Embed presentation

Downloaded 83 times

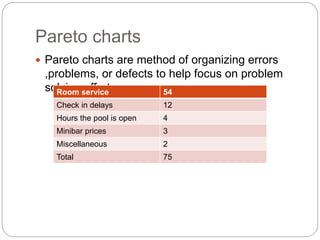

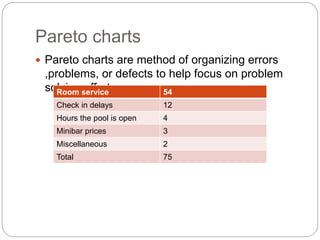

Total Quality Management (TQM) refers to a quality emphasis throughout the entire organization from suppliers to customers. The operations manager plays a key role in addressing service quality, including the tangible aspects, processes, customer expectations, and exceptions. TQM utilizes various statistical process control tools such as check sheets, scatter diagrams, cause-and-effect diagrams, Pareto charts, flow charts, histograms, and control charts to measure quality, identify issues and inspection points, prioritize problems, and monitor processes over time.