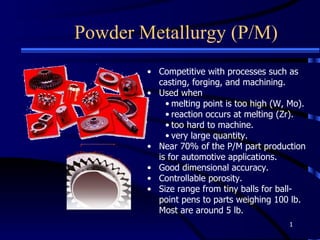

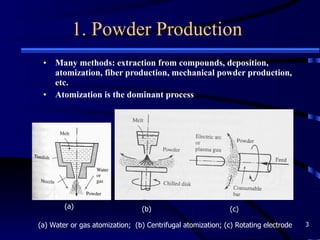

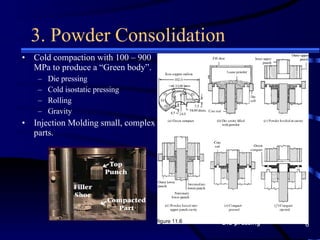

Powder metallurgy is competitive with other metal forming processes like casting, forging, and machining. It is commonly used to produce parts from metals with high melting points or that are difficult to machine. The basic steps of powder metallurgy are powder production, blending and mixing, powder consolidation through pressing or molding, sintering to strengthen bonds, and optional finishing. Near 70% of powder metallurgy production is for automotive applications due to its ability to produce parts with good dimensional accuracy and control porosity.