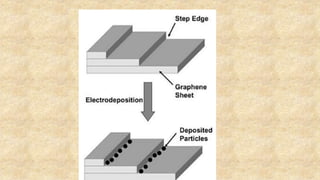

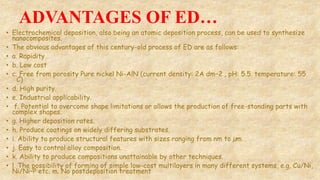

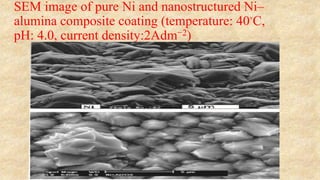

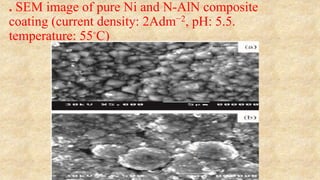

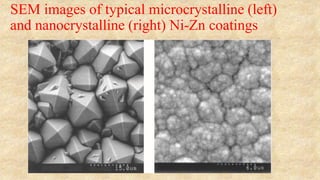

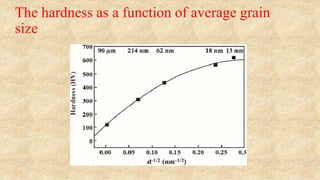

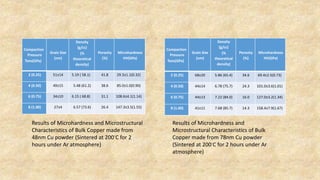

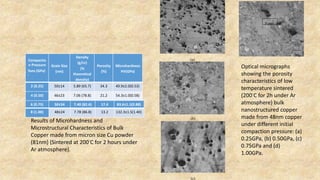

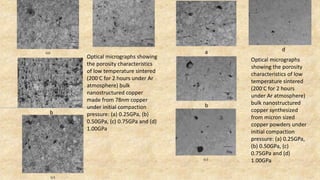

The document discusses methods for producing bulk nanostructured materials including plasma compaction and electrodeposition. Plasma compaction uses short, high-temperature processing to compact nanopowders into dense bulk materials while minimizing grain growth. Electrodeposition allows for the controlled production of nanostructured metal films and coatings through manipulation of deposition parameters. Both methods produce materials with superior mechanical properties due to nanoscale features and have advantages such as low cost, simplicity, and industrial scalability. Experimental results on consolidating copper nanopowders using plasma compaction showed that higher compaction pressures resulted in increased density, hardness, and mechanical properties.