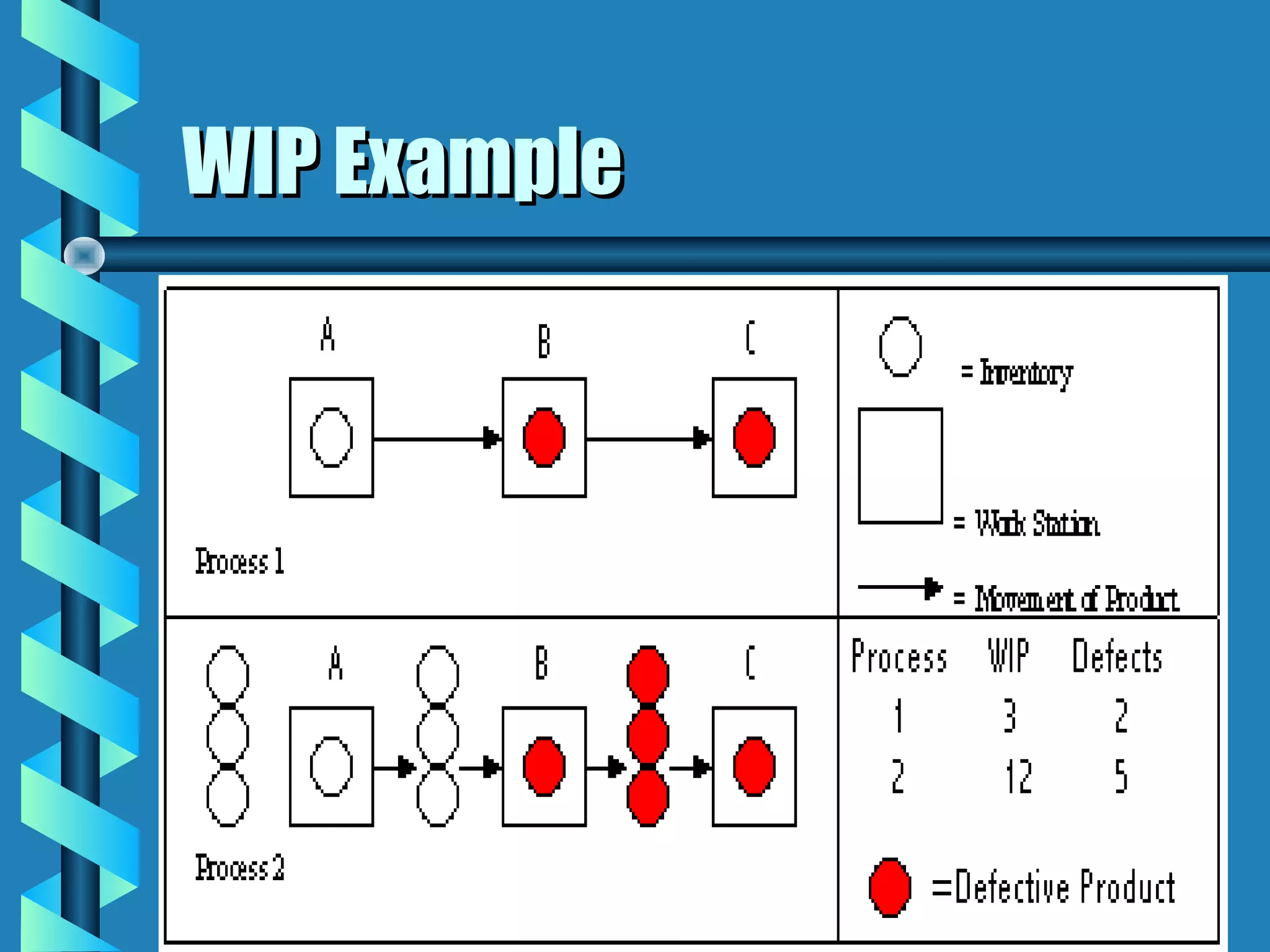

Just-In-Time (JIT) Manufacturing is a philosophy of continuous improvement that emphasizes prevention over correction and demands company-wide focus on quality. It originated in post-war Japan to address declining market share in automotive. The main principles include total quality management, production management based on a pull system with small lot sizes, close supplier relationships, low inventory, and human resource involvement. JIT aims to eliminate waste through continuous improvement.